A fine-tuning mechanism for a head of a hair clipper

A technology of fine-tuning mechanism and hair clipper, applied in metal processing and other directions, which can solve the problems of large adjustment range and difficult to meet customer needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

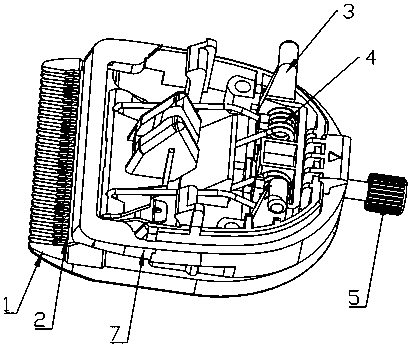

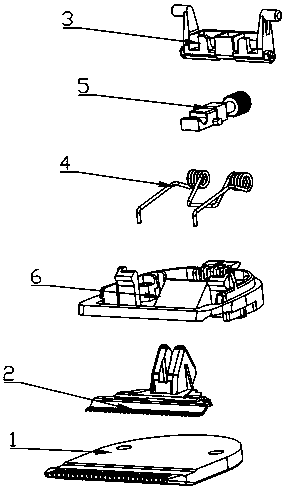

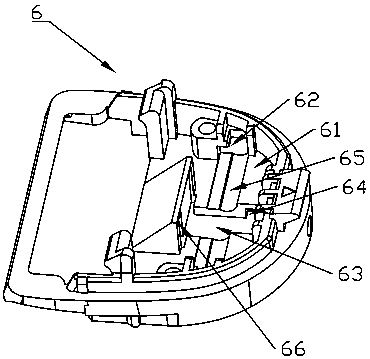

[0025] The embodiments of the present invention will be further described below in conjunction with the drawings:

[0026] As shown in the figure, a fine adjustment mechanism for the cutter head of a hair clipper includes a static cutter head 1, a movable cutter head 2, and a rotating shaft 3. The rotating shaft 3 is sleeved with an elastic pressing member 4, and the elastic pressing member 4 The movable cutter head 2 is pressed against the movable cutter head 2 so that the movable cutter head 2 is pressed against the static cutter head 1; it also includes a fine adjustment assembly 5 that includes a fixed screw sleeve 51 and an adjustment screw 52; the adjustment screw 52 passes through The fixed screw sleeve 51 is connected to the rotating shaft 3.

[0027] Through the fixed screw sleeve 51, the linear movement of the adjusting screw 52 can be realized when the adjusting screw 52 is rotated, thereby driving the rotation shaft 3 to rotate, realizing the moving blade 2 to move back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com