IGBT fault monitoring device and method

A technology for monitoring devices and faults, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc. It can solve the problems of consuming maintenance costs and ignoring the impact, and achieve the effect of avoiding blind replacement and saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

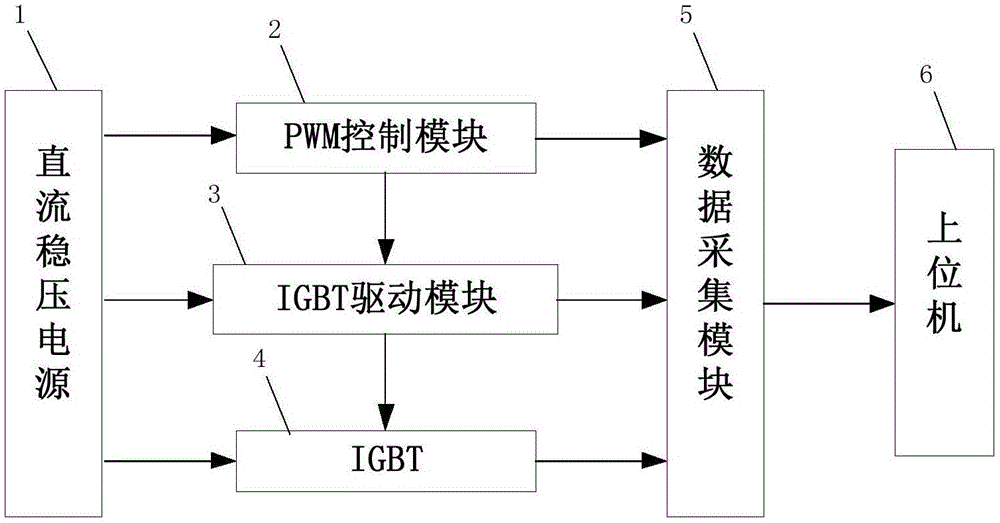

[0034] combine figure 1 As shown, an IGBT fault monitoring device includes a DC stabilized power supply 1 , a PWM control module 2 , an IGBT drive module 3 , an IGBT4 , a data acquisition module 5 and a host computer 6 .

[0035] Among them, the PWM control module 2 is used to generate pulses with adjustable frequency and amplitude, wherein one pulse signal is sent to the data acquisition module 5 , and the other pulse signal is sent to the IGBT drive module 3 .

[0036] The IGBT drive module 3 is used to amplify the received pulse signal, wherein one amplified pulse signal is sent to the data acquisition module 5, and the other amplified pulse signal is sent to the gate of the IGBT4.

[0037] The IGBT4 is used to turn on and off repeatedly under the action of the IGBT driving module 3 and generate an on-off signal, and the generated on-off signal is sent to the data acquisition module 5 through the emitter of the IGBT4.

[0038] The data collection module 5 is used for uploa...

Embodiment 2

[0043] In Embodiment 2, a monitoring method for IGBT failure is proposed, and the monitoring device used includes a DC stabilized power supply, a PWM control module, an IGBT drive module, an IGBT, a data acquisition module and a host computer.

[0044] A monitoring method for IGBT faults, comprising the steps of:

[0045] ① Pulses with adjustable frequency and amplitude are generated by the PWM control module 2, wherein one pulse signal is sent to the data acquisition module 5, and the other pulse signal is sent to the IGBT drive module 3;

[0046] ② The IGBT drive module 3 amplifies the received pulse signal, wherein the amplified pulse signal is sent to the data acquisition module 5, and the amplified pulse signal is sent to the IGBT4 gate;

[0047] ③ IGBT4 is repeatedly turned on and off under the action of IGBT drive module 3 and generates an on-off signal, which is sent to the data acquisition module through the emitter of IGBT4;

[0048] ④The data acquisition module 5 u...

Embodiment 3

[0058] This embodiment 3 proposes an analysis method for an IGBT failure, which is based on the device for an IGBT failure in the above-mentioned embodiment 1, which includes the following steps:

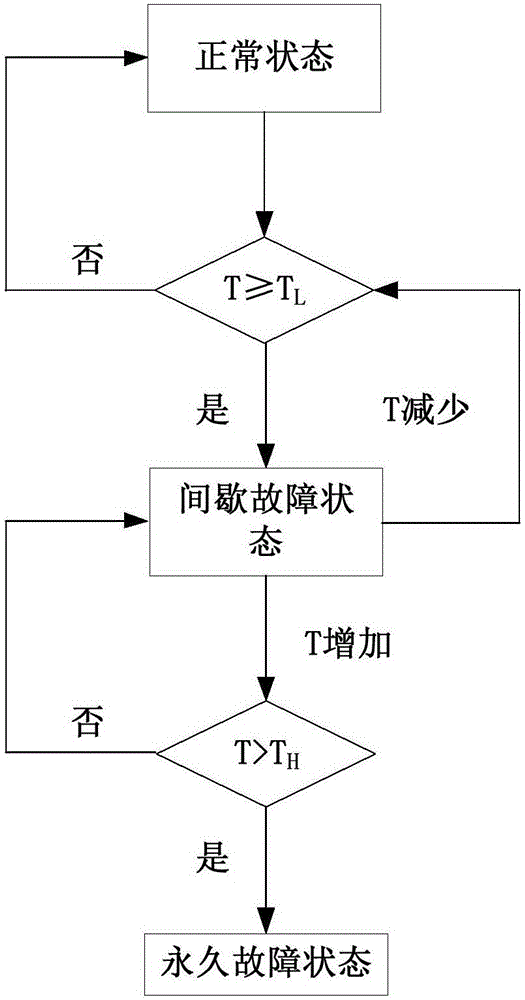

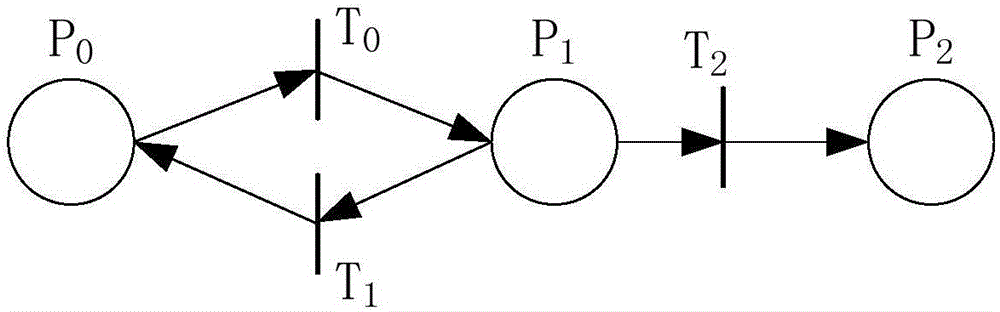

[0059] a Divide IGBT4 into normal state, intermittent fault state and permanent fault state, and establish the logical relationship of the three states, such as figure 2 shown; where: the failure rate of IGBT4 is set to T, and the threshold for IGBT4 to change from normal state to intermittent fault state is T L , the threshold for IGBT4 to change from intermittent fault state to permanent fault state is T H .

[0060] The number of IGBT4 failures will increase as the working time increases. When the failure rate T increases to T L After that, IGBT4 will enter the intermittent fault state, and the increase in the number of intermittent faults will cause cumulative damage to the structure of IGBT4, resulting in an increase in the fault frequency of IGBT4, and T will continue to in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com