Nailing machine

A nailing machine and stapling technology, applied in the field of nailing machines, can solve the problems of cumbersome and complicated binding process, unfavorable automatic mechanical production, etc., and achieve the effect of improving work efficiency and ensuring work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

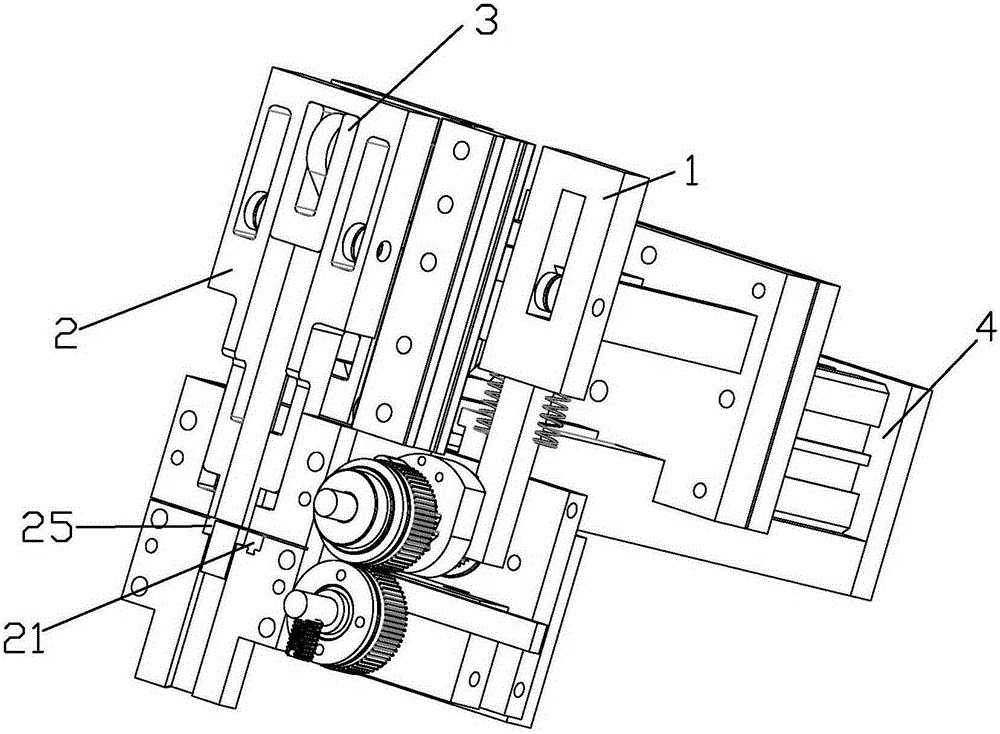

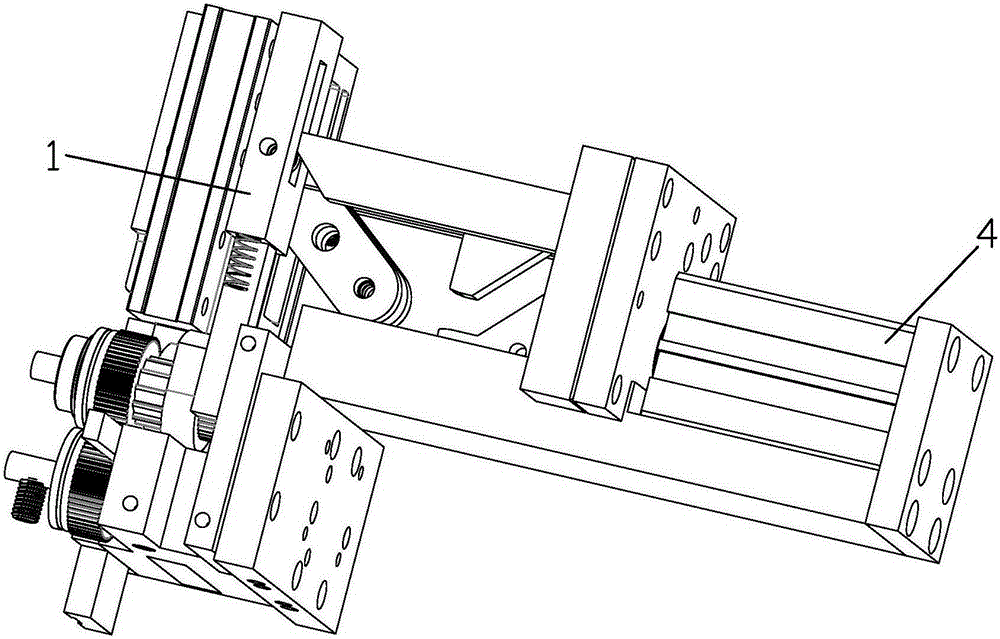

[0026] refer to Figure 1-2 , a nailing machine, comprising: a wire feeding mechanism 1, a shear forming mechanism 2, a nailing mechanism 3, and a driving mechanism 4 for driving the above mechanisms; in this embodiment, the driving mechanism 4 is an air cylinder.

[0027] The wire feeding mechanism 1 sends the metal wire into the shearing and forming mechanism 2 with a fixed length, and the shearing and forming mechanism 2 cuts the metal wire and presses down to form a door-shaped staple; the nailing mechanism 3. Push out the staples to complete the nailing. Therefore, the above-mentioned nailing machine can automatically complete the making and nailing of the staples without manual loading of the staples, which greatly improves the work efficiency.

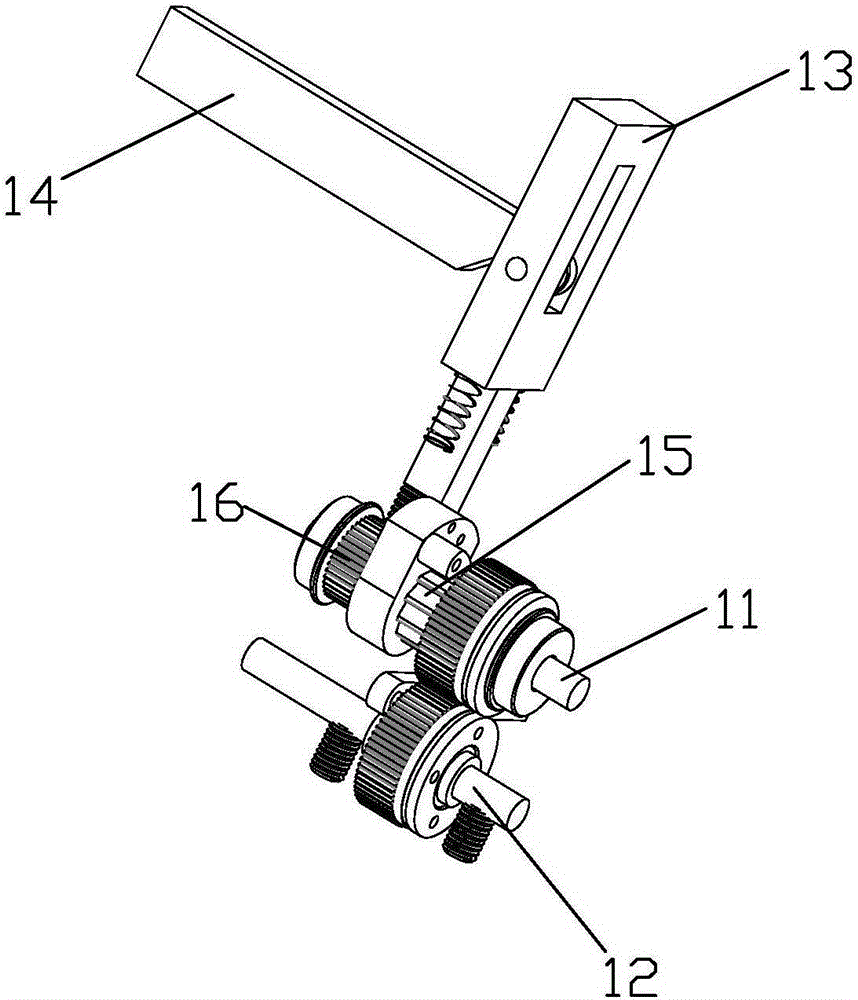

[0028] further reference Figure 3-4 , the wire feeder, 1 includes an upper wire feed whee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap