A high-efficiency bearing ring production equipment

A technology for production equipment and bearing rings, applied in the field of bearing production equipment, can solve problems such as easy occurrence of dangerous accidents, easy adhesion of bearing rings and molds, and injuries to workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

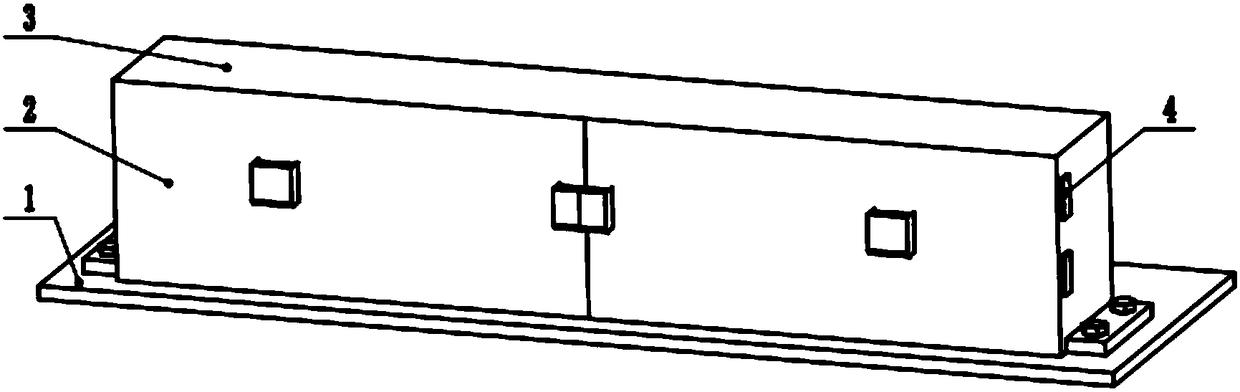

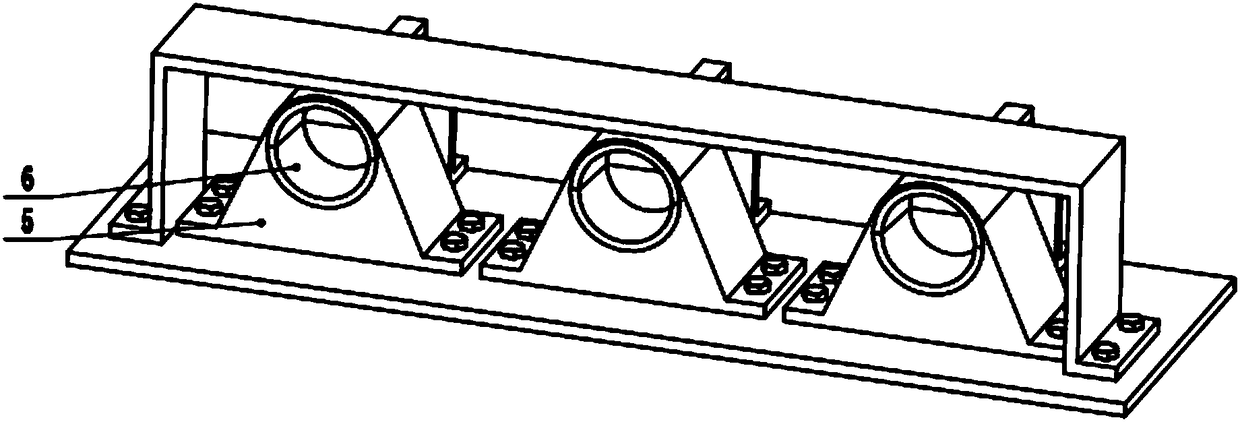

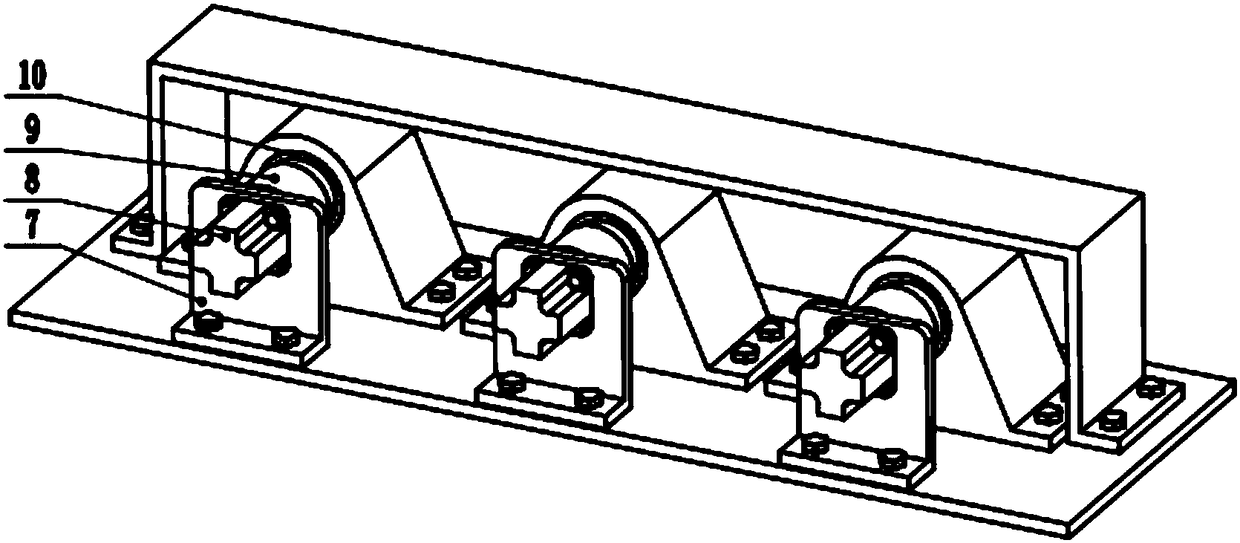

[0021] A high-efficiency bearing ring production equipment is composed of a base plate 1, a door 2, a bracket 3, a hinge 4, a bearing ring seat 5, a mold cavity 6, a motor mounting frame 7, a motor 8, a coupling 9, a bearing 10, and a rotating shaft 11. The spring 12 is composed of a control device. The base plate 1 has a base plate body 101, a bracket mounting hole 102, a bearing ring seat mounting hole 103 and a motor mounting frame mounting hole 104. The door 2 includes a door body 201, Melt injection port one 202 and melt injection port two 203 structures, the bearing ring seat 5 includes a bearing ring seat hole 501, a mold inner cavity limiting hole 502 and a bearing installation hole 503 structure, and the mold inner cavity 6 Including the structure of the shaft installation protrusion 601 and the bearing ring forming cavity 602, the shaft 11 has a mold inner cavity installation hole 1101 and a spring installation hole 1102 structure, the bracket 3 is installed on the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com