A kind of preparation method of yogurt powder, yogurt formula powder and yogurt powder

A technology of yogurt powder and formula powder, applied in the directions of dairy products, whey, application, etc., can solve the problems of no natural yogurt flavor and taste, no obvious human intestinal health effect, no lactic acid bacteria fermentation process, etc. Gut health, strong market demand prospects, the effect of improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

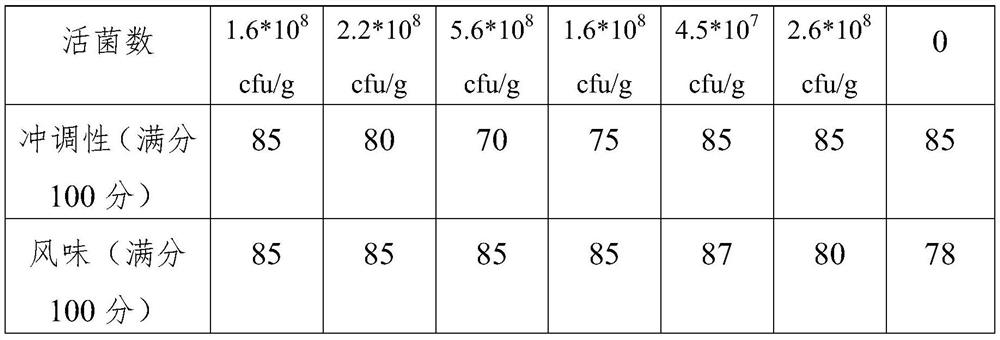

Embodiment 1

[0043] This embodiment provides a kind of yogurt powder, and this yogurt powder is prepared by the following steps:

[0044] (1) Mixing: add 700Kg purified water to the mixing tank, heat up to 60°C, add 100Kg whey powder, 80Kg skim milk powder, 60Kg whole milk powder, 50Kg maltodextrin, 10Kg polydextrose, 1.5Kg oligomer Galactose, 5Kg soybean lecithin, stir evenly.

[0045] (2) Hydration: Control the temperature at 50-55°C and let it stand for 1 hour to hydrate.

[0046] (3) Fermentation: Homogenize the feed solution at 20Mpa, sterilize at 90°C for 5 minutes, cool to 42°C, add starter, ferment until the pH value reaches 4.1-4.5, and stop the fermentation.

[0047] (4) Powder spraying: After the fermented yoghurt is homogenized at 16Mpa, it is directly spray-dried. The spray-drying conditions are: the inlet air temperature is 175°C, and the wind speed and flow rate are adjusted to an outlet temperature of 85°C.

[0048] Wherein, the whey powder is Irish D90 whey powder, the s...

Embodiment 2

[0051] Compared with Example 1, the only difference lies in: spray drying conditions: the inlet air temperature is 175°C, and the wind speed and flow rate are adjusted to the outlet temperature of 75°C.

[0052] The yogurt powder prepared in this example has a protein content of 17%, a water content of 3.2%, and a viable count of 2.2*10 8 cfu / g.

Embodiment 3

[0054] Compared with Examples 1 and 2, the only difference lies in: spray drying conditions: the inlet air temperature is 175°C, and the wind speed and flow rate are adjusted to an outlet temperature of 65°C.

[0055] The yogurt powder prepared in this example has a protein content of 17%, a water content of 4.8%, and a viable count of 5.6*10 8 cfu / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com