Prefabricated hollow wall panel and cast-in-place concrete wall panel mounting node

A technology of hollow wall panels and concrete, applied in the direction of walls, building components, buildings, etc., to achieve the effect of balance, stability and improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

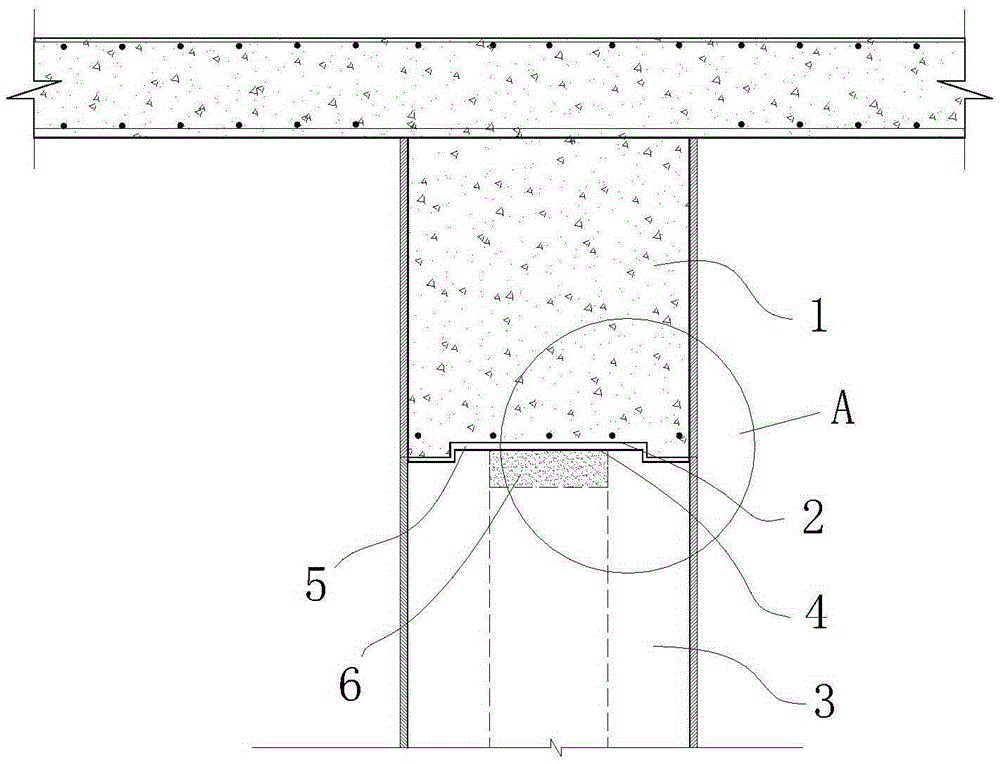

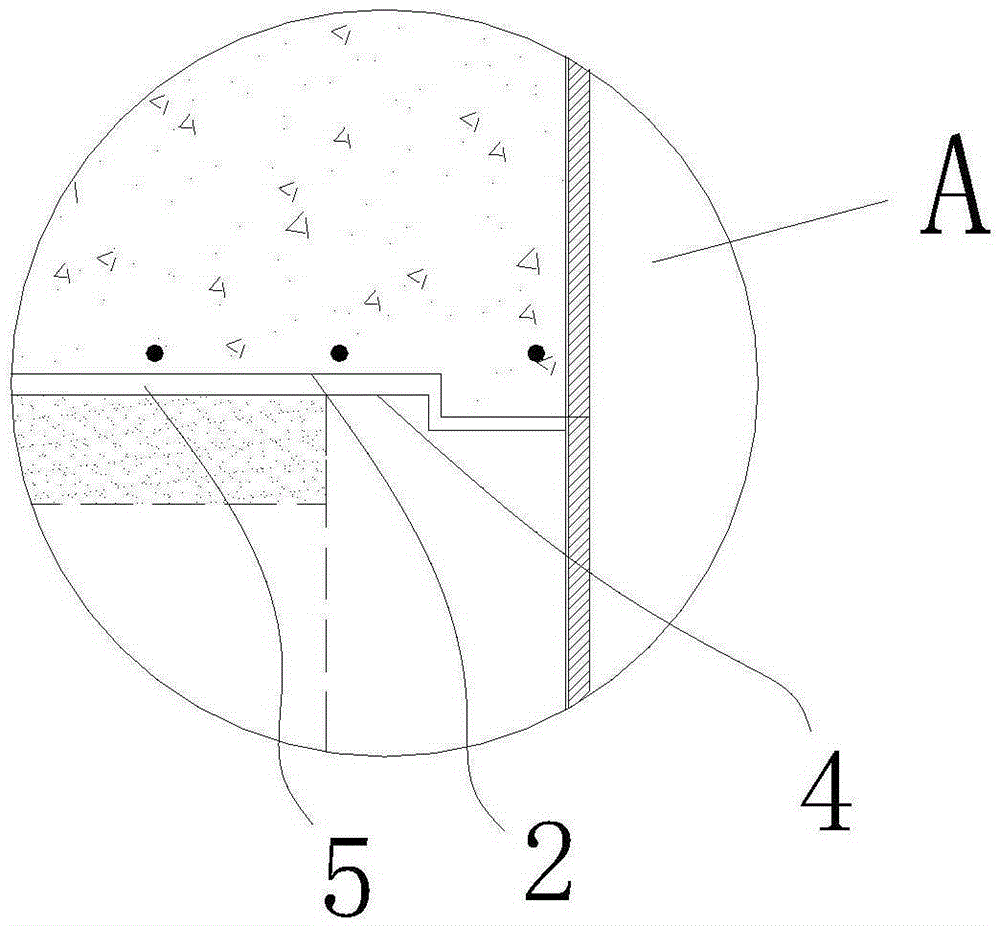

[0021] refer to figure 1 with figure 2 The present invention provides an embodiment of an installation node between a prefabricated hollow wall panel and a cast-in-place concrete wall panel, which is the installation node between a prefabricated hollow wall panel 3 and a cast-in-place concrete beam 1 on an outer wall, and the lower end surface of the cast-in-place concrete beam 1 forms a concave Groove 2, the groove 2 extends along the longitudinal direction of the cast-in-place concrete beam 1, and the groove 2 is recessed 20mm inward from the lower end surface of the cast-in-place concrete beam 1.

[0022] The upper end surface of the prefabricated hollow wall panel 3 of the outer wall forms a raised strip 4 matching the groove 2 on the lower end surface of the cast-in-place concrete beam 1, and the raised strip 4 extends along the longitudinal direction of the prefabricated hollow wall panel 3 of the outer wall. Pressure grouting is performed between the lower end surface...

Embodiment 2

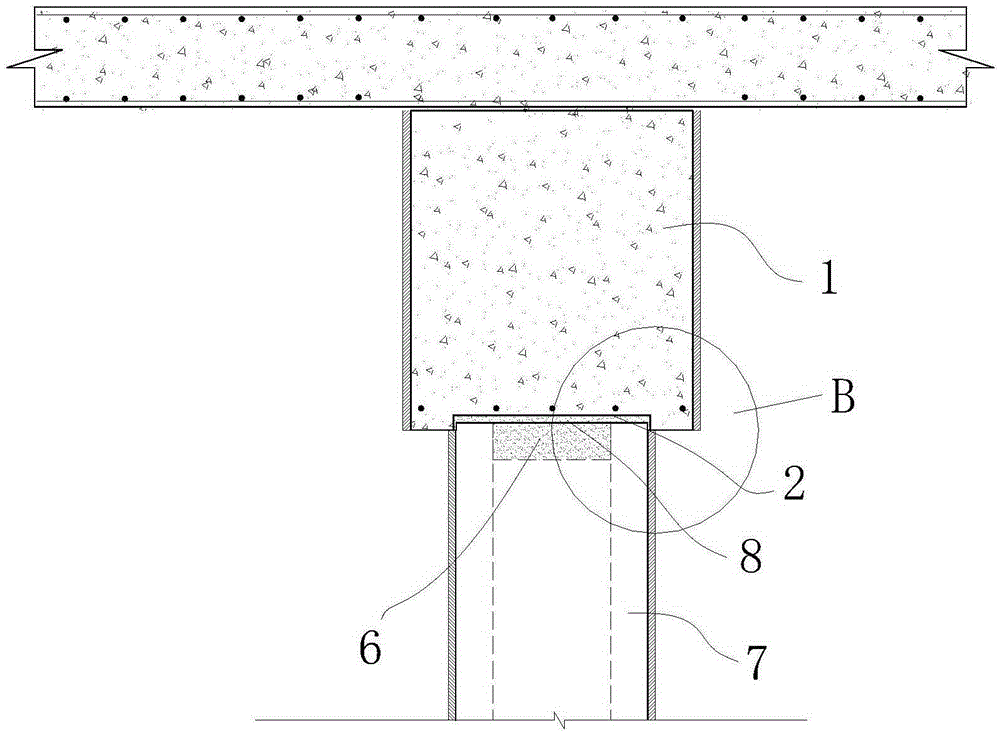

[0025] refer to image 3 with Figure 4 , the present invention provides an embodiment of a prefabricated hollow wall panel and a cast-in-place concrete wall panel installation node, which is an installation node between a prefabricated hollow wall panel 7 and a cast-in-place concrete beam 1 on an interior wall, and the cast-in-place concrete beam 1 in this embodiment Same as Example 1, the upper end surface of the prefabricated hollow wall panel 7 for the inner wall is a plane, and the distance between the two walls of the prefabricated hollow wall panel 7 for the inner wall is slightly smaller than the groove 2 formed by the lower end surface of the cast-in-place concrete beam 1. The distance from the inner side, so that the upper end of the prefabricated hollow wall panel 7 of the inner wall can be embedded in the groove 2, and pressure grouting is performed between the lower end surface of the cast-in-place concrete beam 1 and the upper end surface of the prefabricated hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com