Combustion chamber of liquid fuel boiler

A liquid fuel and combustion chamber technology, which is applied in the directions of liquid fuel supply/distribution, combustion method, etc., can solve the problems of insufficient combustion of fuel, inability to monitor the internal state of the combustion chamber in real time, and poor monitoring of the combustion chamber system. achieve the effect of preventing detonation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

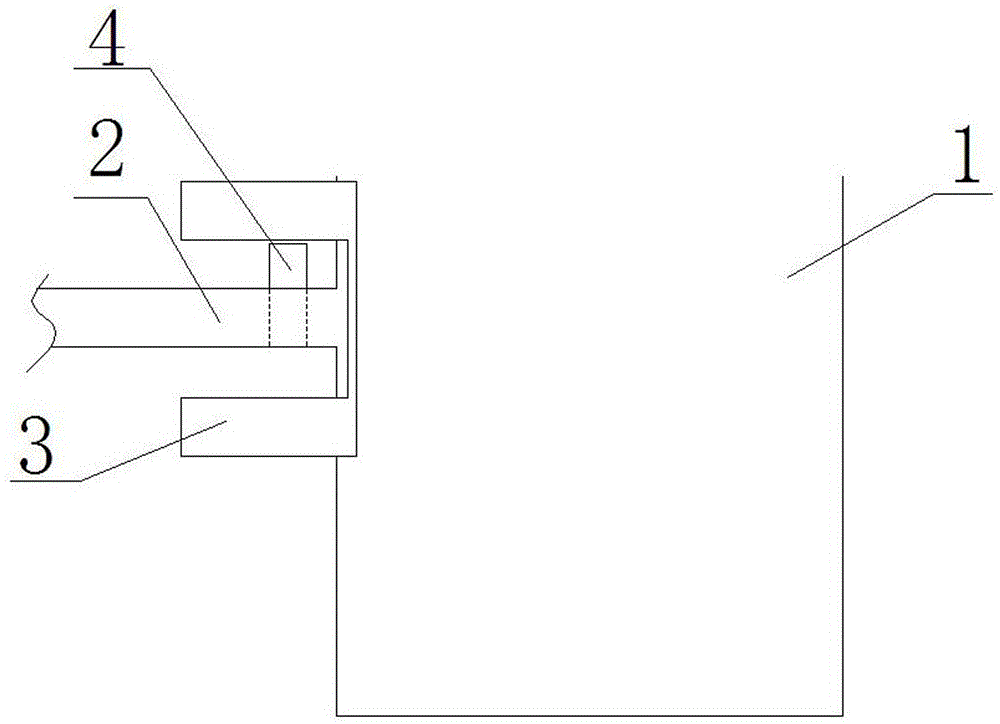

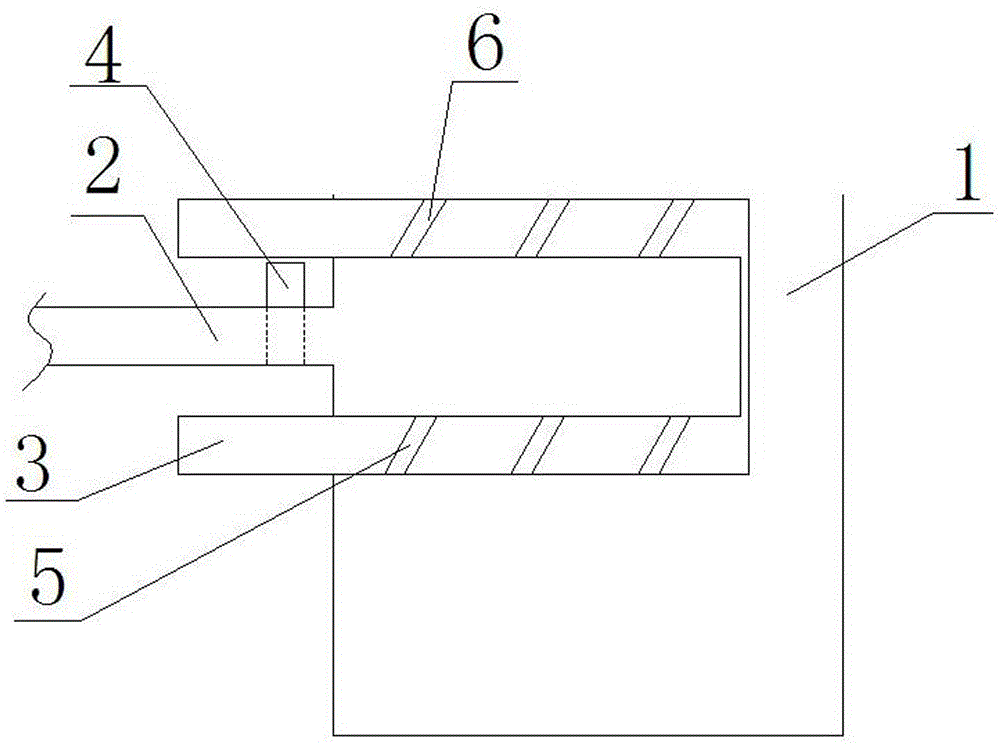

[0017] A combustion chamber of a liquid fuel boiler, comprising a combustion chamber 1; characterized in that: the upper part of the side wall of the combustion chamber 1 is provided with a plurality of liquid fuel feed pipes 2; A U-shaped telescopic fuel filling box 3 is provided. The U-shaped telescopic fuel filling box 3 includes an upper telescopic plate, a lower telescopic plate and a side plate; the upper telescopic plate and the lower telescopic plate are respectively connected to the liquid fuel feed pipe 2 Above and below the side plate; the top of the side plate is connected with the upper telescopic plate, and the bottom is connected with the lower telescopic plate; the upper telescopic plate is provided with a plurality of vent holes 6; the lower telescopic plate is provided with a plurality of leakage guide ports .

[0018] The liquid fuel feed pipe 2 is provided with an on-off valve 4.

[0019] Both the vent hole 6 and the leakage guide port 5 are provided with on...

Embodiment 2

[0021] The working principle of the present invention:

[0022] In the present invention, when adding liquid fuel to the inside of the combustion chamber 1, in order to prevent deflagration caused by adding liquid fuel when the furnace is not shut down or to prevent burning of the liquid fuel feed pipe 2, a U-shaped telescopic type is added Fuel filling box 3; the telescopic fuel filling box 3 is opened into the combustion chamber 1 when in use, the liquid fuel feed pipe 2 sends the liquid fuel to the telescopic fuel filling box 3, and then the liquid fuel feed pipe is closed After closing the valve on 2, open the vent 6 on the upper telescopic plate of the telescopic fuel filling box 3, and then open the leakage guide port 5 on the lower telescopic plate of the telescopic fuel filling box 3 to make the telescopic The liquid fuel inside the fuel filling box 3 flows into the combustion chamber 1, and the liquid fuel is added safely and effectively, so that no deflagration occurs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com