Pressurizing device used for mounting complex curved surface heater of spacecraft

An electric heater, manned spacecraft technology, applied in metal processing, metal processing equipment, material gluing and other directions, can solve the problem that the pasted electric heater cannot be pressurized and installed, and achieves high adjustability, tooling and disassembly. Simple, flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

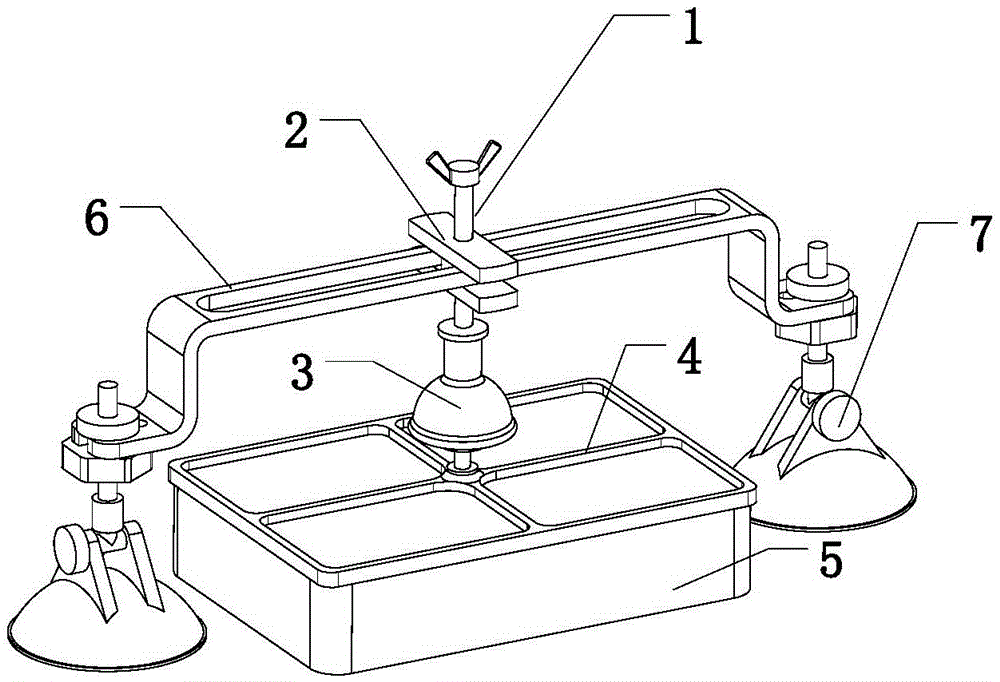

[0016] The following is a further description of the pressurized tooling for installing the electric heater on the bulkhead of a manned spacecraft according to the present invention in conjunction with the accompanying drawings. This description is only exemplary and is not intended to limit the protection scope of the present invention.

[0017] figure 1 It is a schematic diagram of a pressurized tool for installing an electric heater on the bulkhead of a manned spacecraft according to an embodiment of the present invention. The pressurized tooling used for installing the electric heater on the bulkhead of the manned spacecraft of the present invention includes four functional sub-modules: a sliding adjustment module, a shape-forming compression module, a bridge-shaped support module, and an adsorption module. in:

[0018] Sliding adjustment module: composed of butterfly adjusting bolt 1, slider 2, and ball screw 3. The butterfly adjusting bolt 1 passes through the slider 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com