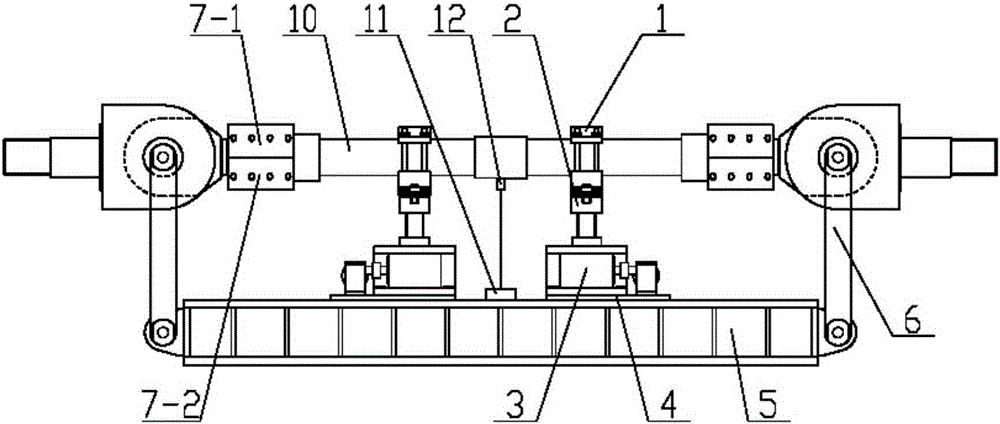

Four-point bending test device for pipe full-size evaluation

A four-point bending and test device technology, applied in the direction of using a stable bending force to test the strength of materials, measuring devices, analyzing materials, etc., can solve the problems of small load, high cost, inaccurate loading data, etc. Uniformity of force, large support load, and accurate loading data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

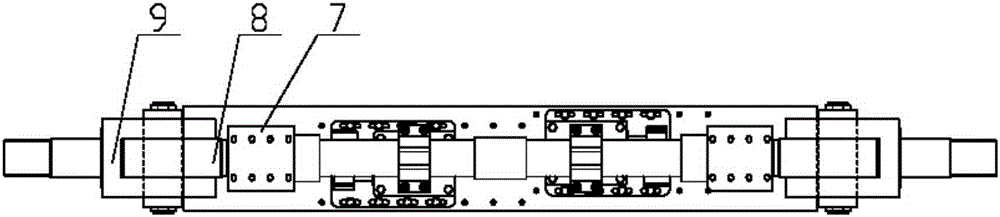

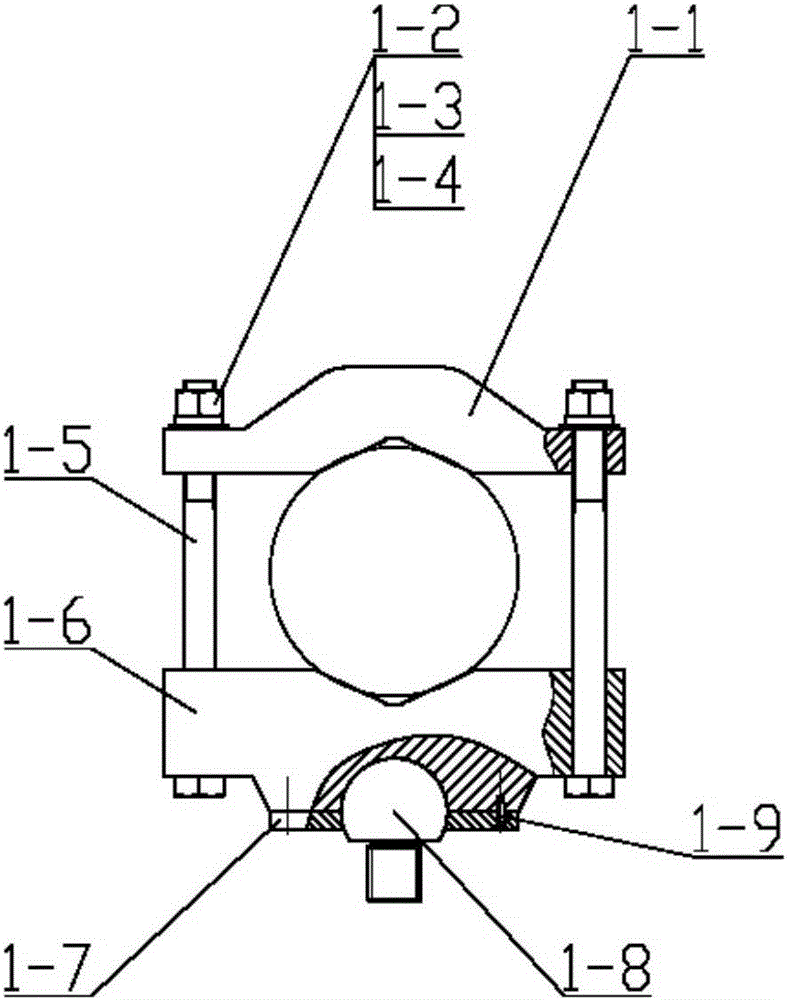

[0035] When installing, assemble the clamp assembly 1, the load cell 2, the electric lift 3 and the lift mounting plate 4 together to form a four-point bending actuator, and then use the bolts of the lift mounting plate 4 of the four-point bending actuator and the suspension bridge 5 Connect, loosen the hexagonal nut 1-2 of the clamp assembly, pull out the hexagonal bolt 1-5, remove the upper chuck 1-1, start the electric elevator 3, adjust the height of the clamp assembly 1, and wait for the lower clamp assembly 1 Stop the electric elevator 3 when the chuck 1-6 is at the same height as the lower half 7-2 of the buckle 7, and place the sample 10 flat on the lower half 7-2 of the buckle 7 and the lower chuck 1-6, Connect the upper body 7-1 of the buckle nut 7 with the lower half body 7-2 of the buckle nut 7 with bolts, and then connect the hex nut 1-2, spring washer 1-3, flat washer 1-4, and hexagon bolt 1-5. The upper chuck 1-1 is connected with the lower chuck 1-6, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com