Catalyst for preparing ethylstyrene styrene by side chain alkylation of toluene and methanol and its application

A catalyst and styrene technology, applied in physical/chemical process catalysts, molecular sieve catalysts, organic chemistry, etc., can solve the problems of low activity and low selectivity of ethyl styrene and styrene, and achieve the goal of improving catalytic activity and methanol utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

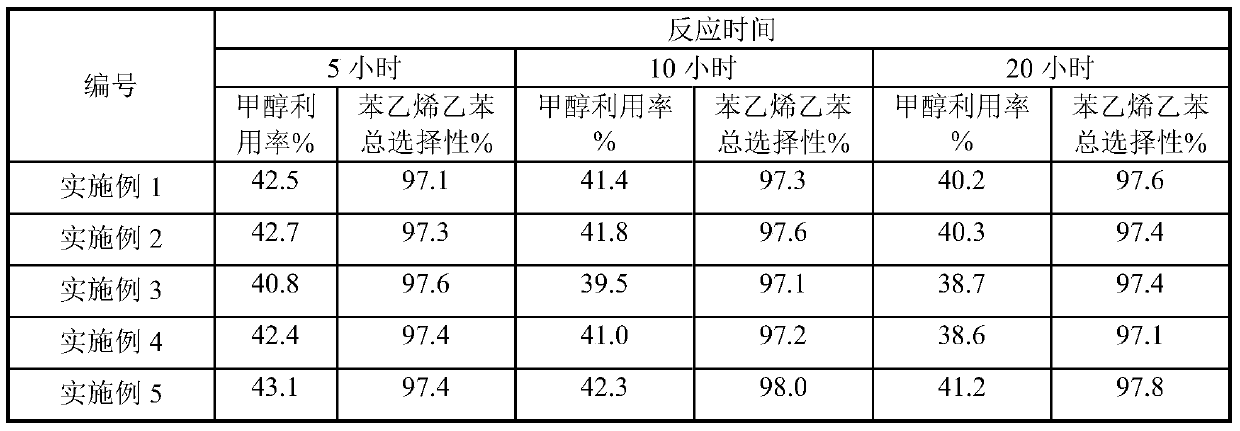

[0031] Take silicon aluminum than SiO 2 / Al 2 o 3 = NaX molecular sieve of 2.19, with KNO 3 solution, RbNO 3 solution and CsNO 3 The solution was ion-exchanged in turn, filtered and then dried at 100°C for 10 hours. After the exchange, the ion exchange degree of the sodium ion in the alkali metal ion exchange molecular sieve in the catalyst is above 85%. Then ferric nitrate is made into a solution, and the iron is impregnated on the above-mentioned modified molecular sieve material. The content of catalyst iron after loading is 0.8%.

[0032] The catalyst obtained above is pressed into pellets of 40 to 60 meshes, and loaded into a reactor, at normal pressure, the molar ratio of toluene to methanol is 6, in 2.0 hours -1 Liquid space velocity, 425°C, N 2 Activity evaluation was performed at a flow rate of 10 ml / min. The results are shown in Table 1.

Embodiment 2

[0034] Take silicon aluminum than SiO 2 / Al 2 o 3 = NaX molecular sieve of 2.19, with KNO 3 solution, RbNO 3 solution and CsNO 3 The solution was ion-exchanged in turn, filtered and then dried at 100°C for 10 hours. After the exchange, the ion exchange degree of the sodium ion in the alkali metal ion exchange molecular sieve in the catalyst is above 85%. Then cobalt nitrate is made into a solution, and the cobalt is impregnated on the above-mentioned modified molecular sieve material. The cobalt content of the supported catalyst is 0.9%.

[0035] The catalyst obtained above is pressed into pellets of 40 to 60 meshes, and loaded into a reactor, at normal pressure, the molar ratio of toluene to methanol is 6, in 2.0 hours -1 Liquid space velocity, 425°C, N 2 Activity evaluation was performed at a flow rate of 10 ml / min.

[0036] The results are shown in Table 1.

Embodiment 3

[0038] Take silicon aluminum than SiO 2 / Al 2 o 3 = NaX molecular sieve of 2.19, with KNO 3 solution, RbNO 3 solution and CsNO 3 The solution was ion-exchanged in turn, filtered and then dried at 100°C for 10 hours. After the exchange, the ion exchange degree of the sodium ion in the alkali metal ion exchange molecular sieve in the catalyst is above 85%. Then make a solution of chromium nitrate, and impregnate the chromium on the above-mentioned modified molecular sieve material. The chromium content of the supported catalyst is 1%.

[0039] The catalyst obtained above is pressed into pellets of 40 to 60 meshes, and loaded into a reactor, at normal pressure, the molar ratio of toluene to methanol is 6, in 2.0 hours -1 Liquid space velocity, 425°C, N 2 Activity evaluation was performed at a flow rate of 10 ml / min.

[0040] The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com