Automatic transposition device

An automatic, limit structure technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of labor intensity, difficult production requirements, time-consuming and labor-intensive, and achieve simple structure, simple and convenient operation, and excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

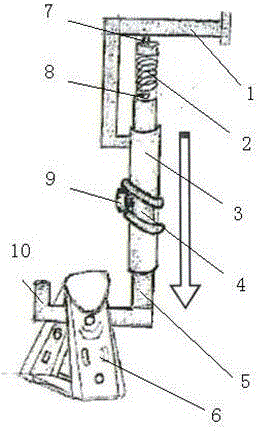

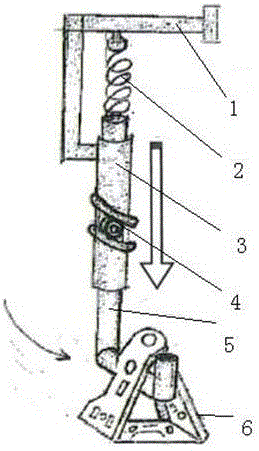

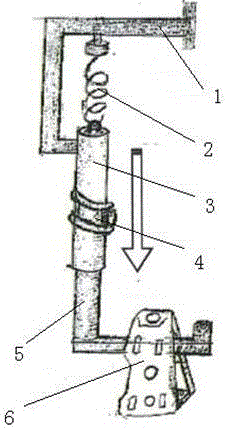

[0010] The structure diagram of the present invention is as figure 1 , 2 , 3, the automatic indexing device of the present invention includes a support frame 1, a spring 2, a support rod 3, a spiral groove 4, and a connecting rod 5, wherein the support rod 3 is fixed on the support frame 1, and the connecting rod 5 is inserted In the hollow cavity provided by the supporting rod 3, the supporting rod 3 is provided with a spiral groove 4, and the upper end of the connecting rod 5 is connected with the supporting frame 1 through the spring 2, and the middle part of the connecting rod 5 is connected with the supporting rod 3 through the connecting pin 9 , and the end of the connecting pin 9 is placed on the helical groove 4 provided by the support rod 3, and the lower end of the connecting rod 5 is hung with the workpiece 6.

[0011] In this embodiment, the upper end of the spring 2 is connected to the support frame 1 through the first adjustable bolt 7 , and the lower end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com