Shoemaking process of integrally molded shoe

An integrated and crafted technology, applied in the direction of shoemaking machinery, footwear, footwear, etc., can solve problems such as damage and degumming, many production equipment, and insufficient tightness of shoe uppers and soles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

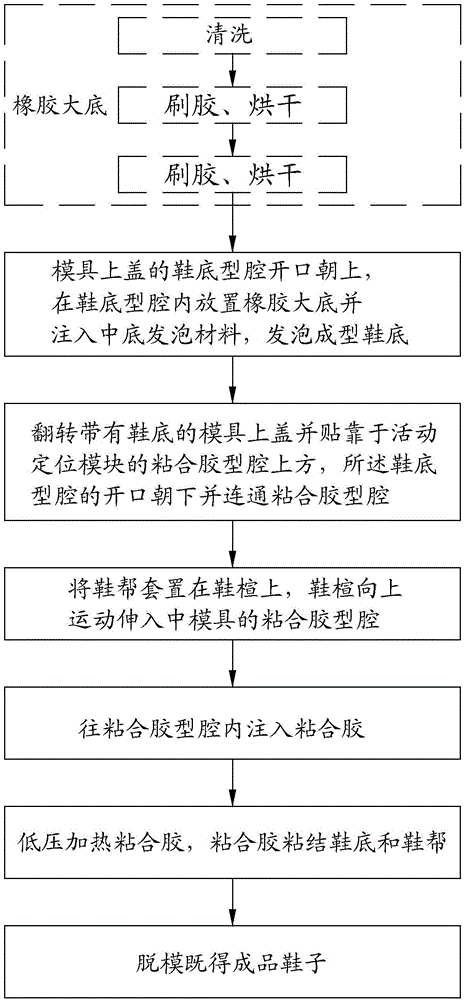

[0035] see Figure 1 to Figure 5 , the present invention discloses a shoemaking process for integrally formed shoes, which includes the following steps,

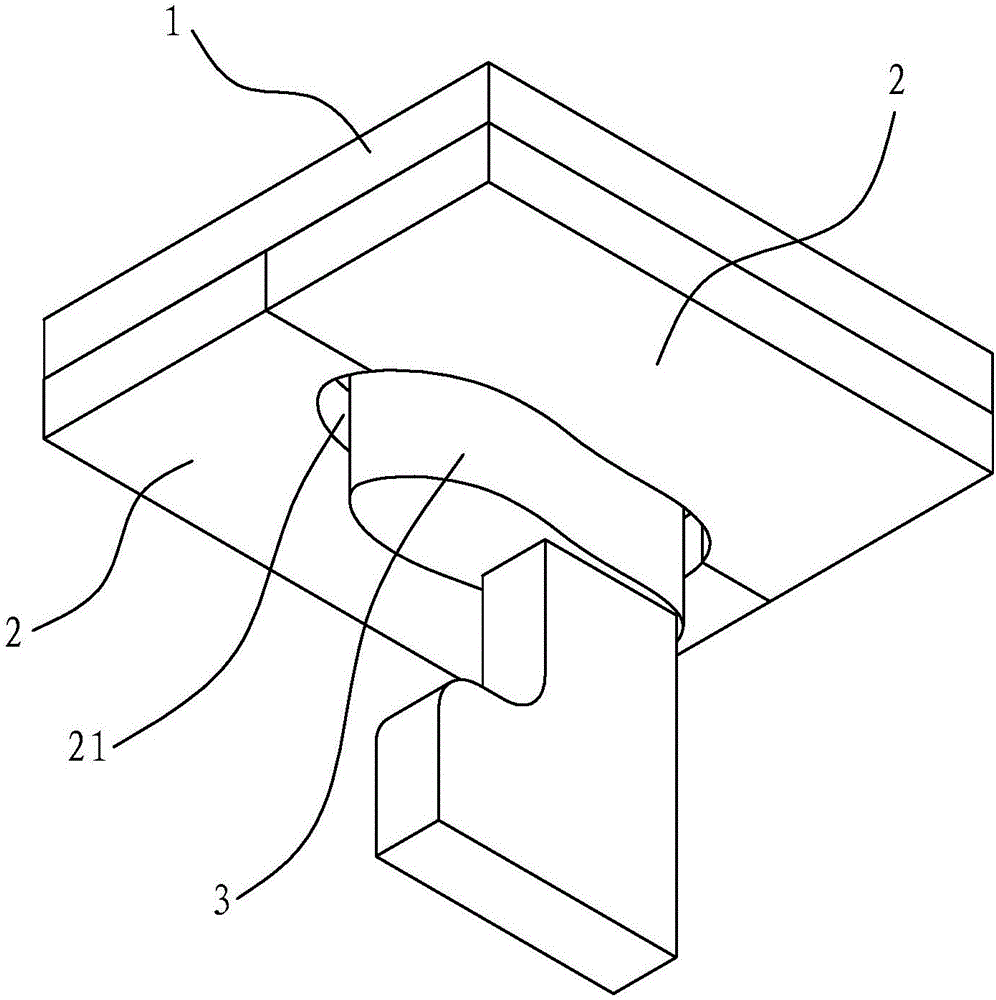

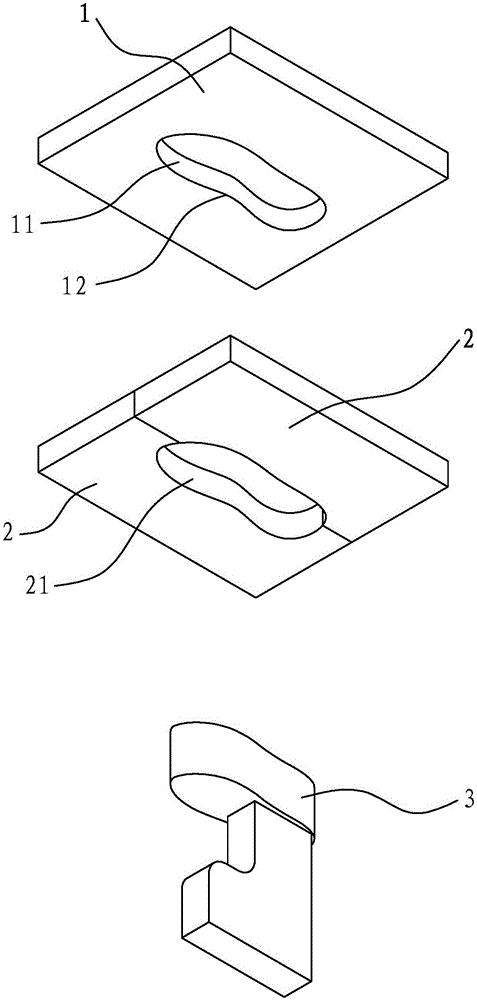

[0036] ① The cavity opening 12 of the sole cavity 11 of the mold upper cover 1 is facing upward, and the rubber outsole 30 is placed in the sole cavity 11, and the midsole foaming material 40 is injected into the cavity above the rubber outsole 30 to form the sole by foaming 10;

[0037] ② Turn over the mold upper cover 1 with the molded sole 10 by 180° and stick it on the top of the movable positioning module 2. The movable positioning module 2 has an adhesive cavity 21 that penetrates up and down, and the cavity opening 12 faces downward and communicates with the mold cavity. Adhesive cavity 21;

[0038] ③ Place the shoe upper 20 on the shoe last 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com