A device and method for detecting anti-counterfeit elements

A technology of anti-counterfeiting components and device pairs, applied in the field of anti-counterfeiting, can solve the problems of universality and accuracy limitation of detection equipment, and achieve the effect of improving universality and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

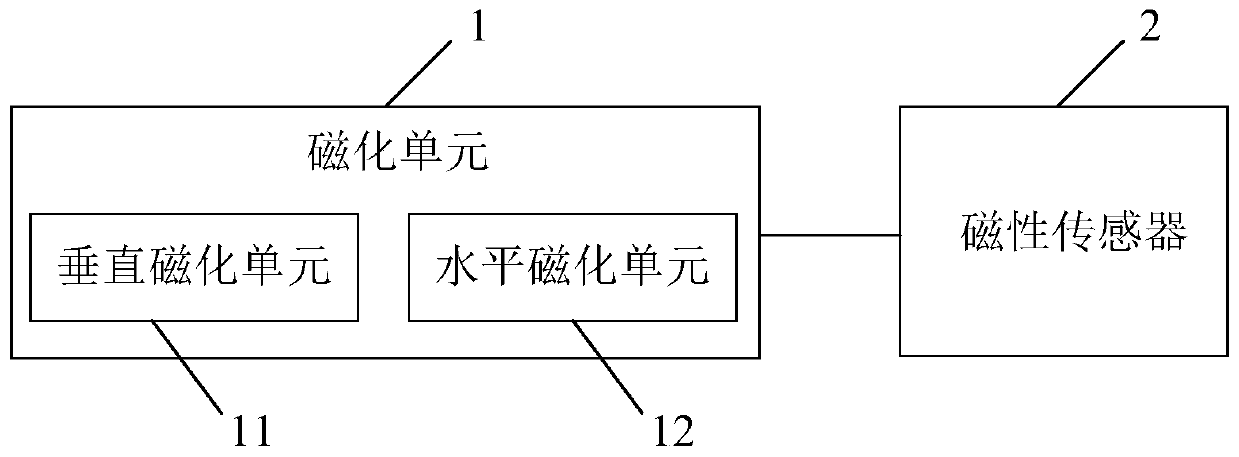

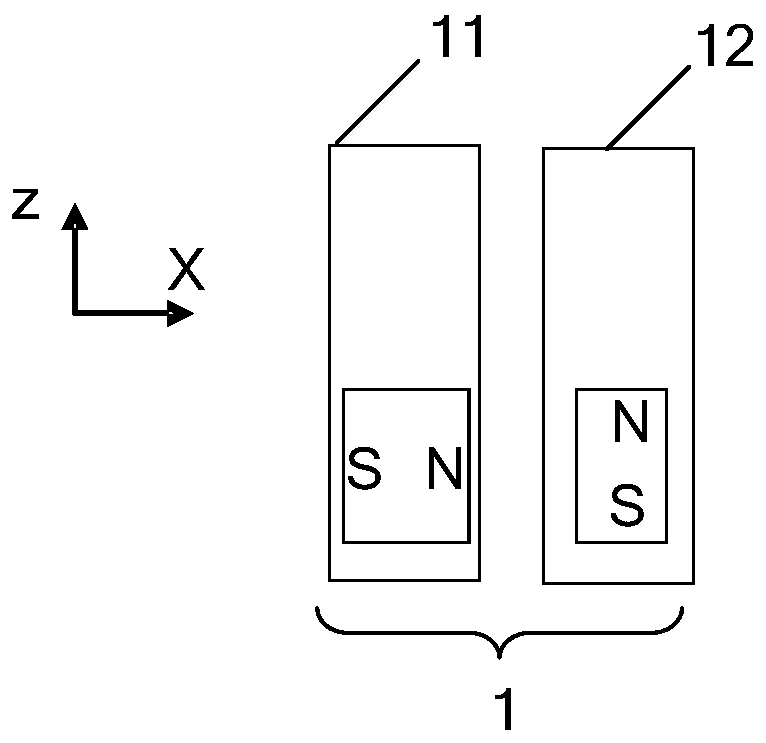

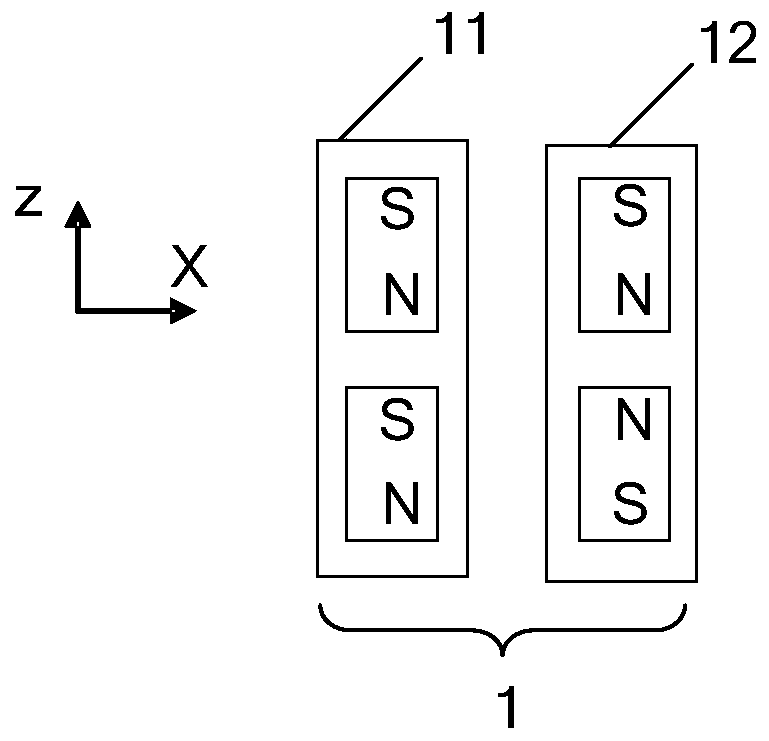

[0034] Such as figure 1 As shown, this embodiment proposes a device for detecting anti-counterfeiting elements, which device includes a magnetization unit 1 and a magnetic sensor 2, and the magnetization unit 1 includes a vertical magnetization unit 11 and a horizontal magnetization unit 12, wherein: the The vertical magnetization unit 11 is used to make the magnetic moment direction of all the magnetic regions in the anti-counterfeiting element be a vertical direction; the horizontal magnetization unit 12 is used to make the magnetic moment direction of all the magnetic regions in the anti-counterfeiting element become a horizontal direction and the magnetic sensor 2 is used to respectively detect the anti-counterfeit element magnetized by the vertical magnetization unit and the anti-counterfeit element magnetized by the horizontal magnetization unit.

[0035] In this embodiment, the magnetic field strength of the vertical magnetization unit 11 and the horizontal magnetizatio...

Embodiment 2

[0041] Based on the same inventive concept as the device for detecting anti-counterfeit elements in embodiment one, this embodiment two provides a method for detecting anti-counterfeit elements using the device, such as Figure 5 As shown, the method includes:

[0042] Step S51 , using a vertical magnetization unit to make the magnetic moments of all the magnetic regions in the anti-counterfeiting element be vertical.

[0043] Such as Figure 6a As shown, taking the anti-counterfeiting element as an example with two magnetic regions whose directions of easy magnetization axes are vertical and one magnetic region whose directions of easy magnetization axes are non-perpendicular directions, the direction of easy magnetization axes shown in the figure is the magnetic The direction of the easy magnetization axis of the region (that is, the region labeled P) is the horizontal direction, but this illustration does not constitute a limitation to the present invention, and the direct...

Embodiment 3

[0053] Based on the same inventive idea as the device for detecting anti-counterfeit elements in embodiment one, this embodiment three also provides a method for detecting anti-counterfeit elements using the device, such as Figure 11 As shown, the method includes:

[0054] Step S111 , using a horizontal magnetization unit to make the directions of magnetic moments of all the magnetic regions in the anti-counterfeiting element be horizontal.

[0055] Step S112, following step S111, using a magnetic sensor to detect the anti-counterfeit element magnetized by the horizontal magnetization unit.

[0056] Step S113 , following step S112 , using a vertical magnetization unit to make the directions of magnetic moments of all the magnetic regions in the anti-counterfeiting element vertical.

[0057] Step S114, using a magnetic sensor to detect the anti-counterfeiting element magnetized by the perpendicular magnetization unit.

[0058] Compared with Embodiment 2, this embodiment chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com