Solar photovoltaic panel applied to roof

A solar photovoltaic panel and photovoltaic panel technology, applied in the field of solar photovoltaic panels, can solve the problems of photovoltaic panel bracket damage, erosion, inconvenient maintenance, etc., and achieve the effects of extending service life, reducing contact, and facilitating maintenance and inspection work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

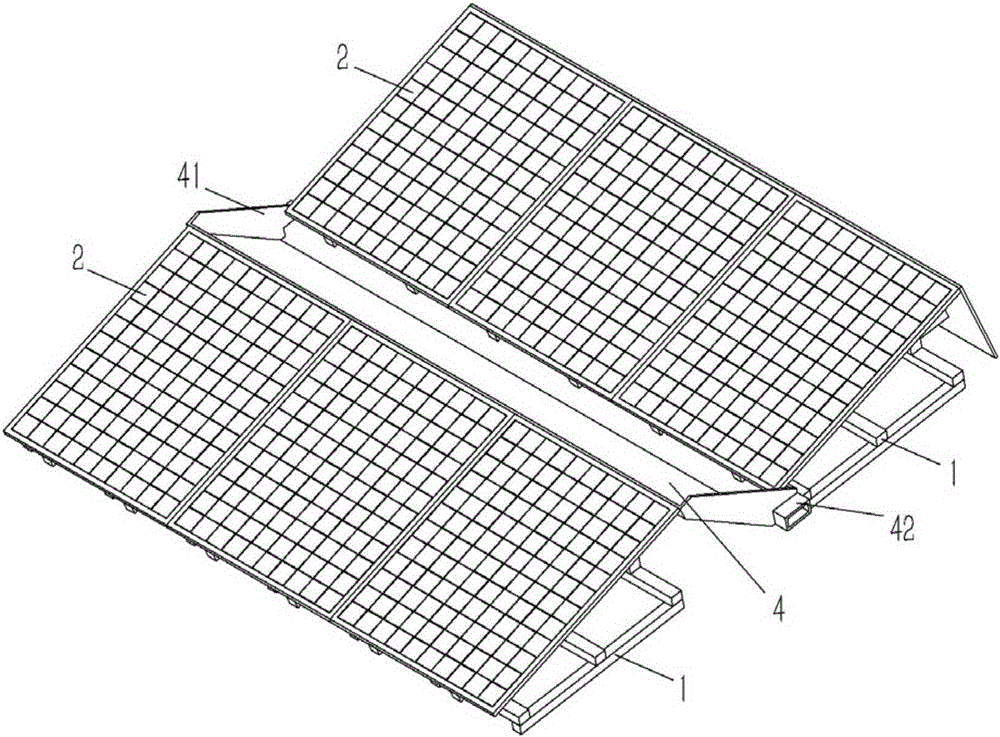

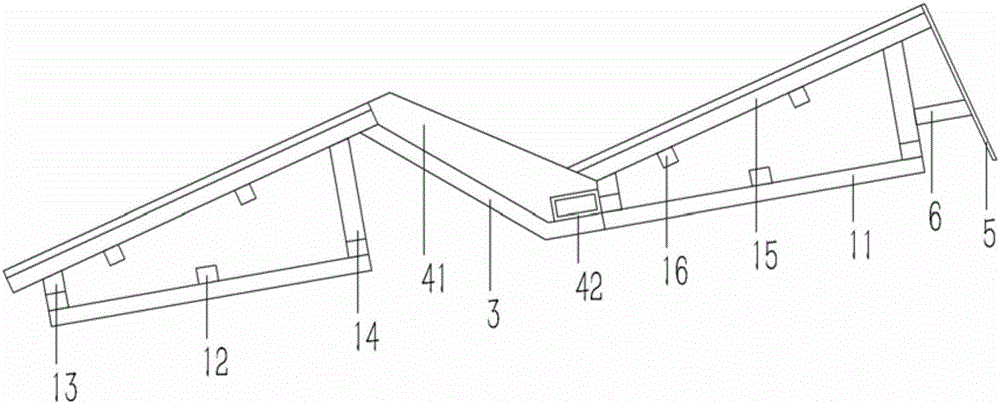

[0019] Example: see figure 1 , 2 As shown, a solar photovoltaic panel applied to the roof includes a plurality of photovoltaic panel brackets 1, and the photovoltaic panel bracket 1 is fixed with an inclined photovoltaic panel 2. The photovoltaic panel brackets 1 are fixed on the roof in a plurality of rows. The board support 1 is composed of a longitudinal bottom rod 11, a cross rod 12, a front support rod 13, a rear support rod 14 and a C-shaped channel steel 15. A number of supports are installed between the photovoltaic panel supports 1 between two adjacent rows. Rod 3, the upper end of the supporting rod 3 is fixed on the C-shaped channel steel 15 of the previous row of photovoltaic panel support 1, and the lower end of the supporting rod 3 is formed with a folding rod, and the folding rod is fixed on the cross bar 12 of the next row of photovoltaic panel support 1 On; the supporting rod 3 is fixed with a water tank 4, the upper side of the water tank 4 is fixed on the phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com