Oil expression system with controllable oil expression assembly

A technology of components and pressing rods, applied in the direction of presses, manufacturing tools, etc., can solve the problems of affecting the oil output efficiency of the pressing mechanism, troublesome operation of the pressing mechanism, and difficult to clean the pressing rods and pressing chambers, so as to achieve compact structure, easy processing, Good work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

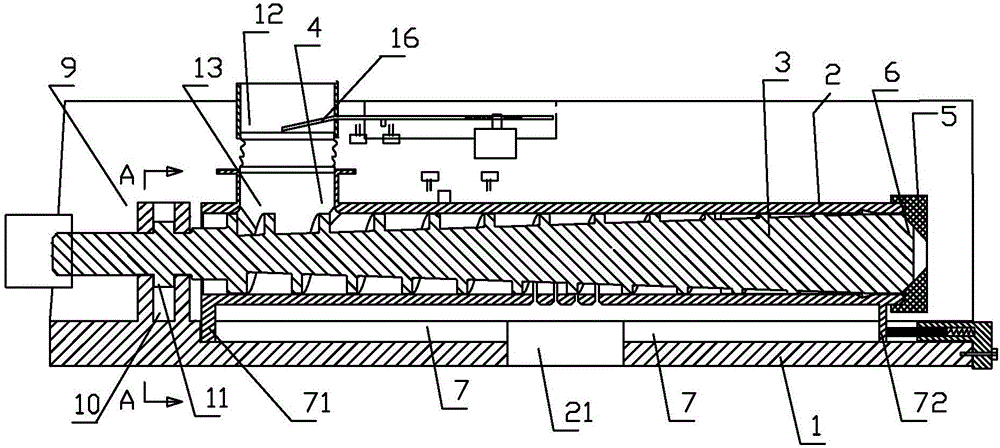

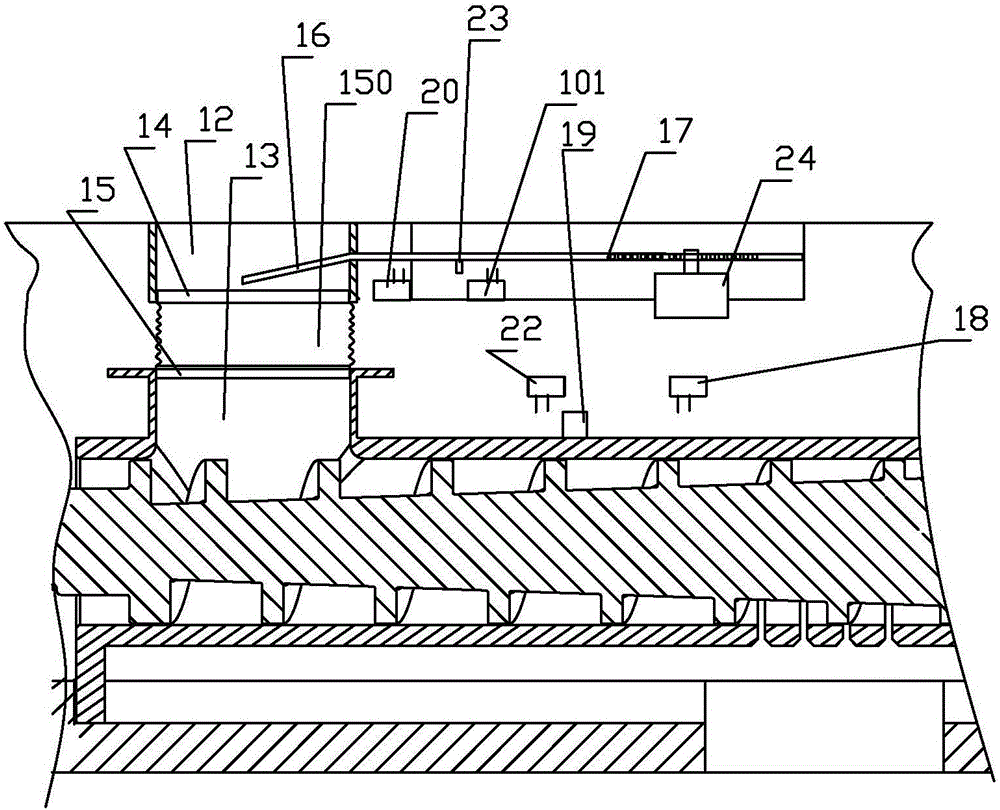

[0057] Embodiment 1: as Figure 1 to Figure 15 As shown, an oil extraction system with a controllable oil extraction component includes a frame 200, a feeding device 201 (feed box), a transmission mechanism 300, and an electric controllable oil extraction component are arranged on the frame 200. The oil press mainly includes a frame 200, a feeding device 201 (feed box), a transmission mechanism 300, and an electric controllable oil pressing assembly are arranged on the frame 200.

[0058] The transmission mechanism 300 includes a motor 301 and a bevel gear set, and the transmission shaft of the motor is connected to the bevel gear set.

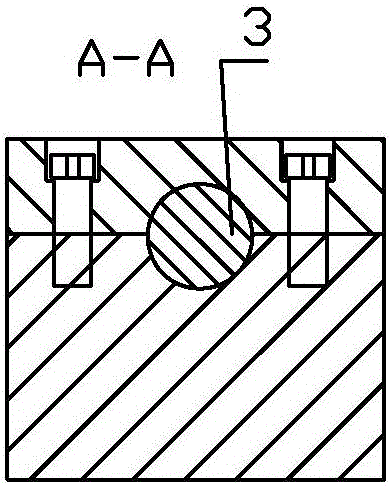

[0059] The electric controllable oil pressing assembly includes a component seat 1, a pressing chamber 2, and a pressing rod 3. The pressing rod 3 is located in the pressing chamber; the pressing chamber 2 includes a conveying material section and a pressing section; The conveying section and the pressing section are arranged in sequence, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com