Sediment-prevention apparatus for ink jet printer

A technology of precipitation device and stirring device, which is applied in the direction of printing, etc., can solve the problems of precipitation of ink cartridges in the pipeline head, affecting the printing effect, and long pipelines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will now be described in conjunction with the accompanying drawings.

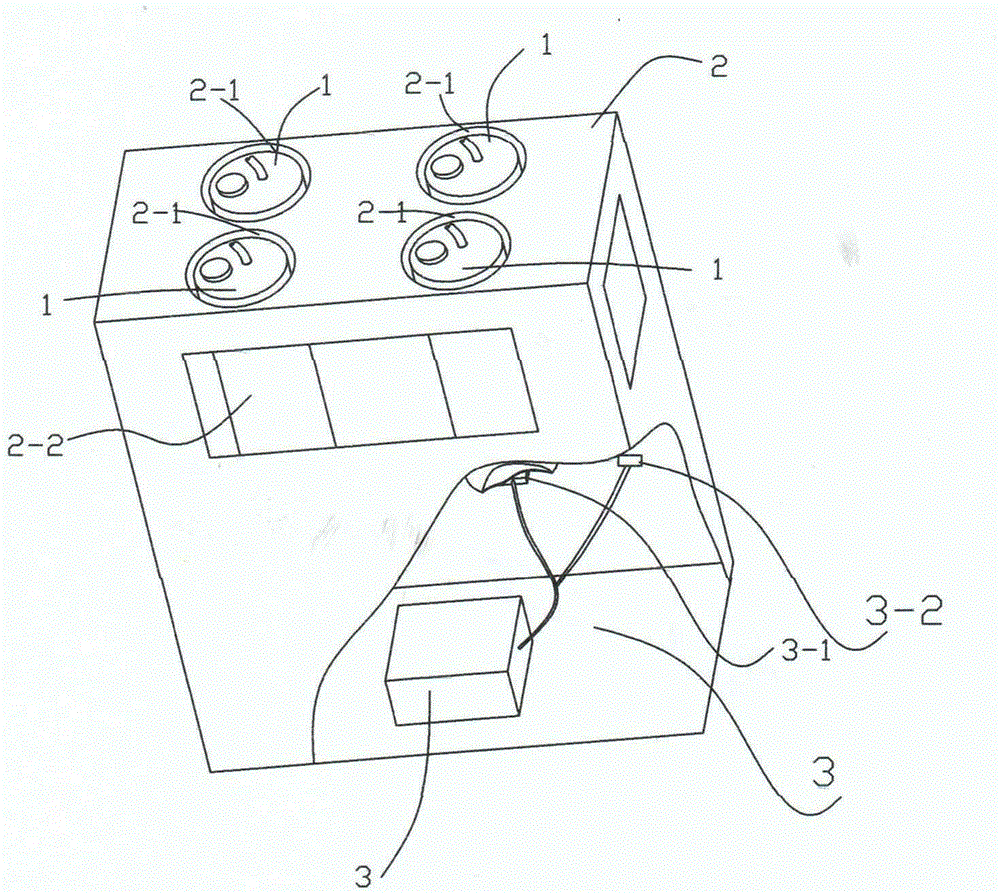

[0010] figure 1 It is a structural schematic diagram of a centralized ink supply device with a stirring device in the present invention. The present invention comprises a plurality of ink cartridges, which are used to accommodate the main body of the ink cartridge, and a stirring device. The main body is divided into upper and lower layers. device, the stirring device includes a motor, a stirring impeller and a control circuit board, the control circuit board is electrically connected to the motor, and the motor is driven to rotate the stirring impeller. like figure 1 As shown, the centralized ink supply device with vibration includes several ink cartridges 1, a body 2 and a stirring device 3 for accommodating the ink cartridges, the body is divided into upper and lower layers, and the upper layer of the body is provided with several A space 2-1 for accommodati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com