Forming process of glass plastic

A molding process and plastic technology, applied in the direction of coating, etc., can solve the problems that cannot be tightly combined, and the upper surface cannot be guaranteed to be on the same plane, so as to achieve the effect of improving the yield rate and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

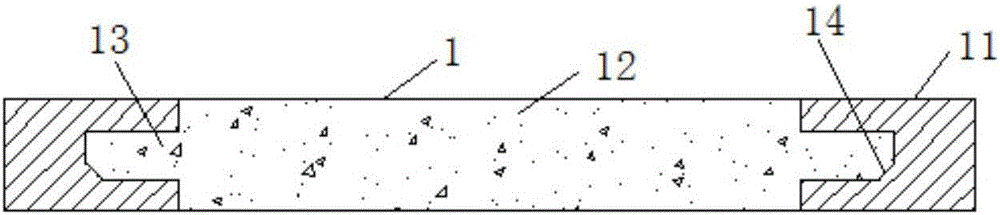

Embodiment 1

[0022] refer to figure 1 As shown, this embodiment is a molding process of glass plastics. The first step: the insert in the male template is retracted to a height of 2mm into the male template, and the glass body is placed in the groove formed by the male template and the insert, and the male and female molds are combined. When molding, the upper surface of the entry and male formwork is flush, and the push block in the mother formwork presses the glass body by 0.05mm, the height of the cavity between the mother formwork and the male formwork is consistent with the glass body, and the push block is returned to be flush with the mother formwork; The second step: injection molding on both sides of the vitreous body. The compound material of PC and 30% GF is used for injection molding.

[0023] The molding structure of glass plastic includes a glass body 1 and plastic parts 11 wrapping the outer periphery of the glass body 1 ; In this embodiment, the cross section of the body ...

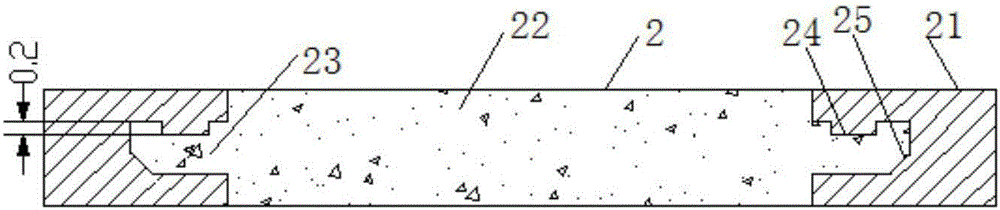

Embodiment 2

[0025] refer to figure 2 As shown, this embodiment is a molding process of glass plastics. The first step: the insert in the male template is retracted to a height of 2mm into the male template, and the glass body is placed in the groove formed by the male template and the insert, and the male and female molds are combined. When molding, the upper surface of the entry and male formwork is flush, and the push block in the mother formwork presses the glass body by 0.05mm, the height of the cavity between the mother formwork and the male formwork is consistent with the glass body, and the push block is returned to be flush with the mother formwork; The second step: injection molding on both sides of the vitreous body. The compound material of PC and 30% GF is used for injection molding.

[0026] The molding structure of glass plastic includes a glass body 2 and plastic parts 21 wrapping the outer periphery of the glass body 2 ; In this embodiment, the cross-section of the body...

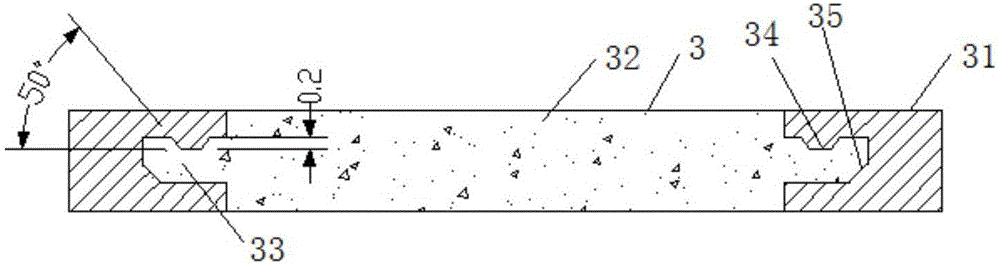

Embodiment 3

[0028] refer to image 3 As shown, this embodiment is a molding process of glass plastics. The first step: the insert in the male template is retracted to a height of 2mm into the male template, and the glass body is placed in the groove formed by the male template and the insert, and the male and female molds are combined. When molding, the upper surface of the entry and male formwork is flush, and the push block in the mother formwork presses the glass body by 0.05mm, the height of the cavity between the mother formwork and the male formwork is consistent with the glass body, and the push block is returned to be flush with the mother formwork; The second step: injection molding on both sides of the vitreous body. The compound material of PC and 30% GF is used for injection molding.

[0029] The glass plastic molding structure includes a glass body 3 and plastic parts 31 wrapping the outer periphery of the glass body 3 ; the glass body includes a body 32 and extensions 33 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com