Construction technology of large U-shaped steel sheet pile

A construction process and technology of steel sheet piles, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of increasing the whole row of steel sheet piles, detenting adjacent steel sheet piles, difficult to adjust in place, etc., and achieve the accuracy of pile driving. The effect of high, saving construction cost and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

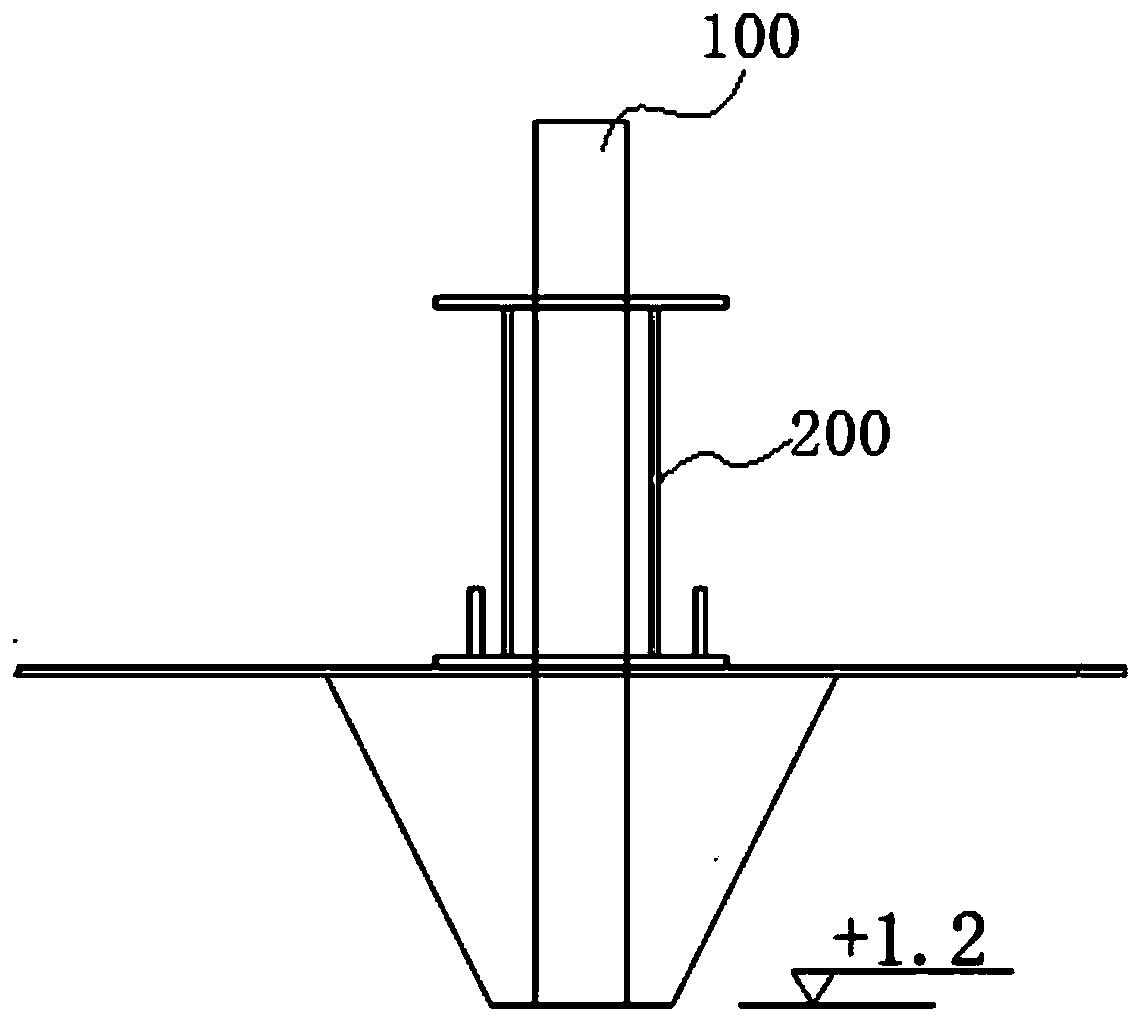

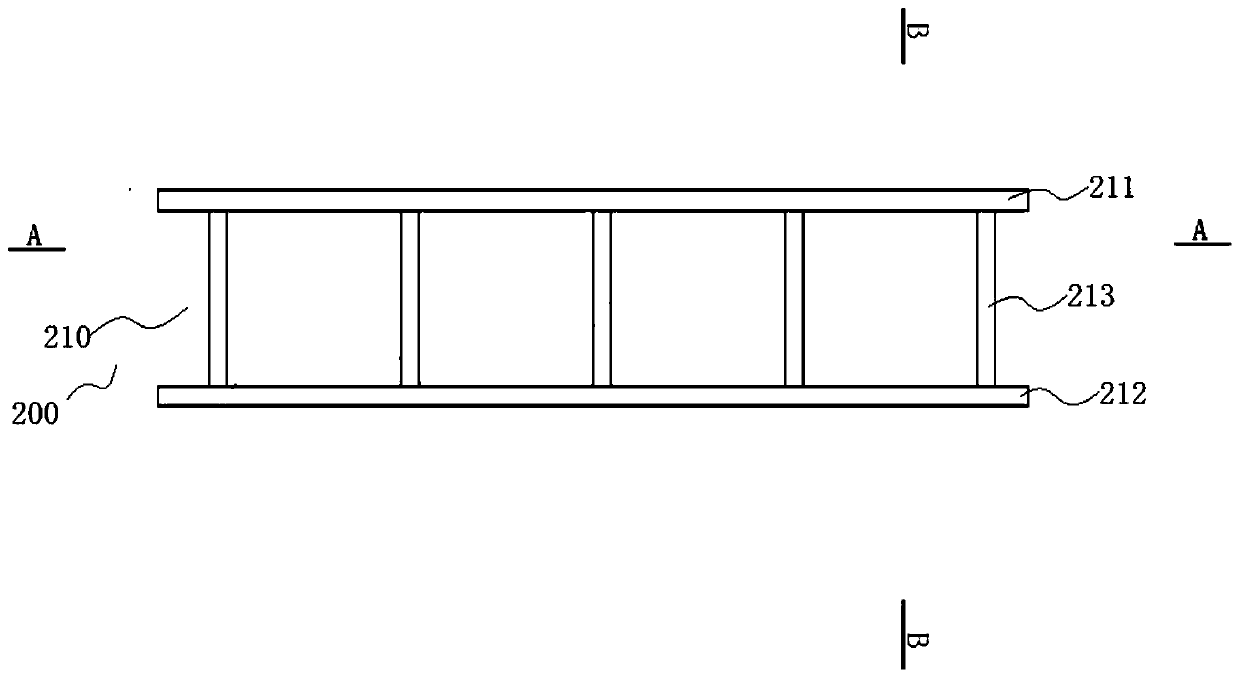

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

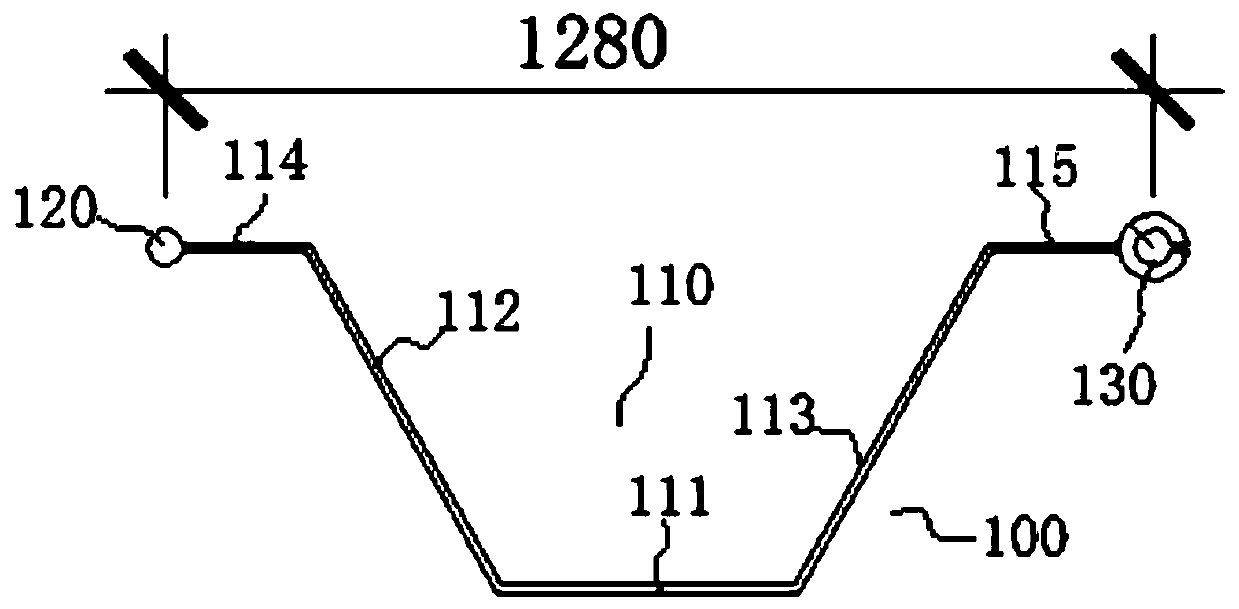

[0033] U-shaped steel sheet piles are often used in projects with high waterproof requirements such as piers, rocks, fixings, breakwaters, diversion dikes, buoys, docks, sluices, water pipes, foundations, anti-seepage walls, and retaining walls. With the continuous improvement of engineering water-stop requirements, U-shaped steel sheet piles have developed from the initial U-shaped grooves to the Larsen steel sheet piles that are commonly used today, and their anti-seepage and water-stop capabilities have been greatly improved.

[0034] However, the lock of the Larsen steel sheet pile is prone to tripping during the pile sinking process, and the water-stop function is still limited. Compared with the Larsen steel sheet pile, the locking U-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com