Lacquer brushing tool for glue mixing screw rod

A technology of mixing screw and screw rod, which is applied in the field of painting tooling of rubber mixing screw rod, which can solve the problems of laborious brushing, troublesome cleaning, environmental pollution, etc., and achieve the effect of easy cleaning, not easy to miss brushing, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

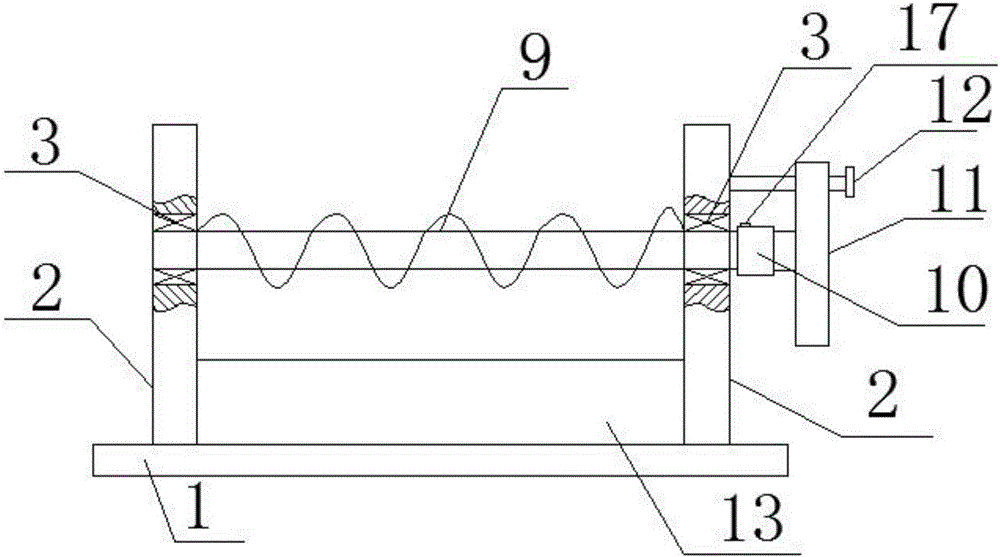

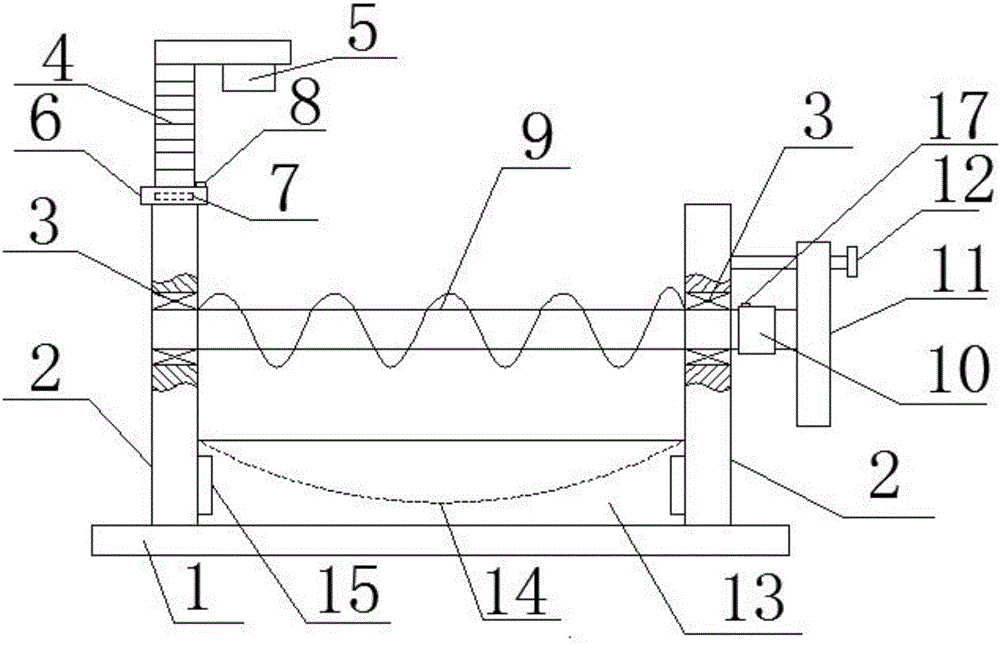

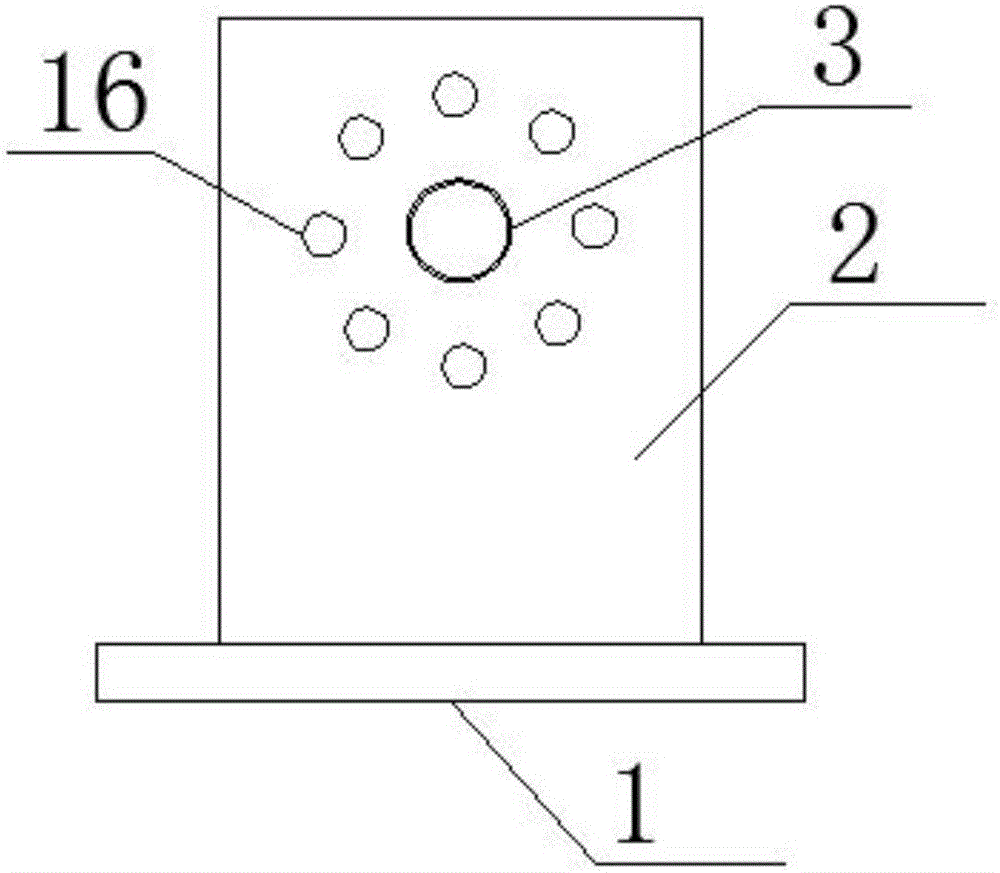

[0019] figure 2 , image 3 and Figure 4 The specific embodiment of the present invention is shown: a paint tooling for rubber mixing screw rods, including a base 1, a connecting cylinder 10 and a handle 11, both ends of the base 1 are provided with support plates 2 upward, and the support plates 2 are provided with bearings 3, both ends of the screw rod 9 are arranged on the bearings 3, the screw rod 9 is rotationally connected with the support plate 2 through the bearing 3, the handle 11 and the screw rod 9 are connected through the connecting cylinder 10, connected One end of the cylinder 10 is connected to the screw rod 9 by a pin 17, and the other end is screwed to the handle 11. The side wall of one of the support plates 2 is provided with several positioning holes 16 arranged in a ring around the center of the bearing 3. The handle 11 is provided with a positioning pin 12 matching with the positioning hole 16 , and the base 1 is provided with a collecting groove 13 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com