Nano-inorganic composition and coating method using same

A nano-inorganic and composite technology, applied in the direction of nanotechnology, nanotechnology, and devices for coating liquid on the surface, can solve the problems of reduced durability, whitening, and difficulty in achieving smooth coatings, and achieve strong weather resistance and excellent The effect of antimicrobial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

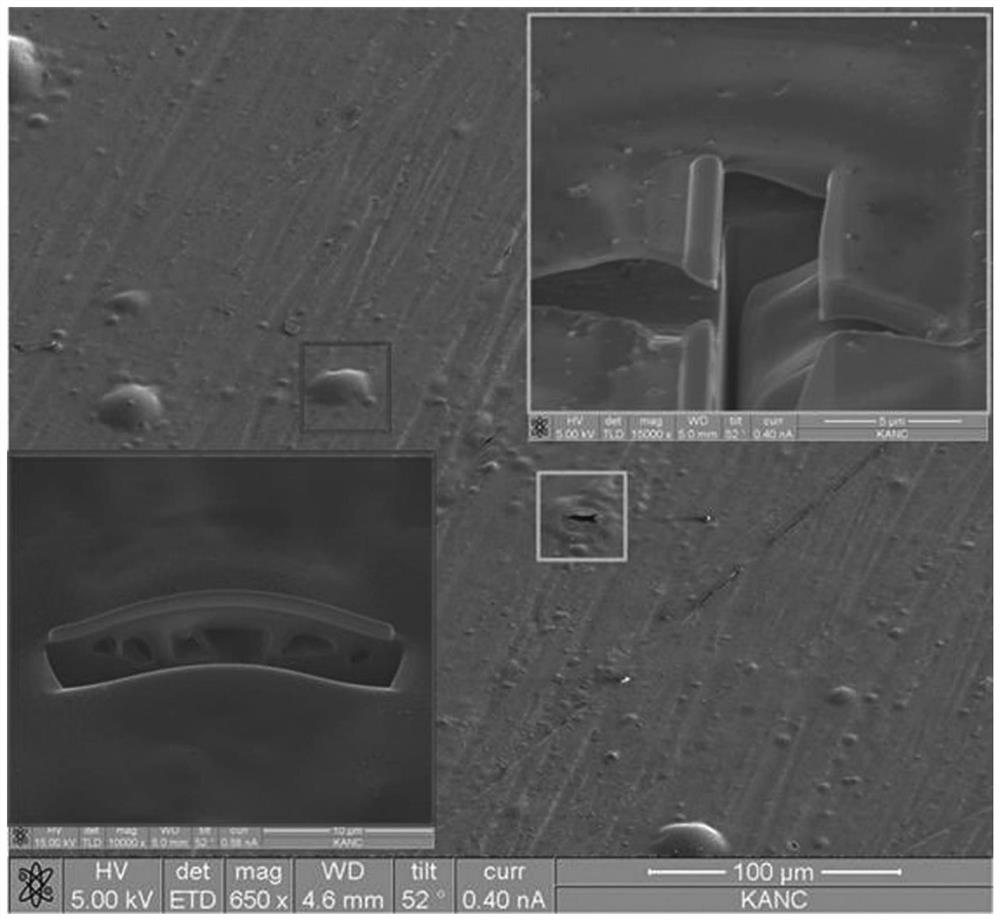

Image

Examples

Embodiment

[0055] Preparation of the composition

[0056] The composition ratio of the nano inorganic composition according to the present invention was set as follows to prepare.

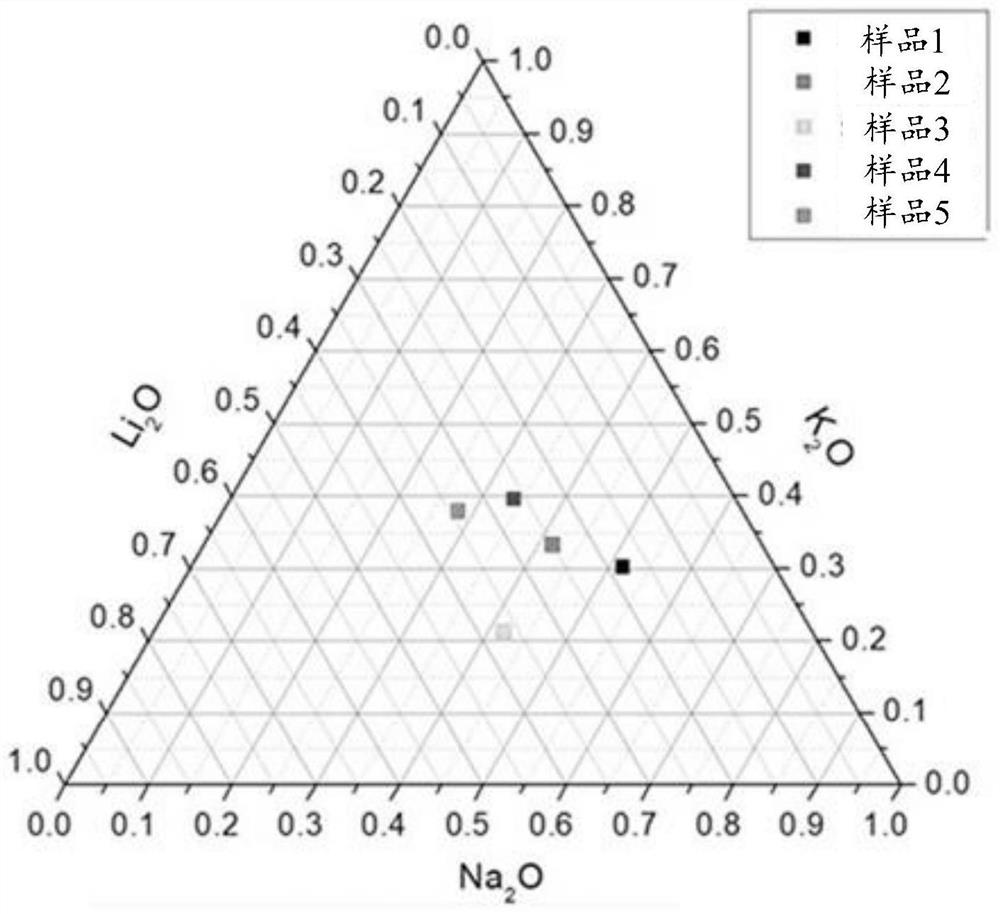

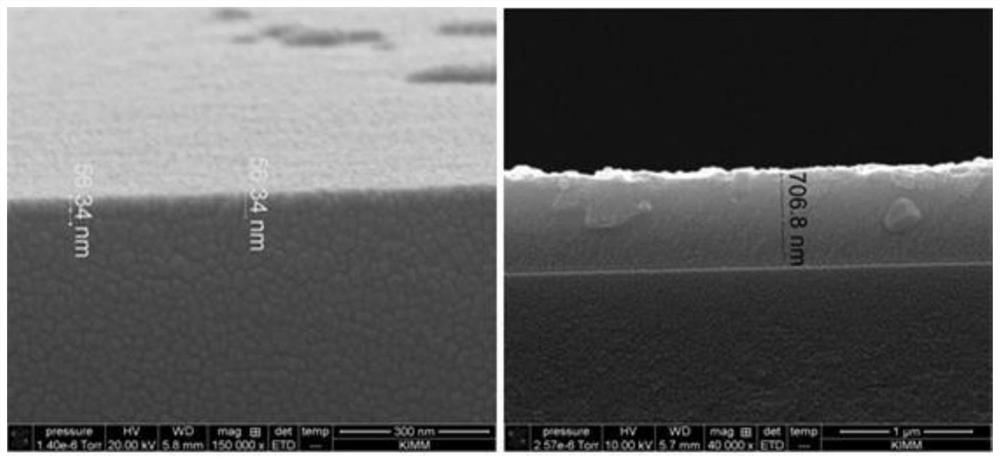

[0057] In order to prepare 200g of nano-inorganic composition, as shown in Preparation Example 4, uniformly mix ySiO 2 : 0.105 mol and X(x 1 +x 2 +x 3 ) M 2 O: 0.027 mol, making x respectively 1 : 33.8%, x 2 : 33.8%, x 3 : 26.5% percentage, or use silicon dioxide (SiO2) in sodium silicate, potassium silicate, lithium silicate respectively 2 ) is uniformly prepared so that the above-mentioned molar percentage is obtained, and the first composition is prepared by controlling the molar ratio (y / x) of the solid component contained in the composition of the present invention to 3.885, and controlling the solid content to 4.04 wt%. , with 190.72g of water (H 2 O) and 1.2g of inorganic acid compound (phosphoric acid or boric acid) to prepare the second composition, by mixing the first composition and the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com