Electrified railway unmanned inspection vehicle

A technology for electrified railways and inspection vehicles, which is applied in railway car body parts, transport passenger cars, lifting devices, etc., can solve problems such as threats to the safety of maintenance personnel, inapplicability to small and medium-sized enterprises, and high cost, and achieve equipment performance. Safe and reliable, eliminate the risk of electric shock, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

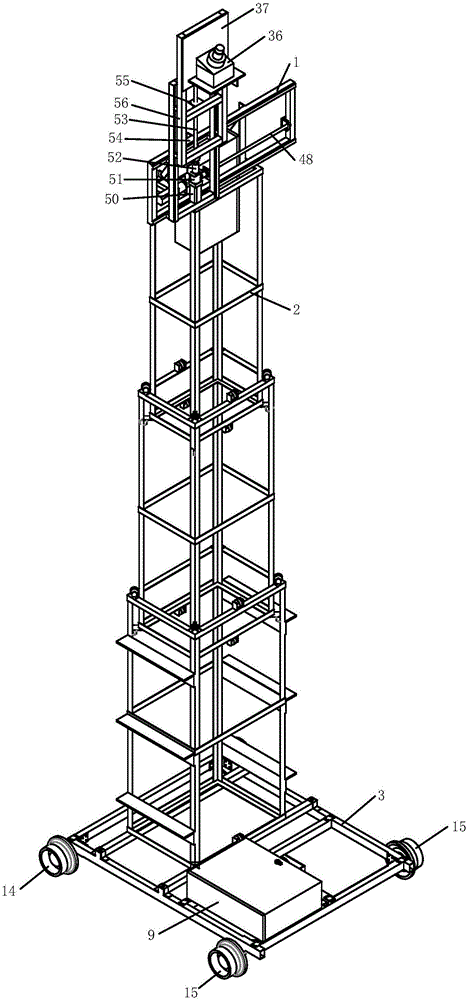

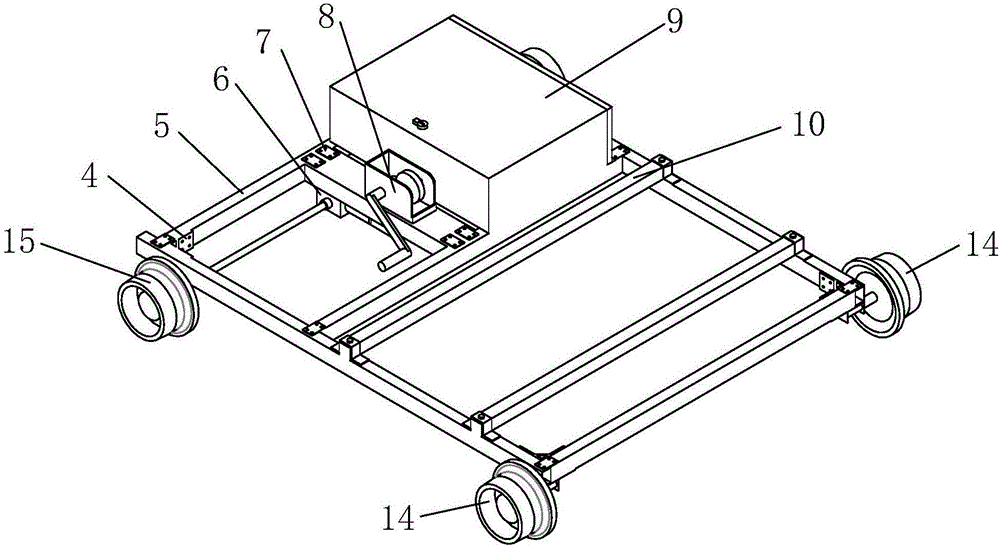

[0015] Such as figure 1 As shown, an unmanned inspection vehicle for electrified railways includes a chassis system 3 for walking on rails, a lifting mechanism 2 for lifting at vertical heights, and a mobile for taking pictures of catenary systems Platform system 1; the chassis system 3 includes a chassis frame 5 on which a drive system 6 and a first control cabinet 9 are installed; the lifting mechanism 2 includes an outer frame 24, a middle frame 23 and an inner frame 22; the lifting mechanism 2 The lower end of the lifting mechanism 2 is installed on the chassis frame 5, and the upper end of the lifting mechanism 2 is installed with a mobile platform system 1. An industrial camera 36 and a second control cabinet 45 are installed on the mobile platform system 1. Inside the second control cabinet 45 Set up the wireless transmitter.

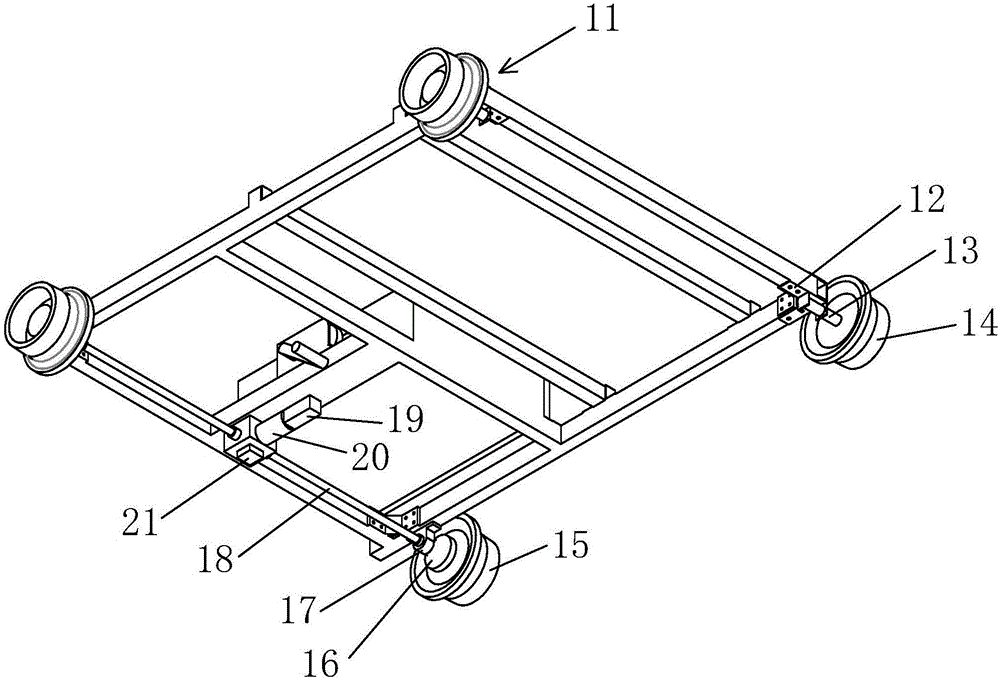

[0016] Such as figure 2 , 3 As shown, the chassis frame 5 is spliced by aluminum square tubes, and the aluminum square tubes are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com