Mechanical layered liquid sampling device

A liquid sampling and mechanical technology, applied in the direction of sampling devices, etc., can solve the problems of inconvenient sampling of corrosive liquids, inconvenient sampling and analysis of samples of different depths, etc., and achieve the effects of convenient access to samples, convenient operation and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described.

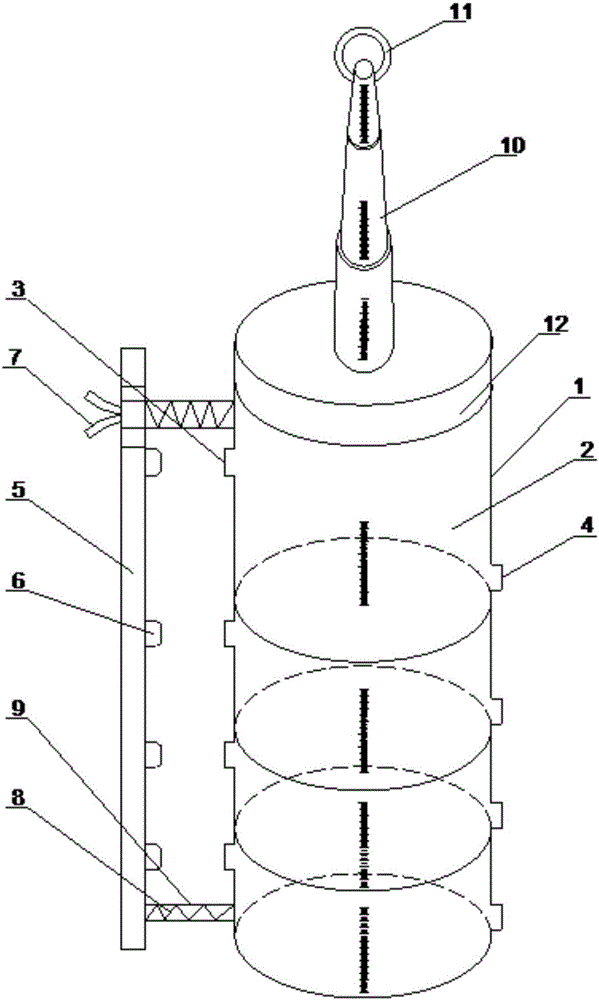

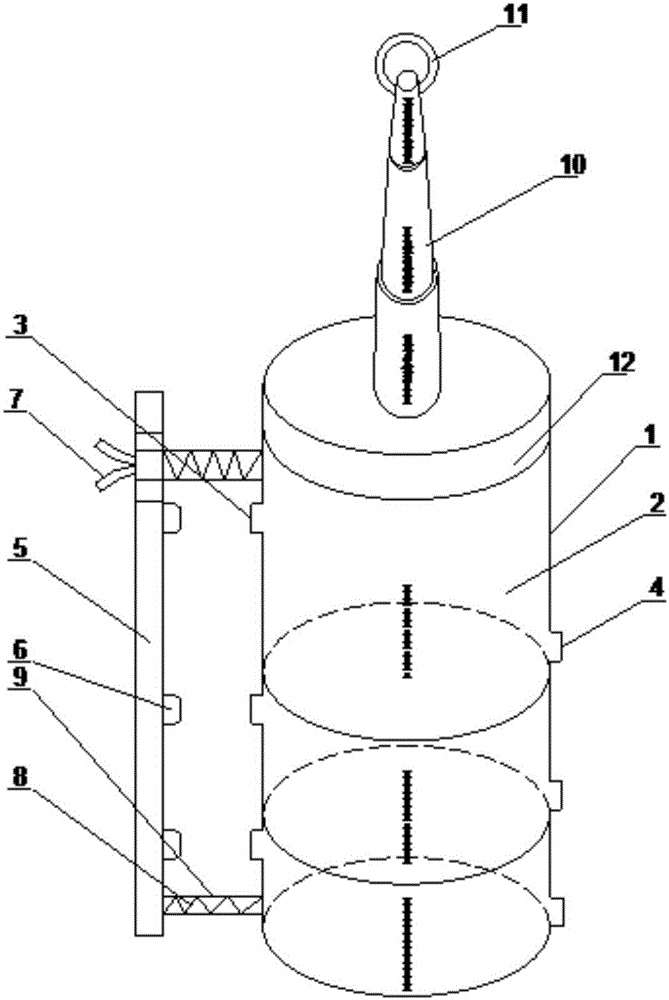

[0015] like Figure 1-2 Shown, a kind of mechanical stratified liquid sampler of the present invention comprises cylinder body 1 and several sample holders 2 ( figure 1 There are 4 samplers, figure 2 There are 3 sample depositors), several sample depositors 2 are evenly arranged along the axial direction of cylinder body 1, separated by partitions to form multiple separate sample storage spaces, and the upper end of each sample depository 2 is equipped with The storage and sampling ports 3 communicated with the internal space of the sample storage 2 , and the lower end of each sample storage 2 is provided with a discharge cleaning port 4 communicating with the internal space of the sample storage 2 .

[0016] A connecting plate 5 is arranged on the outer side of the cylinder 1 along the axial direction. The upper end of the connecting plate 5 is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com