Cutter head fine adjustment mechanism of hair clippers

A technology of fine-tuning mechanism and hair clipper, applied in metal processing and other directions, can solve problems such as large adjustment range and difficulty in meeting customer needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

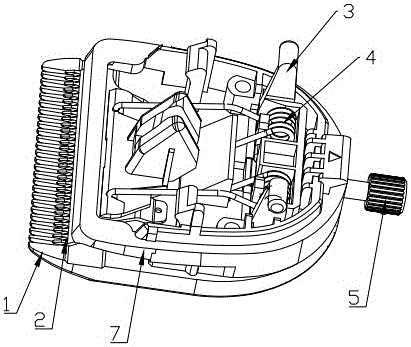

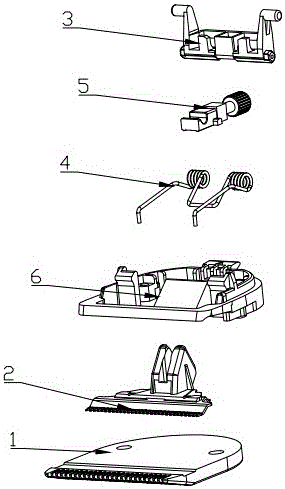

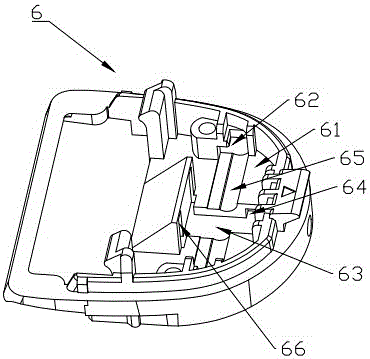

[0025] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0026] As shown in the figure, a knife head fine-tuning mechanism of hair clippers includes a static knife head 1, a moving knife head 2, and a rotating shaft 3. An elastic resisting member 4 is sleeved on the rotating shaft 3, and the elastic resisting member 4 Collide with the movable cutter head 2, so that the movable cutter head 2 is pressed against the static cutter head 1; it also includes a fine-tuning assembly 5, which includes a fixed screw sleeve 51 and an adjusting screw 52; the adjusting screw 52 passes through The fixed screw sleeve 51 is connected to the rotating shaft 3 .

[0027] By fixing the screw sleeve 51, the linear motion of the adjusting screw 52 can be realized by turning the adjusting screw 52, thereby driving the rotating shaft 3 to rotate, realizing the forward and backward movement of the movable cutter head 2, thereby realizing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com