A workpiece processing method for a graphite processing machine

A processing method and technology of processing machines, which are applied in stone processing equipment, work accessories, manufacturing tools, etc., can solve the problems of fixed size of oil curtain seal and difficult collection and reuse of sealed oil, so as to achieve uniform oil output and avoid closed oil. loss, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

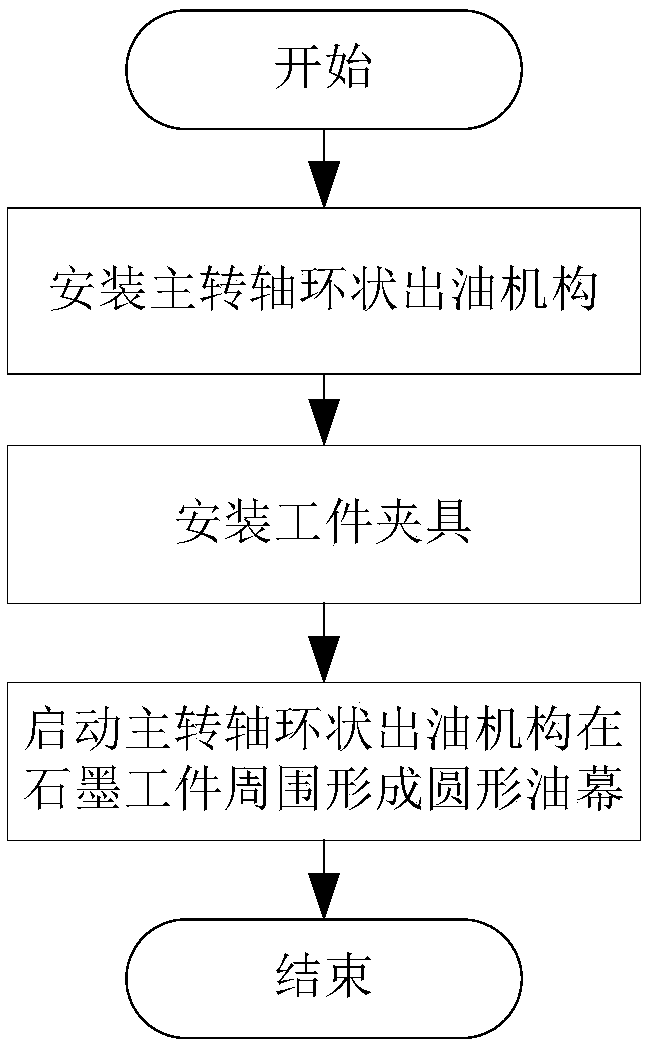

[0030] Such as Figure 1-8 As shown, a kind of workpiece processing method for graphite processing machine disclosed by the present invention comprises the following steps:

[0031] Step 1, install the main shaft annular oil outlet mechanism on the main shaft shell of the graphite processing machine, and make the machine tool spindle protrude from the lower end of the main shaft annular oil outlet mechanism;

[0032] Step 2, install the workpiece fixture on the workbench of the graphite processing machine, and make the center of the workpiece fixture correspond to the center position of the workbench;

[0033] Step 3, installing and clamping the graphite workpiece on the workpiece fixture, and then starting the ring-shaped oil outlet mechanism of the main shaft, forming a circular oil curtain surrounding the graphite workpiece under the machine tool spindle;

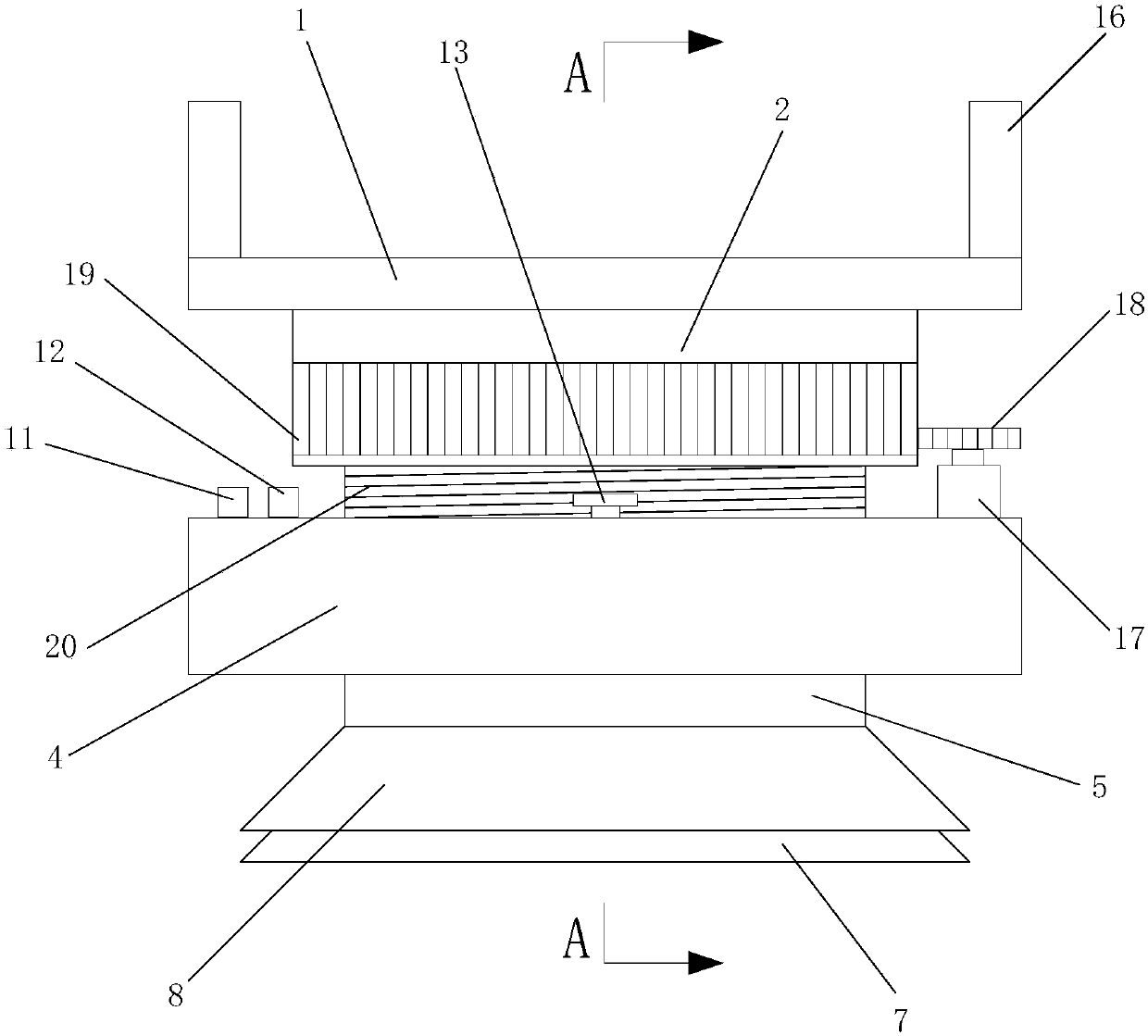

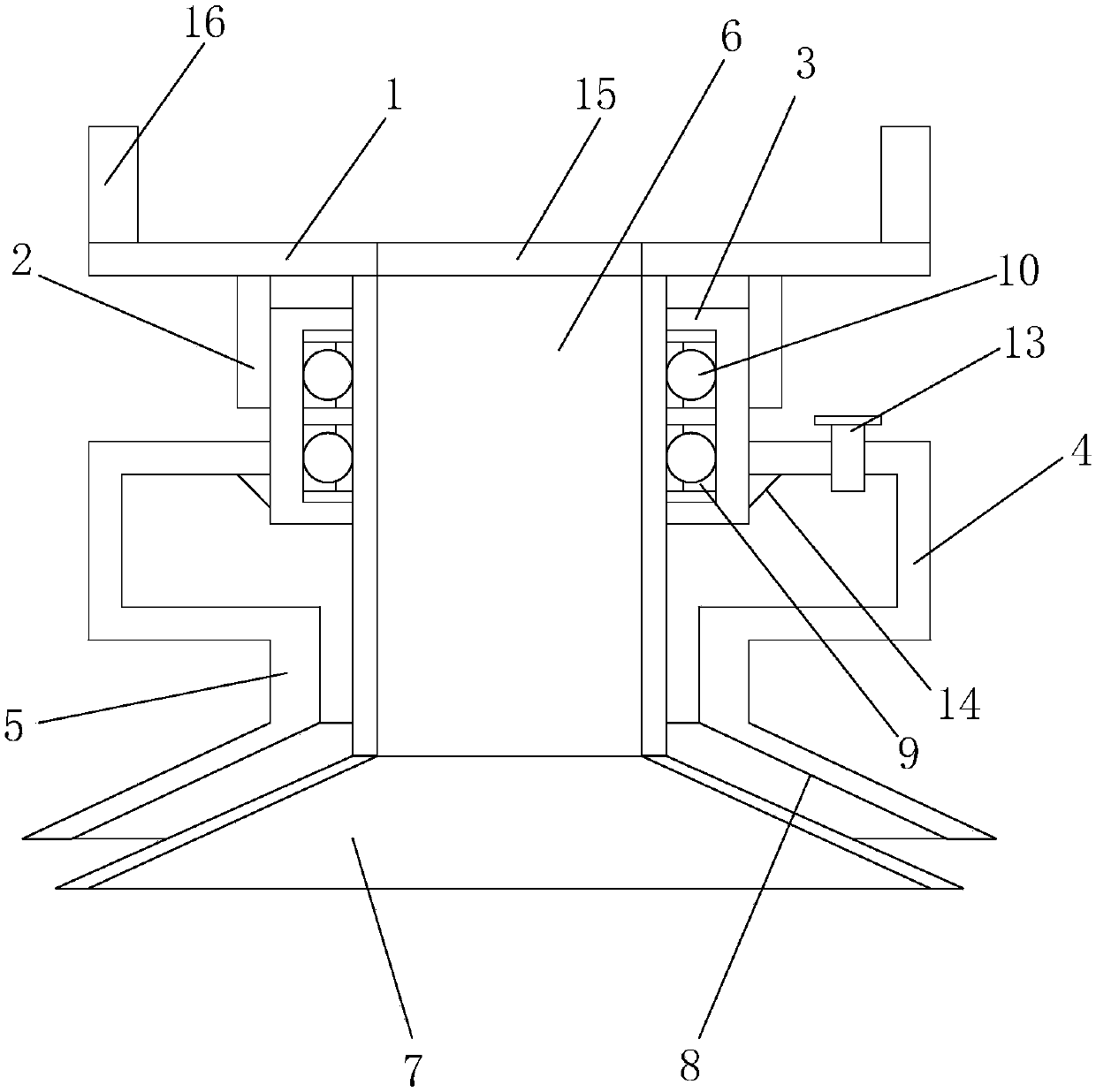

[0034] In the above steps, the main shaft annular oil outlet mechanism includes: mounting bracket 1, limit sleeve 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com