A calibration device for high temperature strain calibration from room temperature to 1800°C

A high-temperature strain and calibration device technology, which is applied to measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve problems such as low working temperature and unclear operating temperature range, and achieve the effect of verifying measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

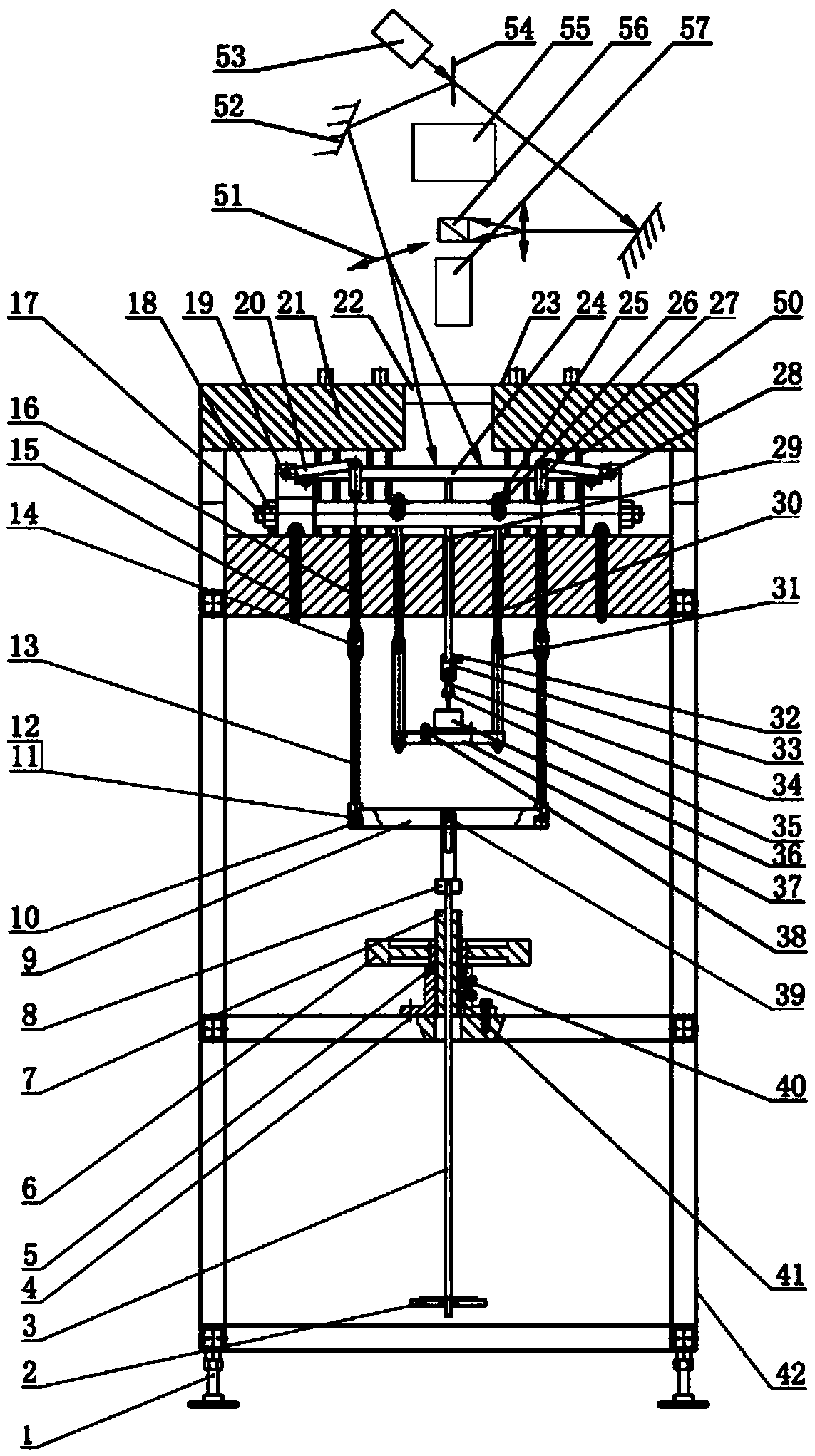

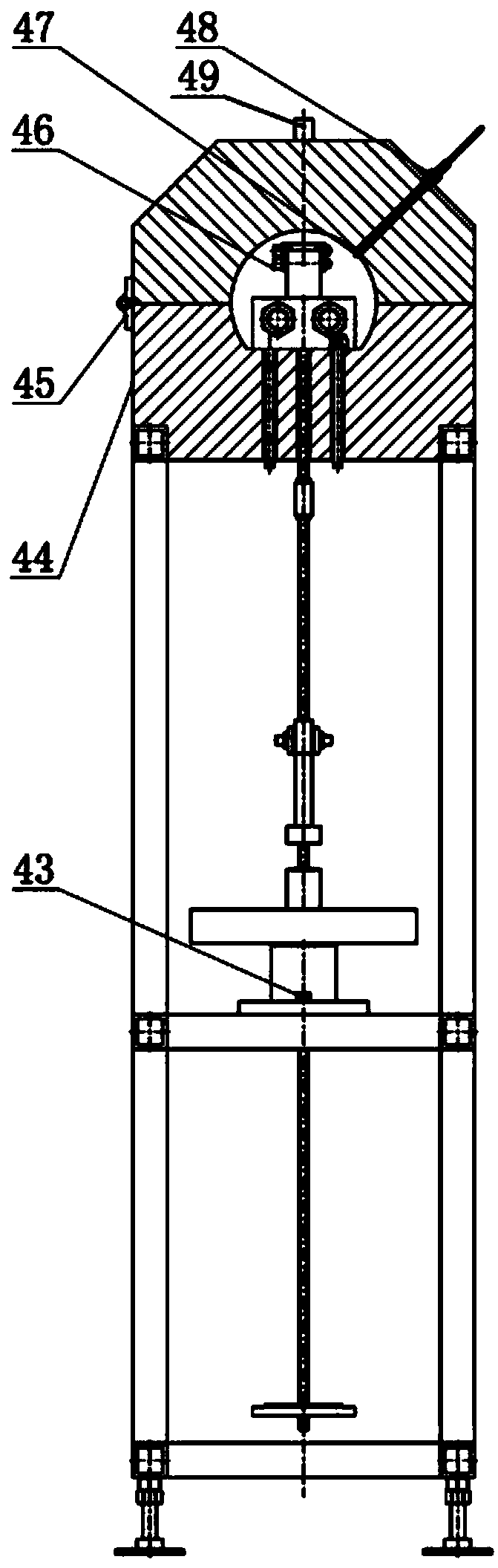

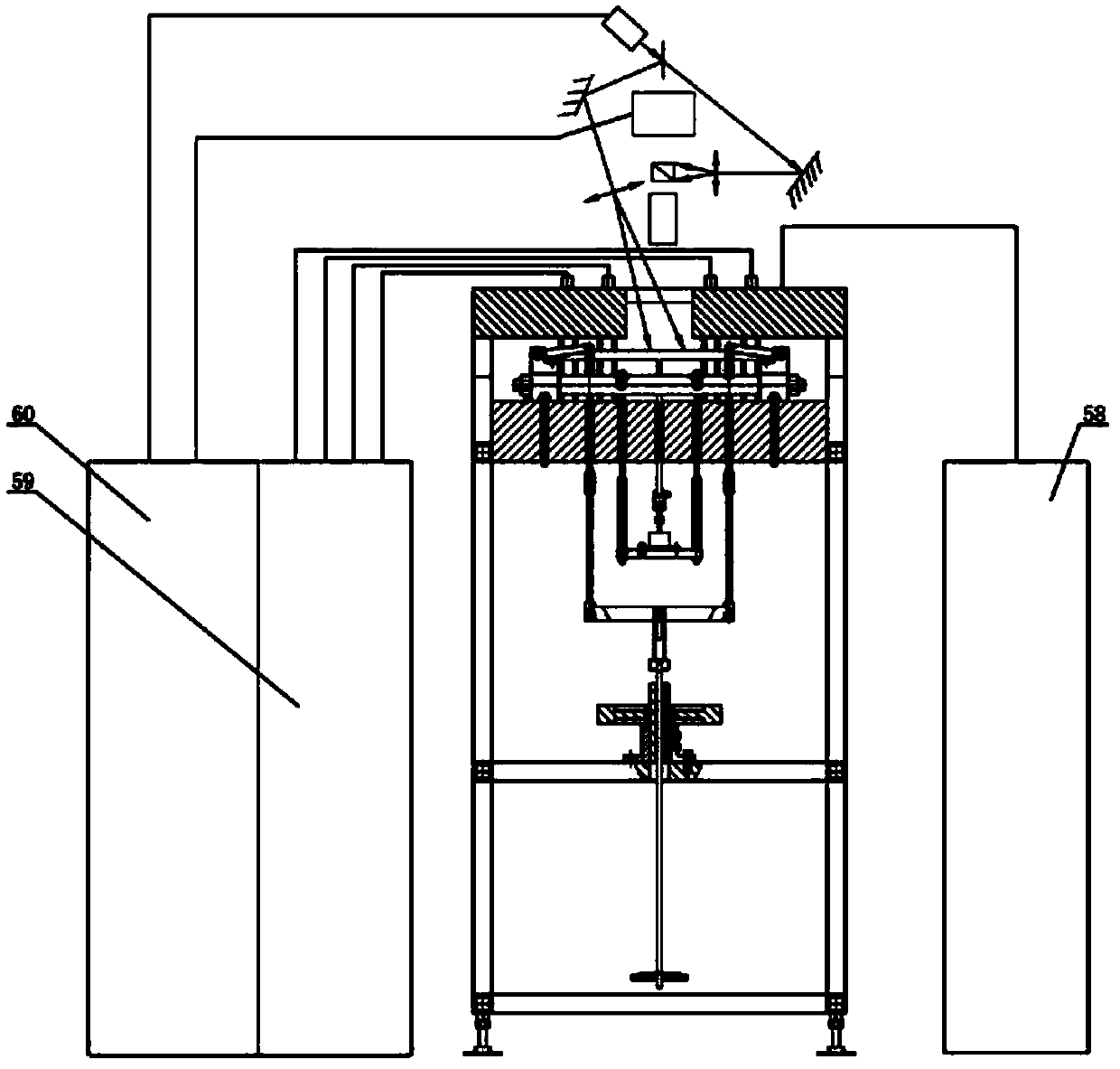

[0031] The invention provides a high-temperature strain calibration device for room temperature to 1800°C, the device includes a high-temperature strain test furnace, a temperature control system and a high-temperature strain test system, wherein the high-temperature strain test furnace consists of a heating and temperature control system, a support system, a loading The system and measurement system are packaged, the temperature control system is installed separately, and the high temperature strain test system is composed of a contact high temperature strain test system and a non-contact high temperature strain test system.

[0032] Such as figure 1 , figure 2 and image 3 As shown, the heating and temperature control system is located in the center...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com