Automatic coupling type turning plate wind collecting assembly and device

An automatic coupling, plate type technology, applied in the direction of engines, wind power generation, wind turbines, etc., can solve the problems of backward development of vertical axis wind turbines, little power output, limited application scope, etc., to achieve automatic coupling sensitive, driving force. The effect of large and small wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

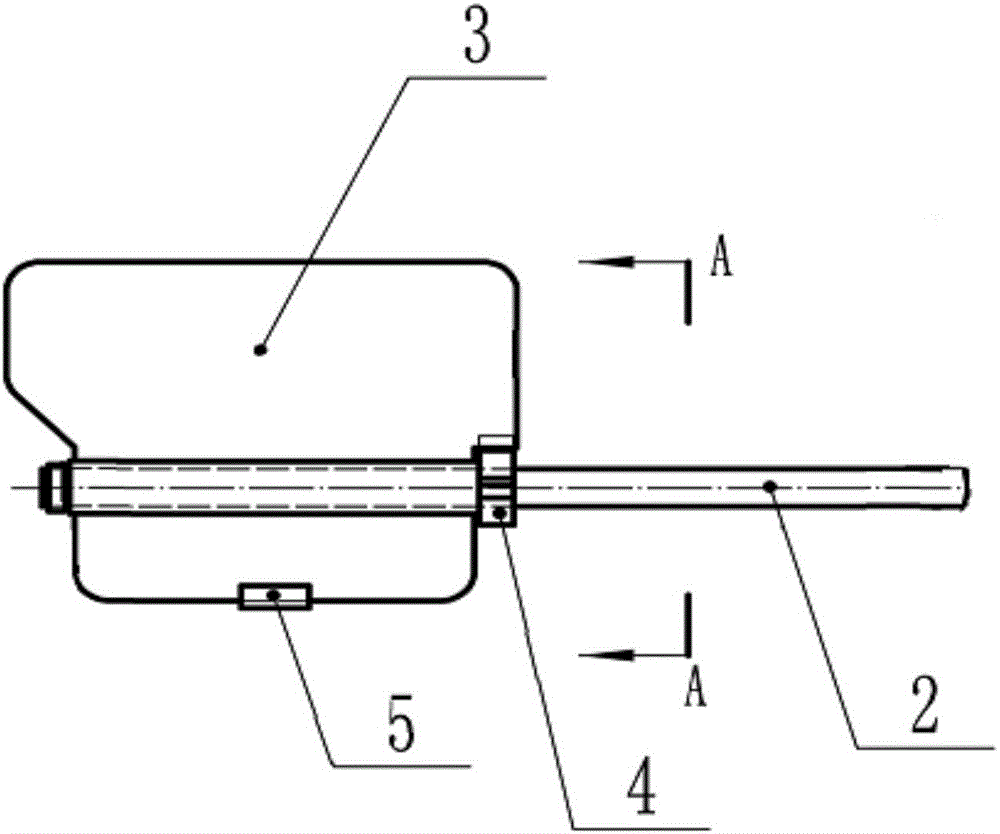

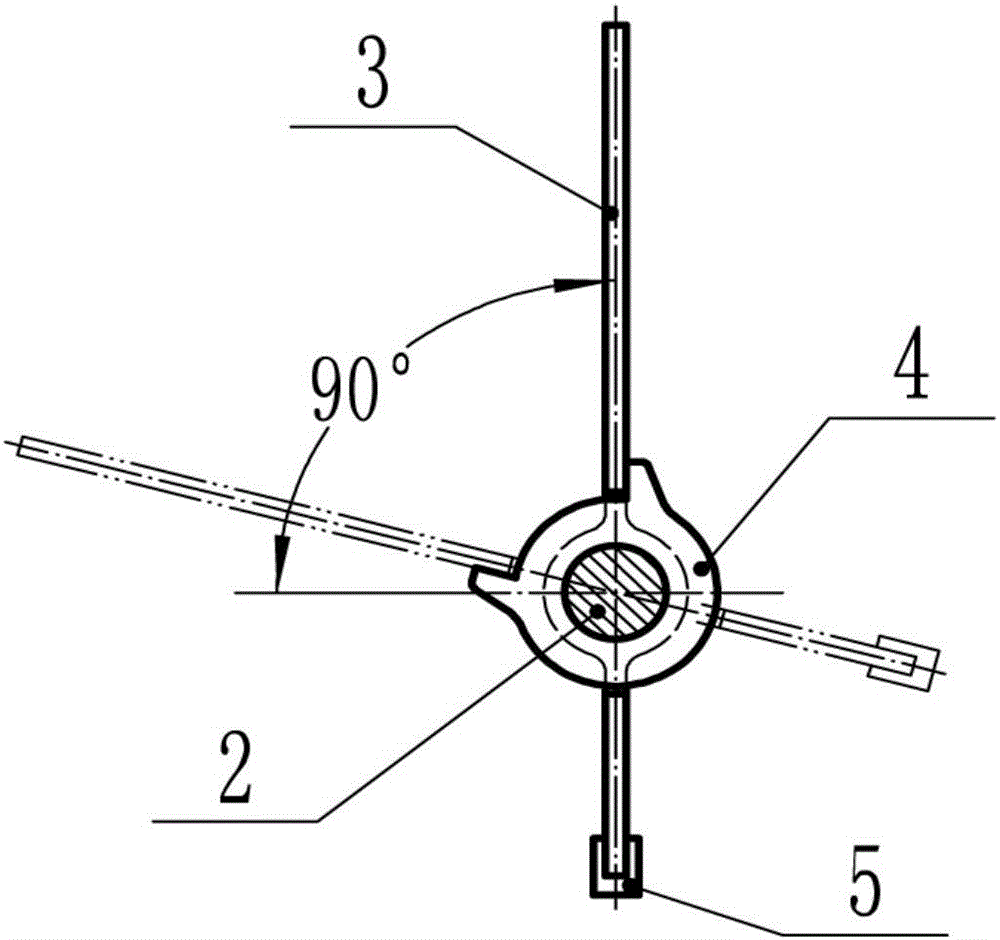

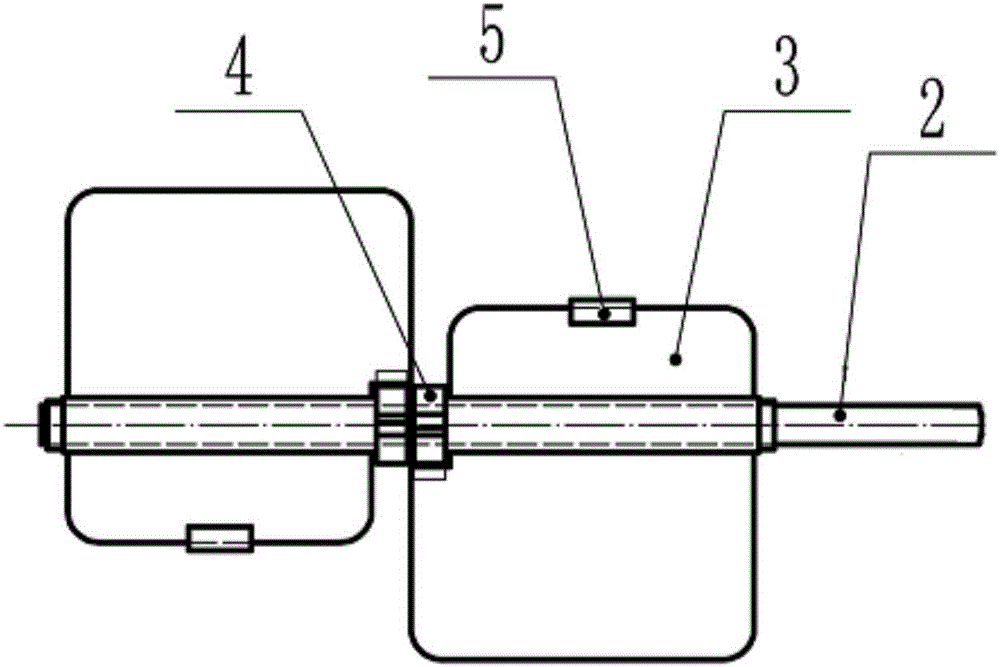

[0023] In this embodiment, an automatic coupling flip-type wind collection assembly includes a fixed rod 2, a plate-shaped blade 3 that is rotatably connected to the fixed rod 2, and a blade fixed on the fixed rod 2 for limiting the flip angle of the plate-shaped blade. Limiting device 4; the rotation axis of the plate-shaped blade 3 is coaxial with the fixed rod 2 and the center of gravity of the plate-shaped blade 3 is located on the rotation axis.

[0024] The plate-shaped blade 3 is a flat plate structure, and the plate-shaped blade 3 is divided into a first blade and a second blade relative to the axis of rotation; the area of the first blade is larger than that of the second blade; the second blade is fixed A counterweight 5 is connected; the working surface of the plate-shaped blade 3 has grooves;

[0025] The blade is a plate structure, no matter it is in a vertical or tilted state, the projected area of its side is very small, so when the blade rotates to the side...

Embodiment 2

[0032] Based on the above-mentioned embodiment, the limiting device 4 in this embodiment is arranged along the same direction as the plate-shaped blade 3; the limiting device 4 includes at least one stopper fixedly connected to the fixed rod 2; The rotation track of the edge of the plate-shaped blade 3 around the rotation axis intersects with the stopper;

[0033] When the wind blows to the working surface of the plate-shaped blade 3, the stopper restricts the rotation of the plate-shaped blade 3 and makes the plate-shaped blade 3 vertical to the wind direction in an upright state;

[0034] When facing the wind (blowing to the direction of the working surface), under the action of wind force, the plate-shaped blade 3 rotates around the fixed rod 2, and when it rotates to be perpendicular to the wind direction, the edge of the plate-shaped blade 3 is in contact with the barrier. Blocks are in contact with each other, the block blocks the plate-shaped blade 3 from rotating, and ...

Embodiment 3

[0042] Such as image 3 As shown, based on the above-mentioned embodiment, several plate-shaped blades 3 are arranged at intervals on the fixed rod 2 in this embodiment; .

[0043] In this embodiment, a plurality of blades and a plurality of limit devices are provided, which increases the wind collection efficiency of the automatic coupling flap type wind collection assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com