A method and control device for on-line automatic roll shifting of work rolls of a skin pass mill

A work roll and skin pass mill technology, applied in contour control, metal rolling, etc., can solve the problems affecting the control reliability and accuracy of skin pass mill, unstable rolling zero position, time-consuming and laborious roll shifting operation, etc. Achieve the effect of avoiding precision adjustment and correction, ensuring stability and precision, and improving roller shifting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

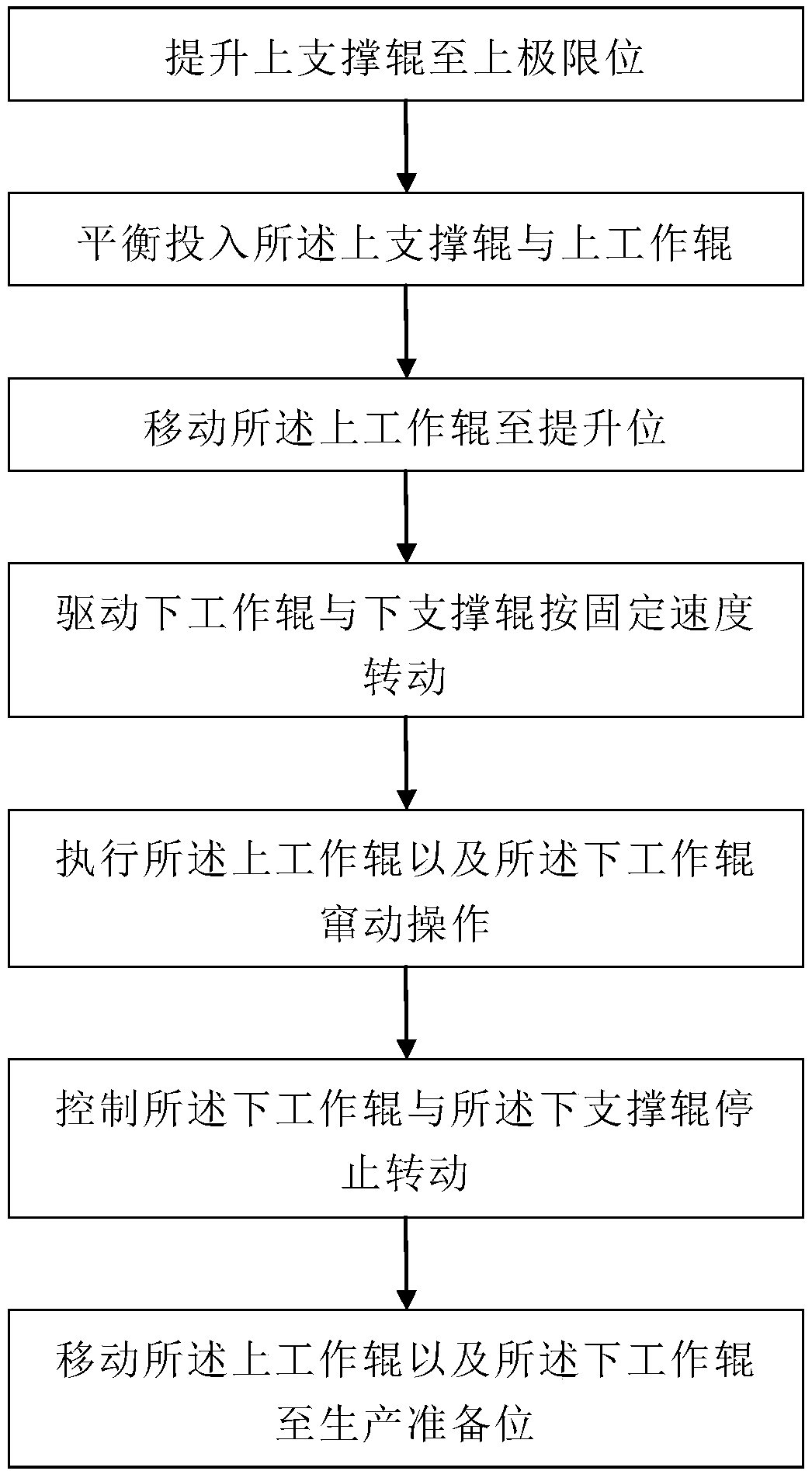

[0023] The embodiment of the present application provides an online automatic roll shifting method for the work rolls of the temper mill to solve the problem that the off-line roll shifting method of the temper mill in the prior art causes time-consuming and laborious roll shifting operations and unstable rolling zero position, which seriously affects Reliability and precision of temper mill control; achieve the technical effect of improving the efficiency of roll shifting and reducing the impact of roll shifting on the stability and control accuracy of the unit.

[0024] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

[0025] For the separate roll shifting control of the upper and lower work rolls, the upper roll area is implemented according to the conventional roll shifting method; the lower roll area is operated online according to a certain rotation speed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com