Tire road impact test device

An impact test and road technology, applied in the direction of impact test, vehicle impact test, automobile tire test, etc., can solve the problems of sidewall cord breakage, easy impact on the rim, tire bulge, etc., achieving low cost, flexible assembly and disassembly , the effect of widely promoting the application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

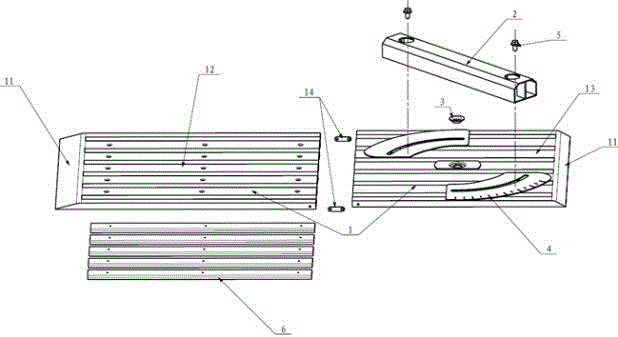

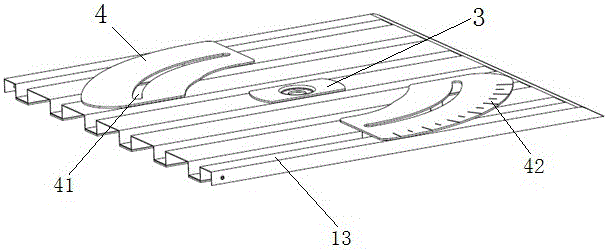

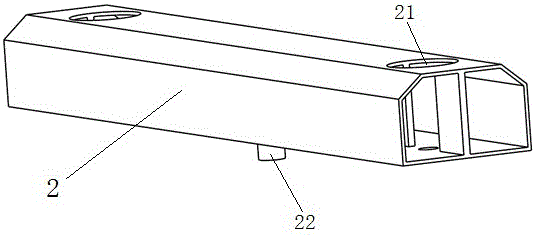

[0017] Such as figure 1 , 2 , 3, a tire road impact test device, including a supporting plate 1 and an impact beam 2, the supporting plate 1 is fixed on the foundation ground, the two ends of the supporting plate 1 are driving guide slopes 11, and the impact beam 2 Hinged on the supporting plate 1 through the rotating shaft 22 at the center, the two ends of the impact beam 2 are provided with fixing screw holes 21; on the supporting plate 1, a pair of fan-shaped plates 4 are fixed and fixed symmetrically with the axis of the rotating shaft 22 as the center. The fan-shaped plate 4 is provided with an arc groove 41 matching the fixing screw hole 21, and the bolt 5 connects the supporting plate 1 and the fan-shaped plate 4 through the fixing screw hole 21 and the arc groove 41. At least one fan-shaped plate 4 Angle scale marks 42 are provided.

[0018] In order to avoid affecting the test results, it is required that the supporting plate 1 can be fixed on the foundation ground ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com