Hollow cylinder for stud welding machine

A hollow cylinder and stud welding machine technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as easy wear, clip clamping failure, fatigue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

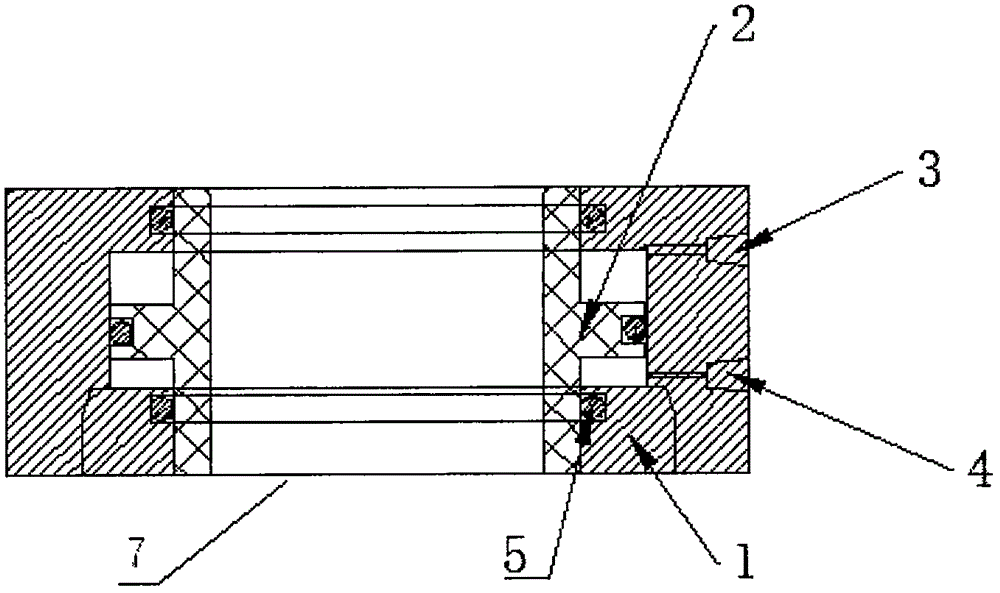

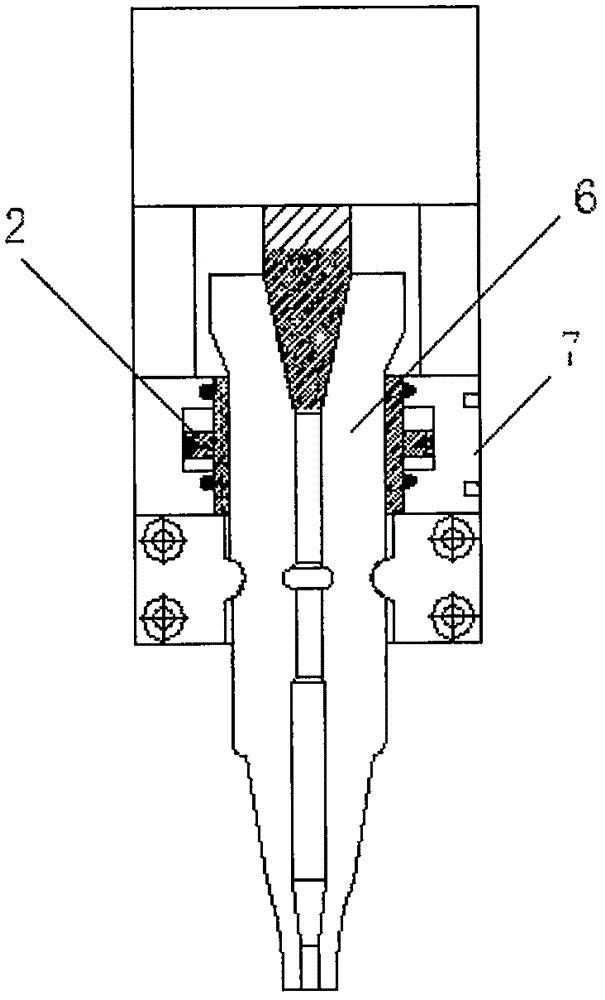

[0010] Such as figure 1 , figure 2 As shown, a hollow cylinder for a stud welding machine is composed of: an outer cylinder body 1 of the cylinder, a hollow piston body 2 of the cylinder, an air inlet and outlet A3 of the cylinder, an air inlet and outlet B4 of the cylinder, and a sealing ring 5 of the cylinder.

[0011] The hollow cylinder 7 is set outside the clamp nozzle 6 of the stud welding machine, and the cylinder sealing ring 5 inside the hollow cylinder 7 plays a sealing role. Closed, air inlet and outlet B4 of the cylinder intake air, the hollow piston 2 of the cylinder moves upward, and the stud welder jaw 6 opens. Because the present invention adopts the above structure, it overcomes the problem that the traditional stud welding machine jaws are prone to wear and fatigue after long-term work, which causes clamping failure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com