Indoor fidelity sampling, storage and analysis device and method based on deep well sampling

An analysis device and fidelity technology, which is applied in the direction of sampling, measuring devices, and analysis materials, etc., can solve the problems of no sample fidelity, sampling pressure and temperature cannot be maintained, quantitative standards, etc., to ensure the degree of sampling fidelity, Improve sample fidelity and avoid contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

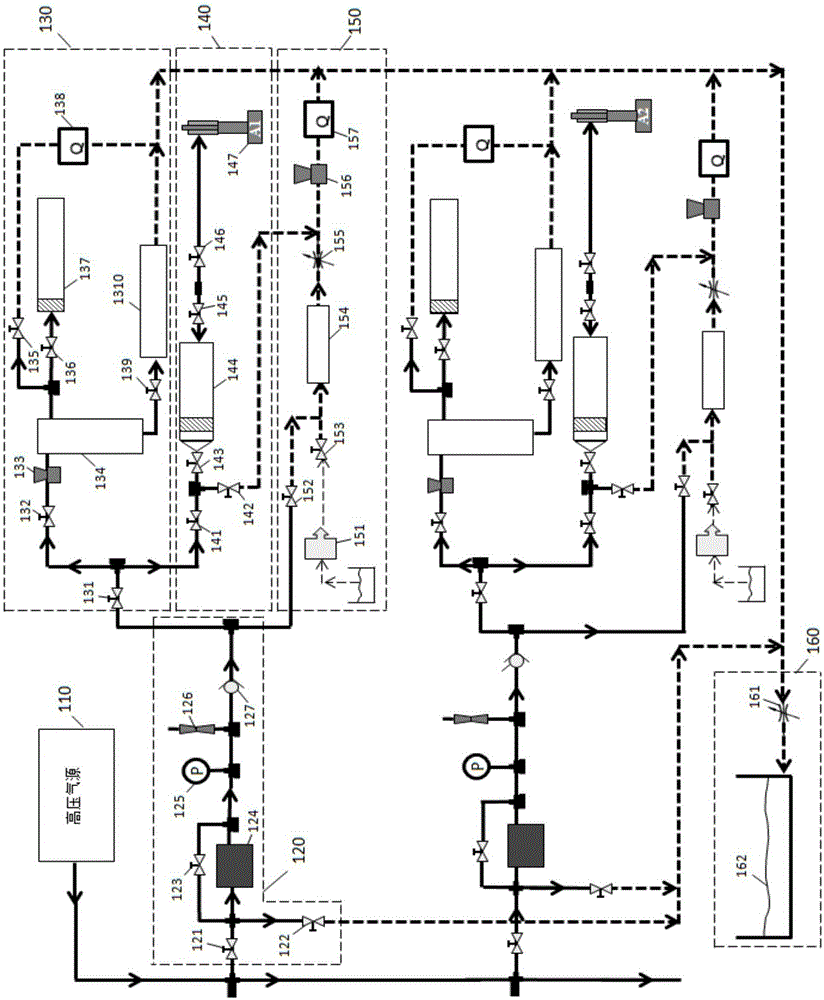

[0042] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

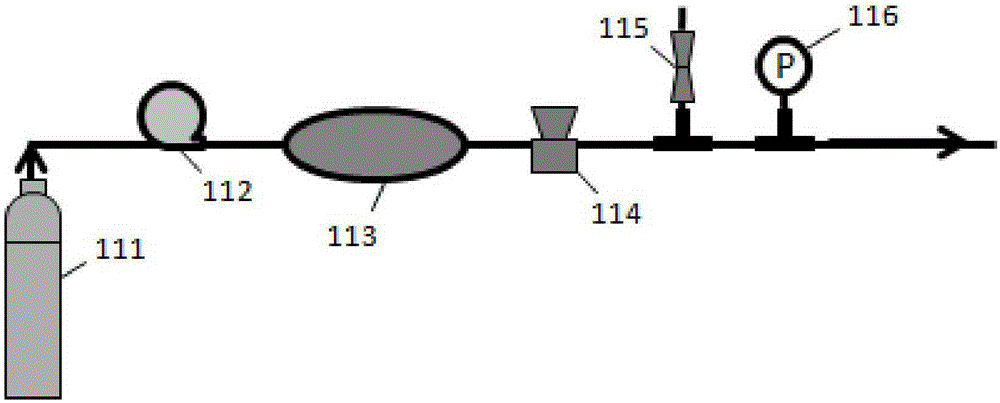

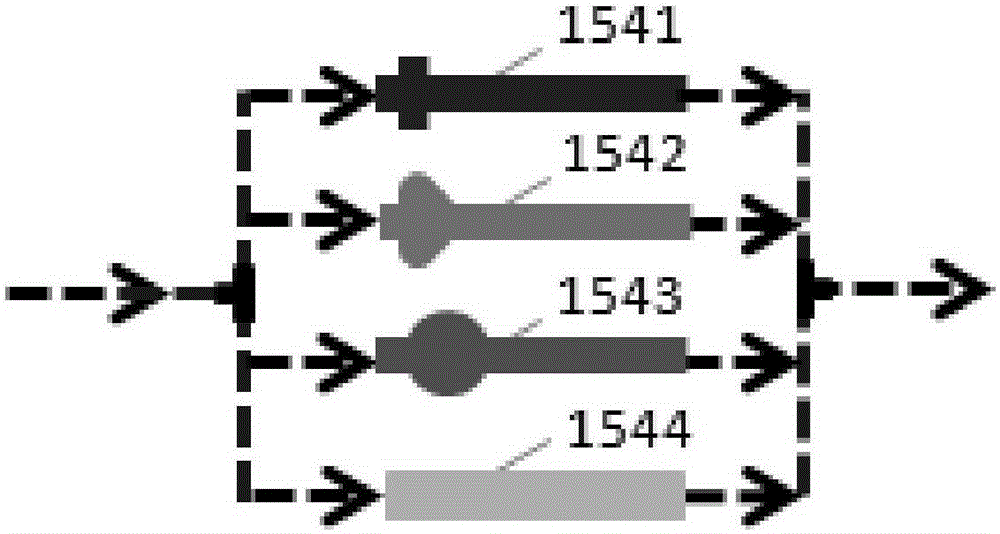

[0043] figure 1 The situation of two-point sampling is described, and the realization of multi-point sampling only needs to add various modules on this basis. One point of the sampling system includes a high-pressure gas source system 110, a fidelity sampling system 120, an instant decompression analysis system 130, a fidelity sample storage system 140, a chemical online analysis system 150, a waste water and gas treatment system 160, and an insulation system; The system includes a fidelity sampling system 120, an instant decompression analysis system 130, a fidelity sample storage system 140, a chemical online analysis system 150 and a heat preservation system. In the two sampling systems, the fidelity sampling system, the real-time decompression analysis system, the fidelity sample storage system, and the chemical online analysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com