Self-locking hydraulic cylinders via elastic elements

A technology of hydraulic cylinders and elastic parts, applied in the field of hydraulic cylinders, to avoid dents, avoid insufficient locking force, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

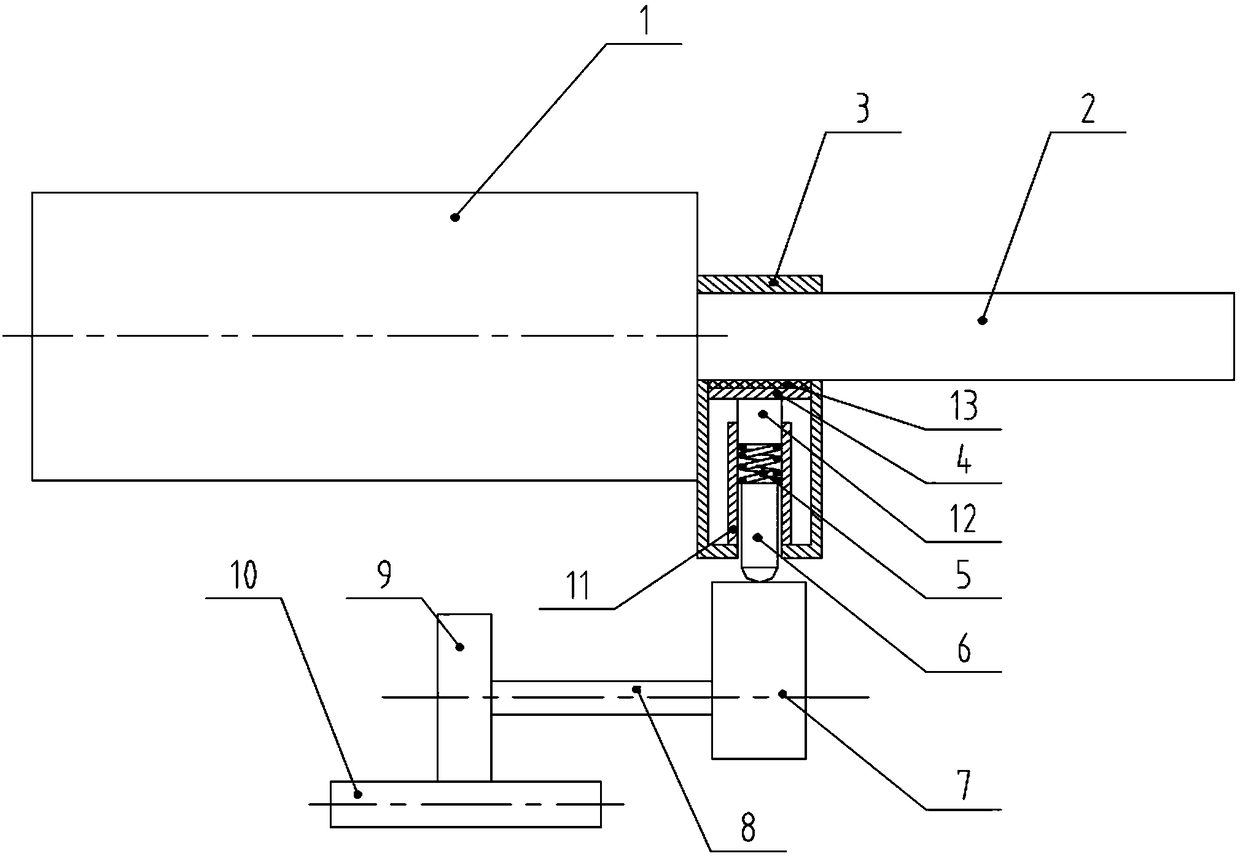

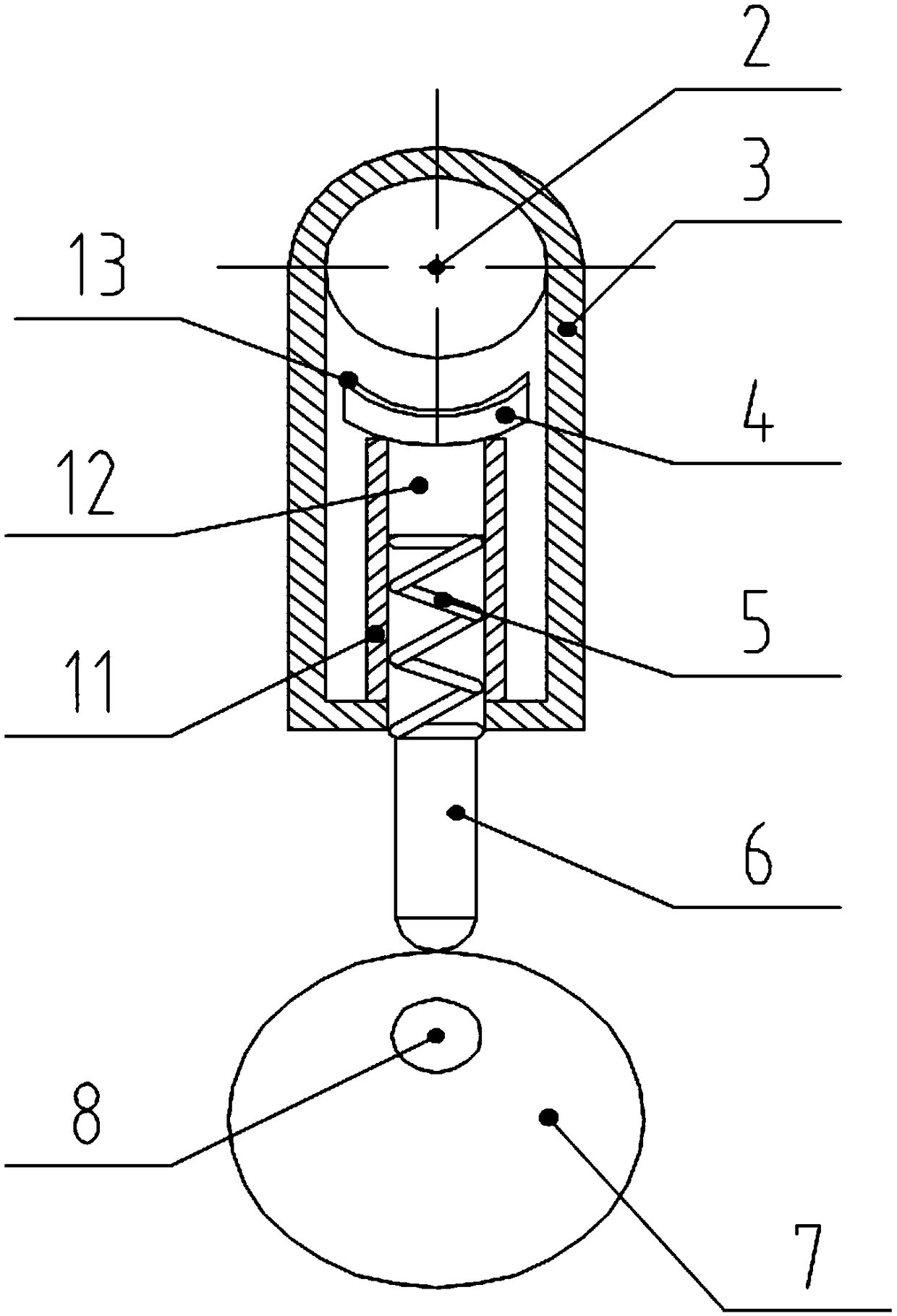

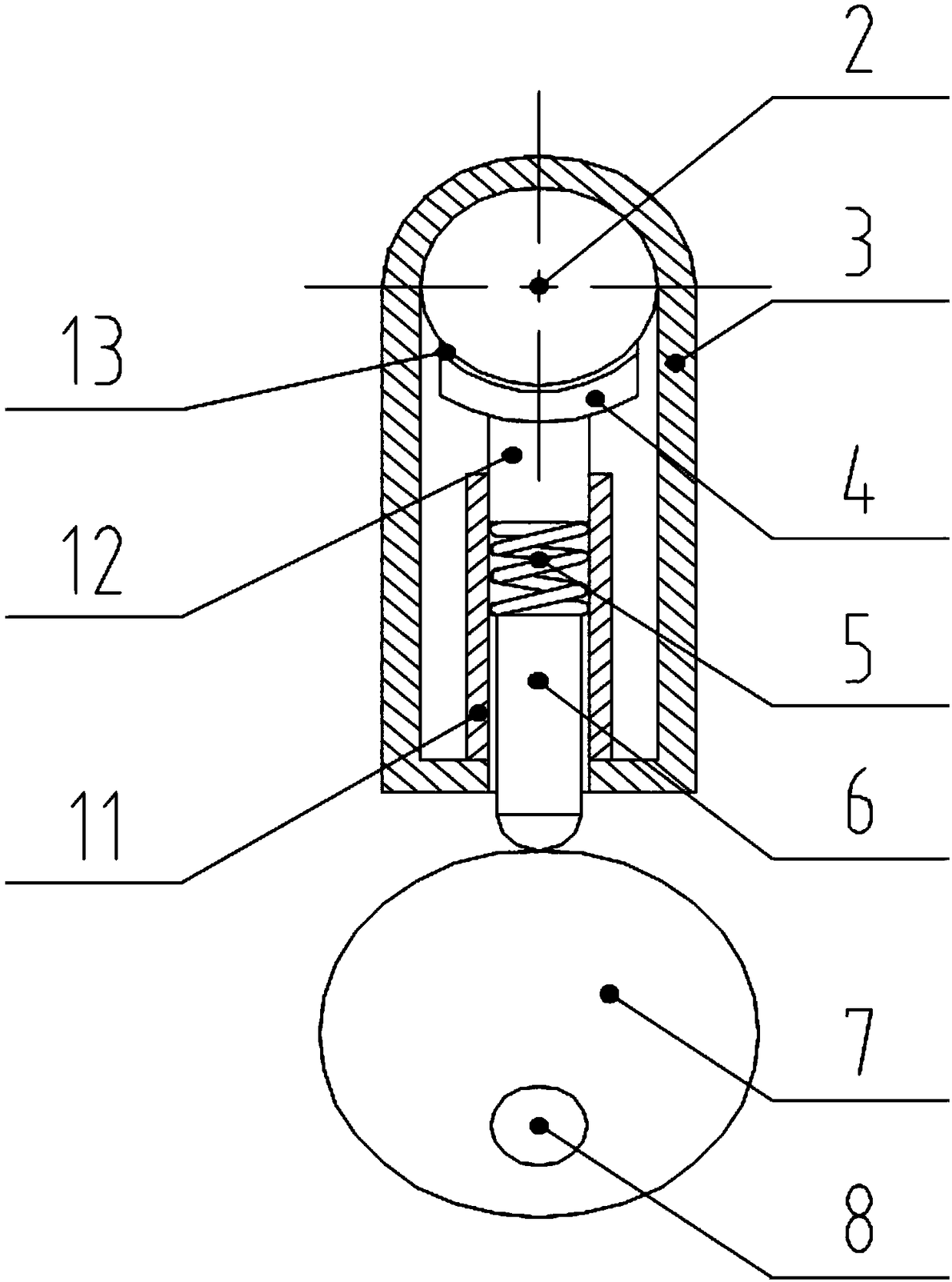

[0023] Such as Figure 1-Figure 3 As shown, the present invention realizes the self-locking hydraulic cylinder through an elastic member, including a hydraulic cylinder body 1 and a locking device arranged on the end face of the hydraulic cylinder body 1, the hydraulic cylinder body 1 is provided with a piston rod 2, and the locking The device includes a positioning frame 3, an eccentric wheel 7, a driving device, and a tightening plate 4, a spring 5, and a guide rod 6 connected in sequence. The positioning frame 3 is installed on the end face of the hydraulic cylinder body 1, and the end face is a piston rod. 2 end faces that can be freely retracted; the piston rod 2 moves through the positioning frame 3, the clamping plate 4, the spring 5 and the guide rod 6 are all located in the positioning frame 3, and the end of the guide rod 6 away from the spring 5 is connected to the eccentric wheel 7 contacts, with the rotation of the eccentric wheel 7, the pressing plate 4 can press...

Embodiment 2

[0029] This embodiment is a further description based on the first embodiment.

[0030] In the structure of the first embodiment, when the center line of the eccentric wheel 7 approaches the axis of the piston rod 2, gravity is mainly used to make the clamping plate 4, the spring 5 and the guide rod 6 fall down. When the axis of the guide rod 6 is not in the vertical direction, the speed of the clamping plate 4 leaving the piston rod 2 is relatively slow, and may even be in a position of contact with the piston rod 2 all the time, which is not convenient for the free expansion and contraction of the piston rod 2.

[0031] At this time, a rotating groove concentric with the eccentric wheel 7 can be set on the side wall of the eccentric wheel 7, the opening size of the rotating groove is smaller than the bottom size of the groove, and a The slide block matched with the cross-sectional size of the rotating groove, along with the rotation of the eccentric wheel 7, the guide rod 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com