Marine dedusting shutter

A technology of louvers and louvers, which is applied in ship windows, ship construction, and dispersed particle filtration, etc. It can solve the problems of filter blockage, inconvenient operation of placer transport ships, etc., and achieve the effect of effectively maintaining air permeability and large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

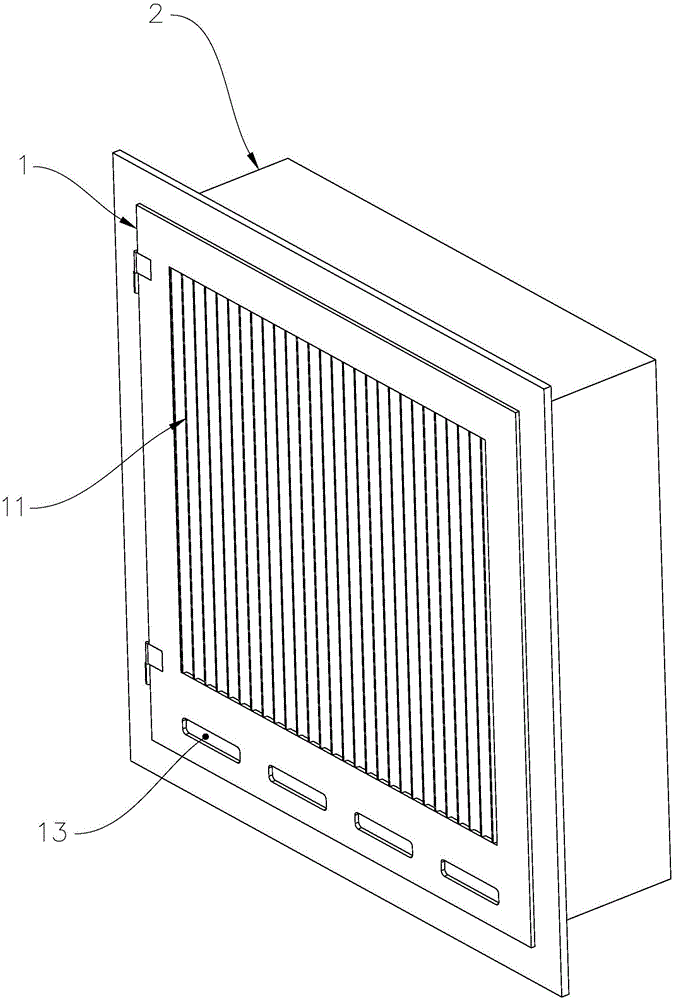

[0032] see figure 1 , figure 1 It is a structural diagram of the first state of the embodiment of the marine dust-removing louver of the present invention. The marine dust removal louvers are installed on the placer transport ship, so the marine dust removal shutters provided by the present invention are designed for dust prevention and ventilation for the sand and dust generated by the humid air at sea, sea water and transported placer materials. The marine dust-removing louver includes a rectangular frame 2 and a louver 2 covering the front side of the rectangular frame 2 . The louver 2 is provided with a plurality of elongated blades 11 , and elongated air vents are formed between adjacent blades 11 .

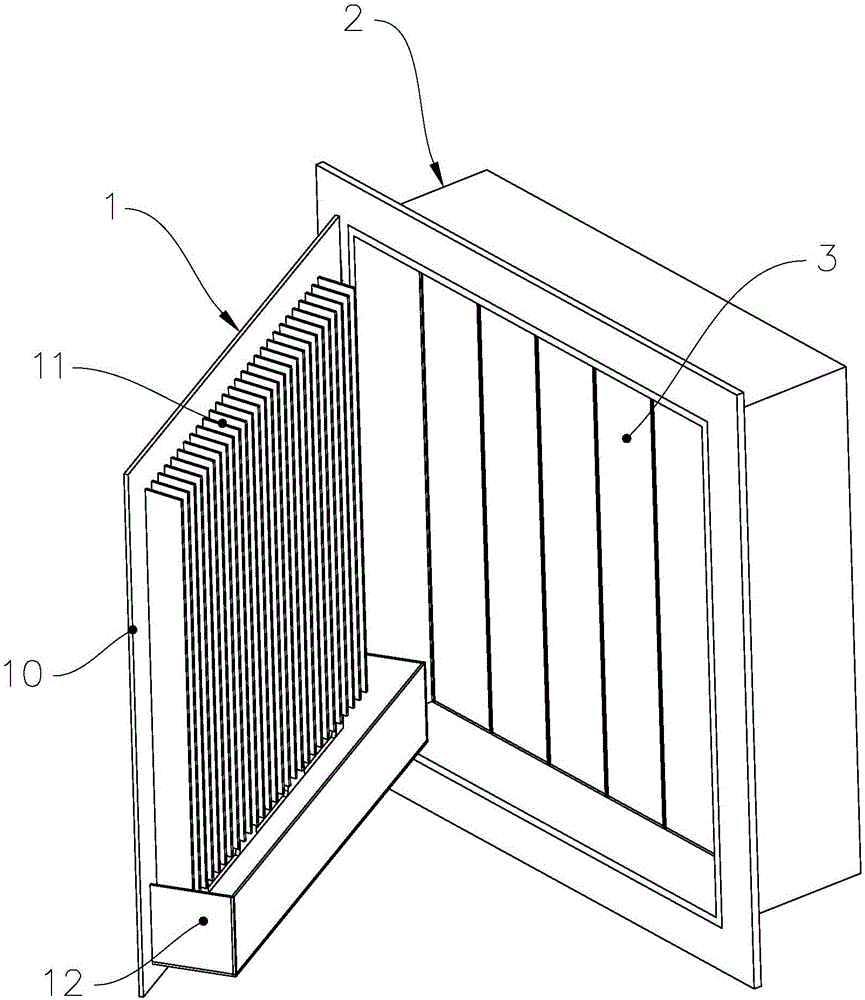

[0033] see figure 2 , figure 2 It is a structural diagram of the second state of the embodiment of the marine dust-removing louver of the present invention. The louver 1 and the rectangular frame 2 are hinged, so the louver 1 can be opened sideways relative to the rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com