Cover plate coloring method and mobile terminal

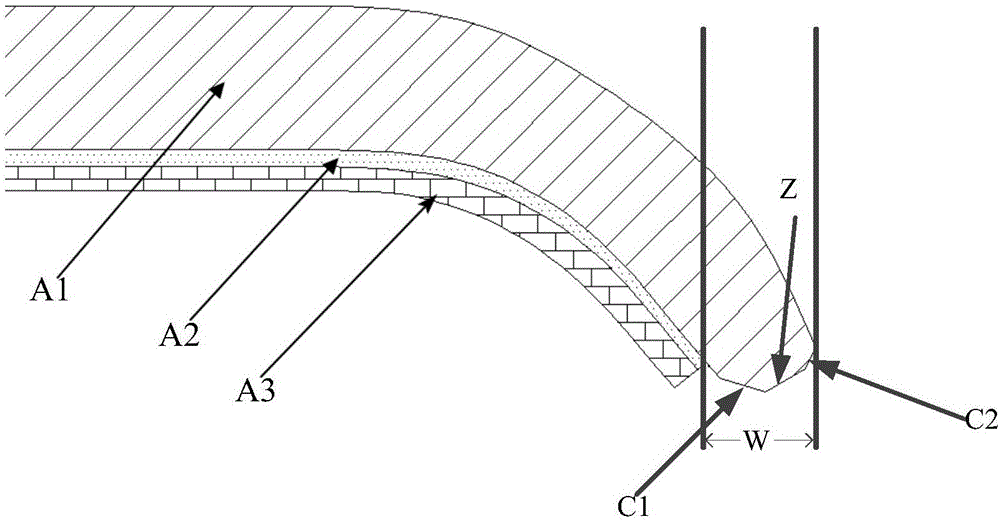

A mobile terminal and cover technology, applied in printing, printing devices, devices for coating liquid on the surface, etc., can solve problems such as air bubbles, bottom penetration, and wrinkles in the arc area of the cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

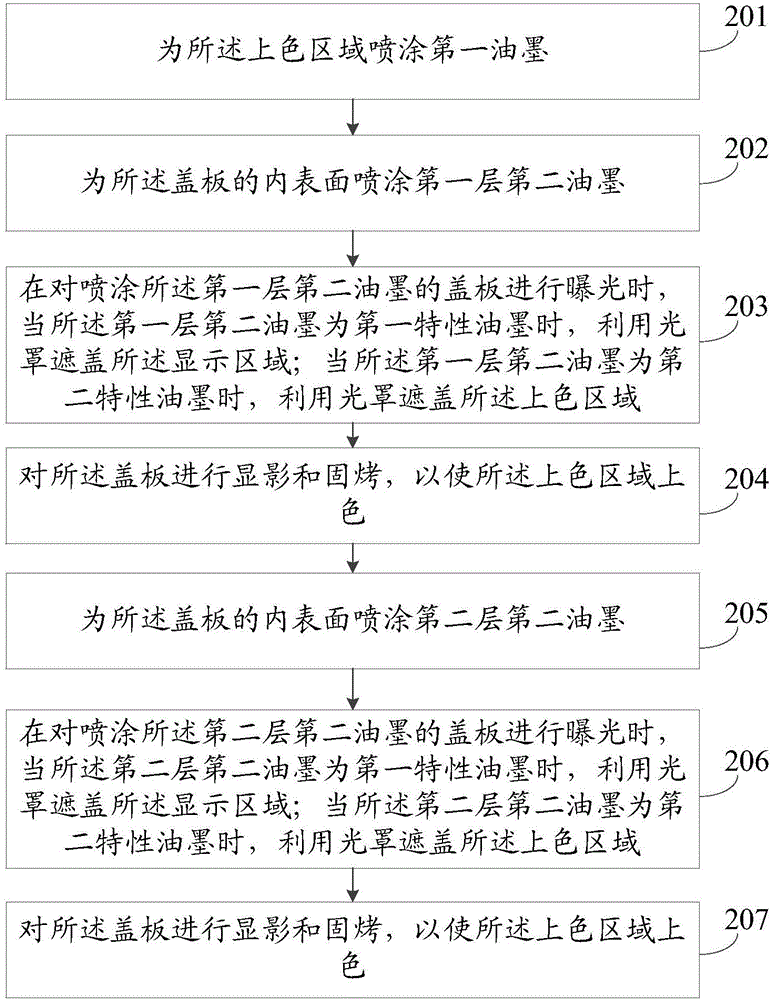

[0016] refer to figure 2 , which shows a flow chart of the steps of an embodiment of a method for coloring a cover plate according to an embodiment of the present invention, and the specific steps include:

[0017] Step 201, spraying a first ink on the colored area.

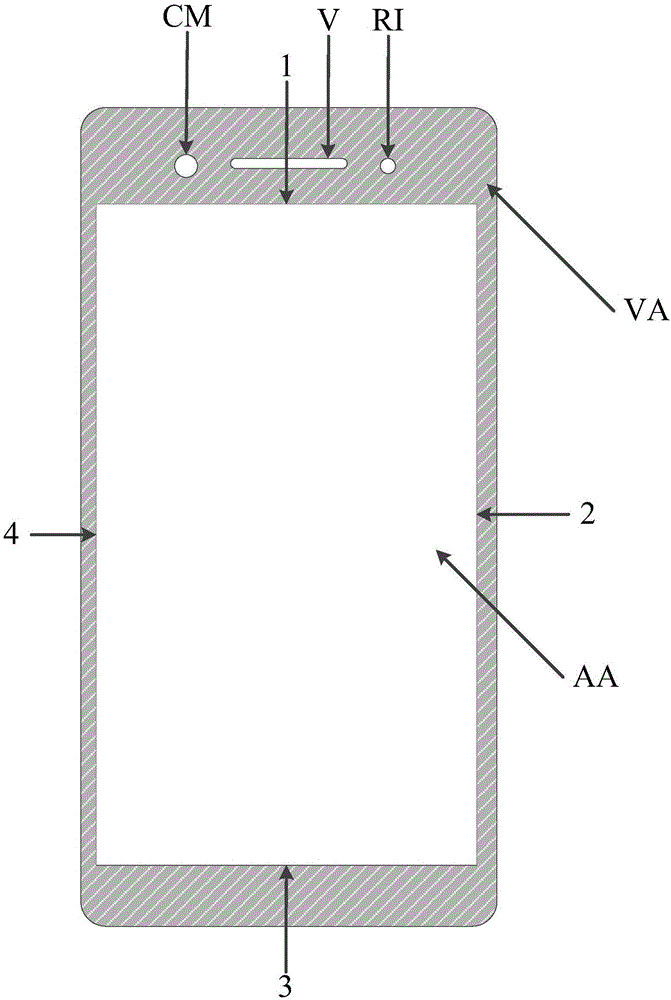

[0018] The embodiment of the present invention is applied to a 3D curved cover plate of a mobile terminal, and the cover plate includes two areas: a display area and a colored area; the display area is a touch area displayed on the cover plate and the mobile terminal The corresponding area; the colored area is the area on the cover except the display area, refer to image 3 , image 3 A schematic diagram of a cover surface of the present invention is shown; image 3 AA in is the display area, and VA is the colored area. In addition, the 3D curved cover plate may include 2 curved surfaces or 4 curved surfaces; the curved surfaces all belong to the colored area of the cover plate; since this step is the colo...

Embodiment 2

[0030] refer to Figure 4 , which shows a flow chart of the steps of another embodiment of the cover coloring method according to the embodiment of the present invention, and the specific steps include:

[0031] Step 401 , spraying black photoresist ink with a preset width on the junction of the display area and the colored area.

[0032] Step 402 , exposing, developing and curing the cover plate.

[0033] Because when other layers of the screen of the mobile terminal are bonded to the cover plate, certain errors will occur; in order to reduce the impact of the error on the user’s vision during the bonding, the coloring area of the cover plate can be Before coloring, after cleaning the cover plate, spray black photoresist ink with a preset width at the junction of the display area and the coloring area; wherein, refer to image 3 , the connection between the display area and the colored area includes four places: the edge of the display area pointed to by 1, 2, 3, and 4; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com