Process for the production of para-alkylated aromatics

A technology for alkylating aromatic hydrocarbons and alkylating reagents, which is applied in the field of aromatic hydrocarbon shape-selective alkylation reactions, and can solve problems such as increased side reactions, low utilization of methanol, and unreasonable distribution of reactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

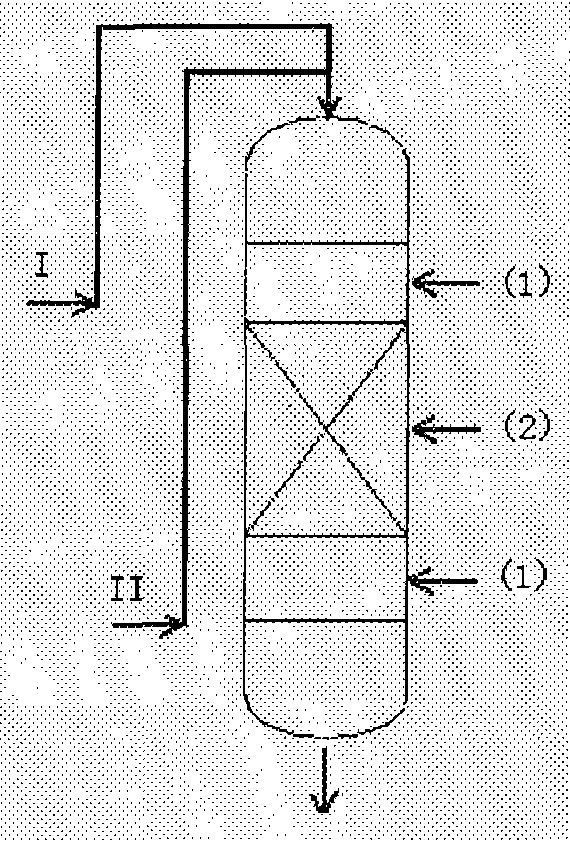

[0042] in the instruction manual figure 2 The described multi-bed fixed-bed reactor was filled with 10 g of catalyst A prepared in Comparative Example 1, and the alkylating agent stream was dispersed into equal or unequal multi-stage streams. Different beds of a bed reactor. That is, after the heat exchange, the hydrogen-containing aromatic hydrocarbon stream (I) and the normal temperature first-stage alkylating reagent stream (II) are fully mixed in the first-stage inert material layer, and then enter the first catalyst bed layer of the reactor, After the reaction, the obtained gas stream and the second normal-temperature methanol stream (III) introduced from the second-stage injection port are mixed, gasified and uniformly dispersed in the second-stage inert material layer, and then enter the second catalyst bed of the reactor, After the reaction, the obtained gas stream and the normal temperature methanol stream (IV) introduced by the injection port of the third section a...

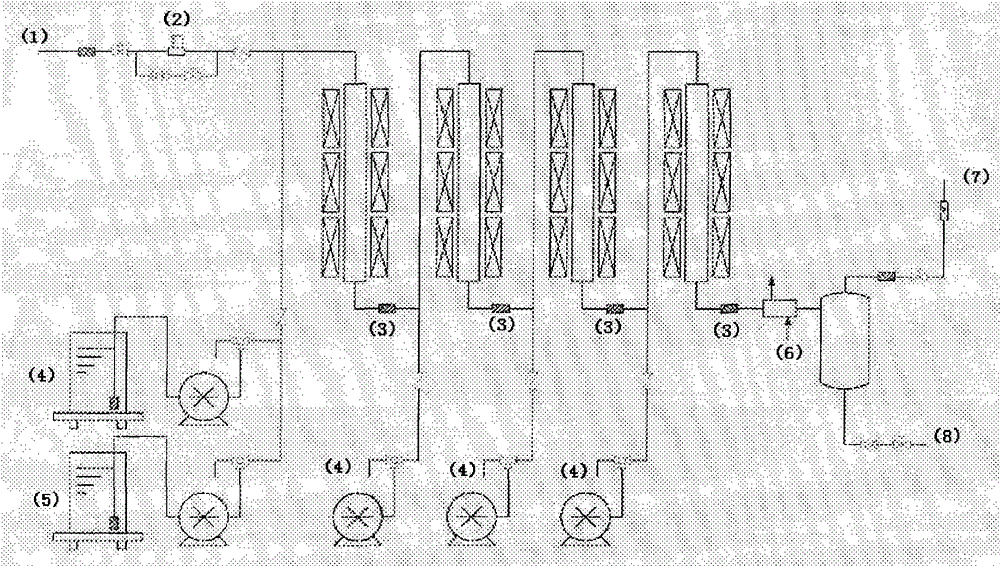

Embodiment 5~8

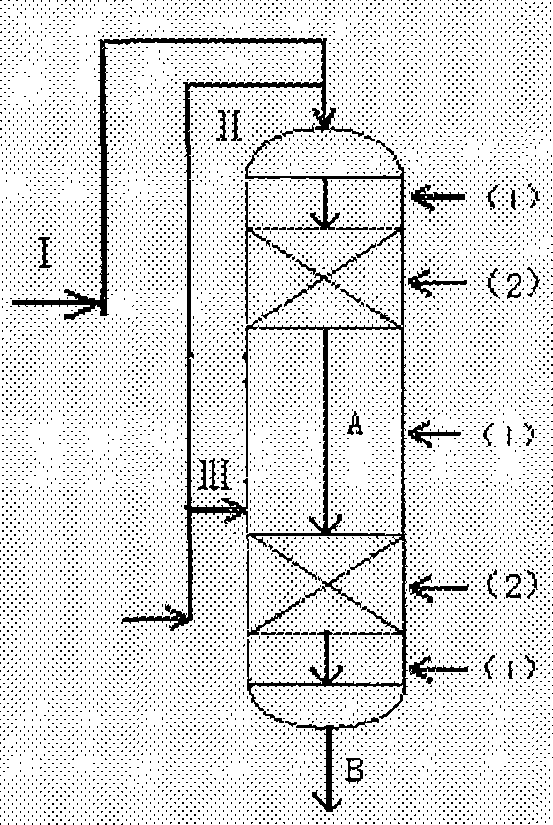

[0044] in the instruction manual image 3 The described multi-stage series-connected fixed-bed reactor is loaded with 10 g of catalyst B prepared in Comparative Example 2, and the alkylating agent stream is dispersed into multiple normal-temperature streams of equal or unequal amounts, respectively entering the multi-stage series-connected fixed bed from multiple injection ports. In the reactor, after heat exchange, the hydrogen-containing aromatic hydrocarbon stream (I) and the first stream of alkylating reagent (II) at normal temperature are mixed and vaporized in the inert layer of the first-stage reactor, and then enter the first-stage reactor. The catalyst bed layer, the gas stream obtained after the reaction and the normal temperature alkylating reagent stream (III) introduced from the injection port in the upper part of the second-stage reactor are mixed, gasified and uniformly dispersed in the ceramic ball layer, and then enter the second-stage reactor. After the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com