Assembly line with counter

A technology of assembly line and measuring instrument, which is applied in the field of assembly line, can solve the problems of falling off of goods, inability to measure the transport volume of goods, and inability to turn corners in time, so as to achieve the effect of preventing goods from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

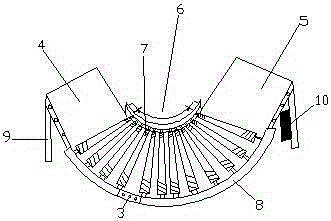

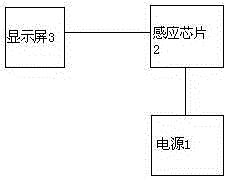

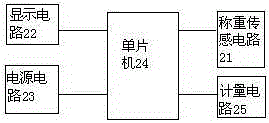

[0017] Such as figure 1 As shown, the assembly line with gauges includes two straight rails (4) and (5) arranged vertically, and it is characterized in that: the assembly line with gauges also includes a bend connecting the two straight rails Bending rail (6), the bending rail includes several rollers (7) arranged in a fan shape and baffles (8) arranged at both ends of several rollers, and a display screen (3) is arranged on the outside of the baffle ), the display screen (3) is connected to the sensing chip (2) and the power supply (1) respectively.

[0018] The feature is that: the diameter of one end of each of the rollers is smaller than the diameter of the other end, so that the plurality of rollers are arranged in a fan shape.

[0019] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com