Method of using one hardware to realize thermosensitive printer driving

A technology for hardware timers and thermal printers, applied in printing devices, printing, etc., can solve the problems of occupying the internal space of the POS machine and increasing the volume of the POS machine, and achieve the effects of improving utilization rate, good real-time response effect, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

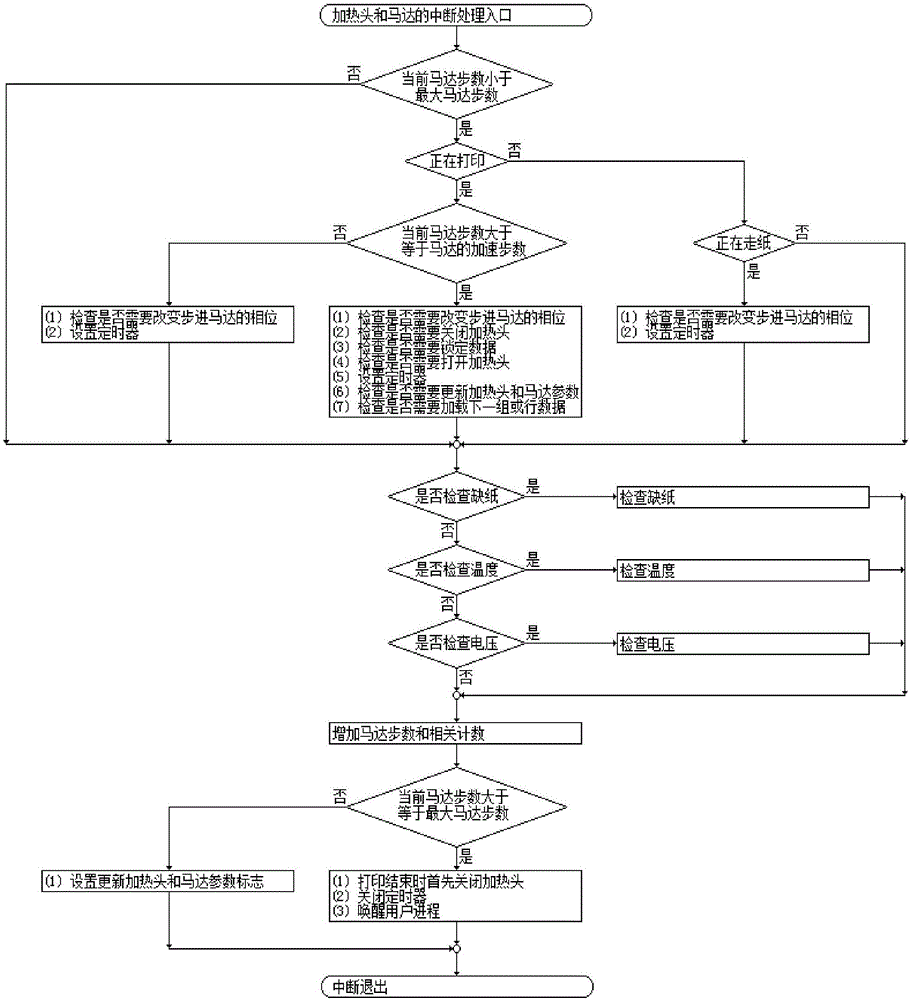

[0026] In this embodiment, only one hardware timer is used to realize the method for driving a thermal printer, the method is implemented based on an interrupt processing program installed in the hardware timer, and the hardware timer is respectively connected to the paper feed motor and the heating head;

[0027] The interrupt processing program is specifically implemented according to the following steps: when printing each new dot line data, calculate the heating time T and the phase change time t of the paper feed motor required to print the new dot line, and at the same time, obtain the phase change of the paper feed motor time t 0 , from t 0 Start to split the overall time required to print a new dot row into two time periods: the phase change time t of the paper feed motor and the heating time T; from t 0 At the beginning, drive the paper feed motor to the specified position, and the time period for the paper feed motor to travel is less than or equal to t; from the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com