Solid-web large-section spiral stair box girder shaped like Chinese character ''mu'' and manufacturing method

A technology of spiral staircase and large section, applied in the direction of stairs, etc., to achieve the effect of strong overall shape, beautiful appearance, and reduction of welding deformation of welding seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

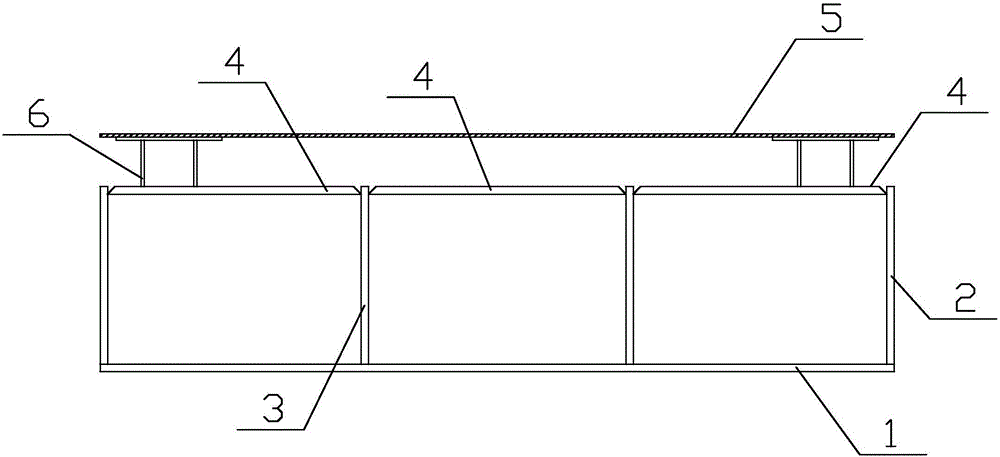

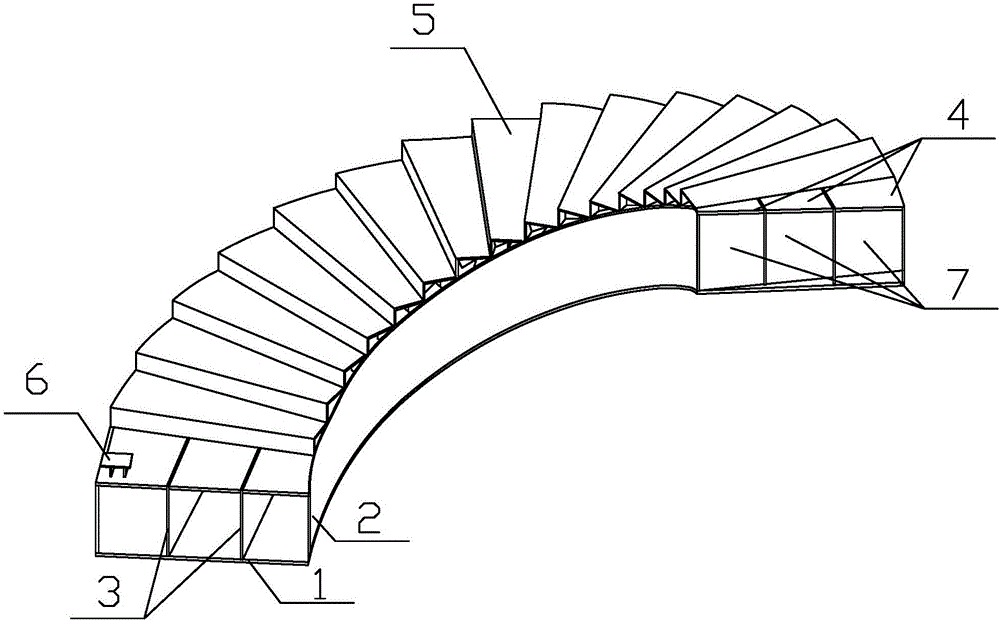

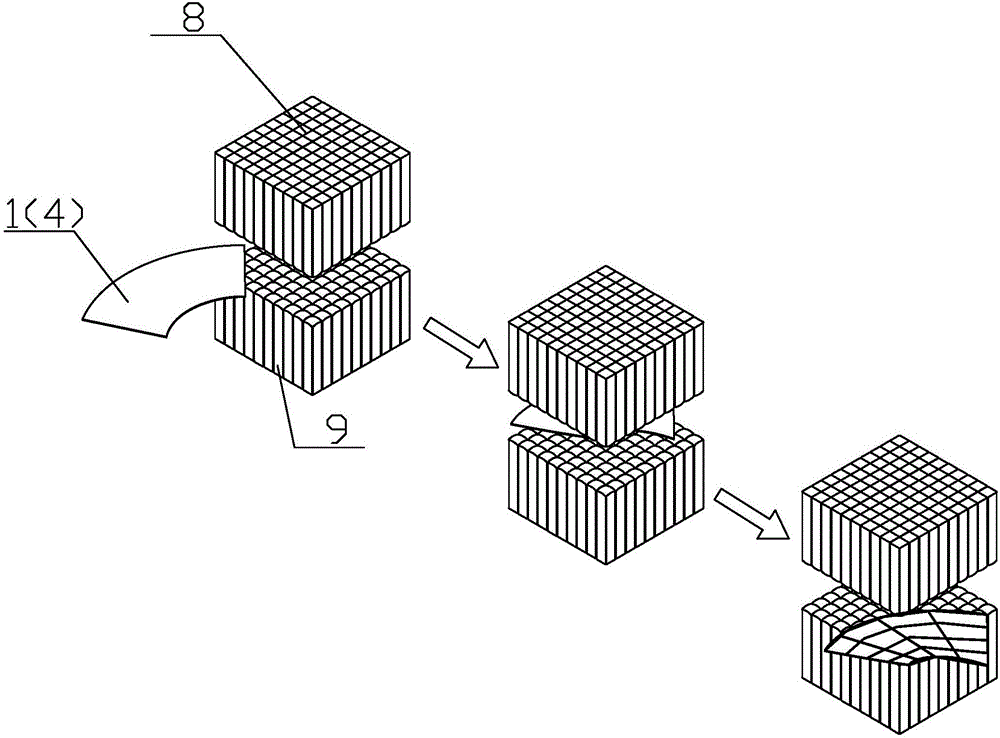

[0022] Such as Figure 1-6 As shown, the present invention discloses a solid-web type large-section spiral staircase mesh-shaped box beam, which includes a mesh-shaped box body, a pallet 6 and a step board 5. The mesh-shaped box body is enclosed by a large cross-section spiral surface bottom plate 1, two sides and middle bent and twisted webs (2, 3), and an upper small cross-section strip spiral surface cover plate 4. The large cross-section spiral surface bottom plate 1 is an ultra-wide panel that rises in a spirally curved shape; the middle and side curved and twisted webs (2, 3), a total of four pieces of equal width, are evenly spaced in the vertical direction. On the upper surface of the spiral bottom plate 1; the top strip-shaped spiral cover plate 4 is embedded between the webs (the bent and twisted webs 2 on both sides and the middle bent and twisted web 3) and the upper surface is connected to the bent and twisted webs The tops of the webs (2, 3) are flush.

[0023] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com