Automatic fruit net covering device

A fruit and netting technology, applied in the direction of packaging fruits/vegetables, packaging, packaging food, etc., can solve the problems of low production efficiency, occupation of labor, low economic benefits, etc., to improve packaging efficiency, liberate productivity, and improve transportation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

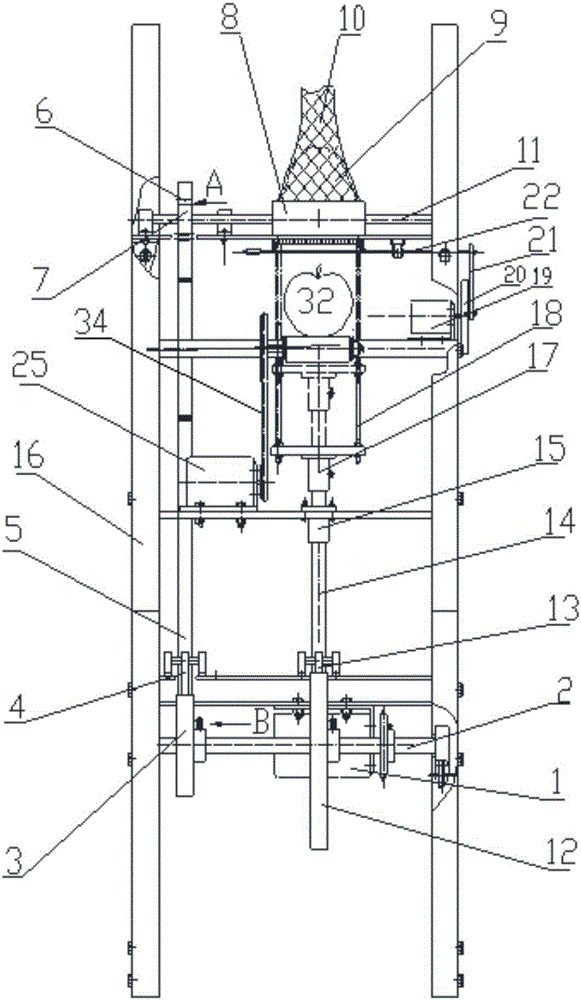

[0035] An automatic fruit netting device of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

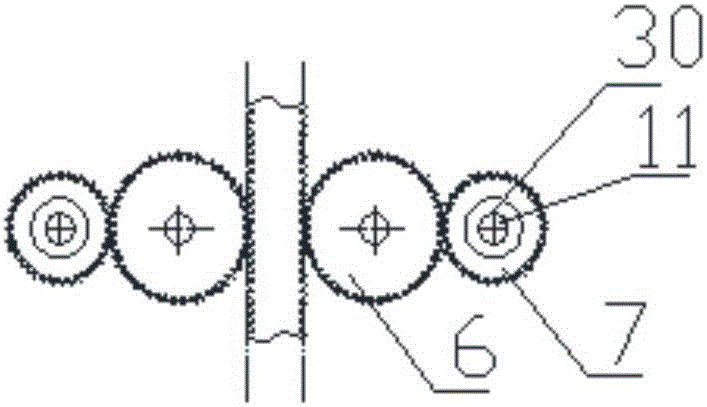

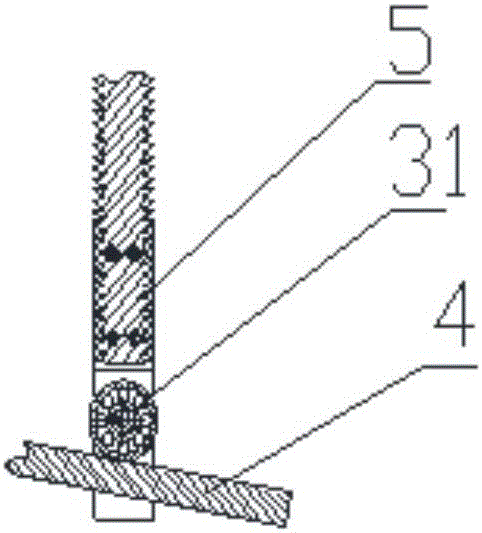

[0036] Such as figure 1 , Figure 4 Shown, a kind of automatic fruit netting device of the present invention comprises frame 16, and the upper part of frame 16 is provided with the net cover 10 that is used to wrap fruit 32 and is used to support net cover 10 at the net cover 10 ports. Cone cylinder 9, the conveyor belt 33 that horizontally runs through the upper part of frame 16 and is positioned at net cover 10 and below cone cylinder 9 is used to convey fruit 32, and the lower part of frame 16 is provided with first motor 1, and passes conveyor belt and the first motor 1 A main transmission shaft 2 connected to the output shaft of a motor 1, a vertical drive mechanism that is connected to the main transmission shaft 2 and is used to cover the net cover 10 on the fruit 32 is arranged in the frame 16 along the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com