Self-sealing liquid metal pen and method of making the same

A liquid metal, self-encapsulating technology, used in non-moving pencils, printing, writing utensils, etc., can solve problems such as poor compatibility, and achieve the effect of preventing oxidation and simplifying the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 The making of self-encapsulated liquid metal pen

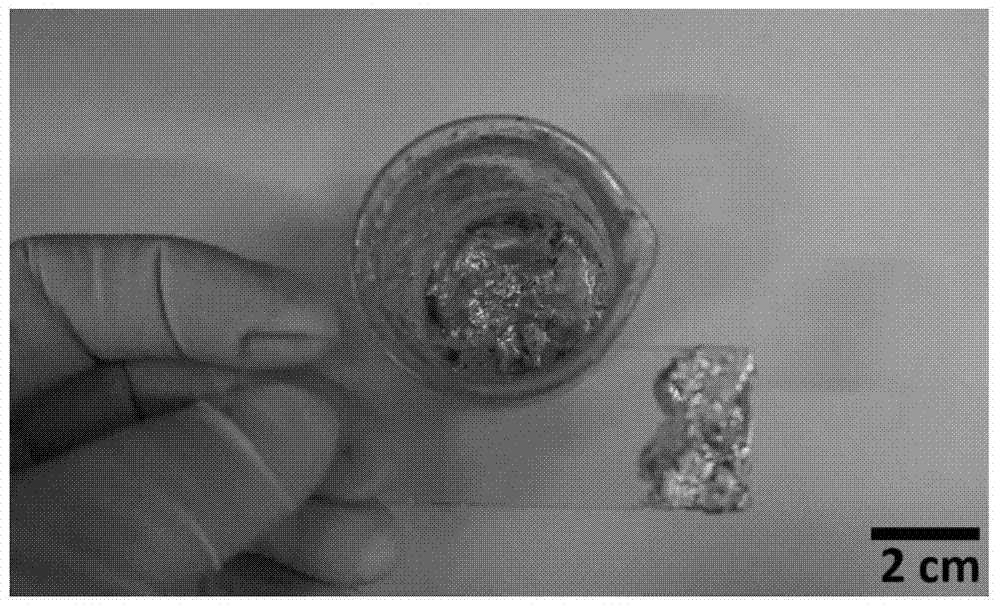

[0023] 1. Take 20ml of liquid metal (the mass percentage of gallium is 75.5%, and the mass percentage of indium is 24.5%) and put it into a beaker, stir it by magnetic force for 3-6 hours, and the stirring speed is 500r / min, so that the liquid metal is partially oxidized, from The fluid state turns into paste, and its viscosity is about 578Pa.s.

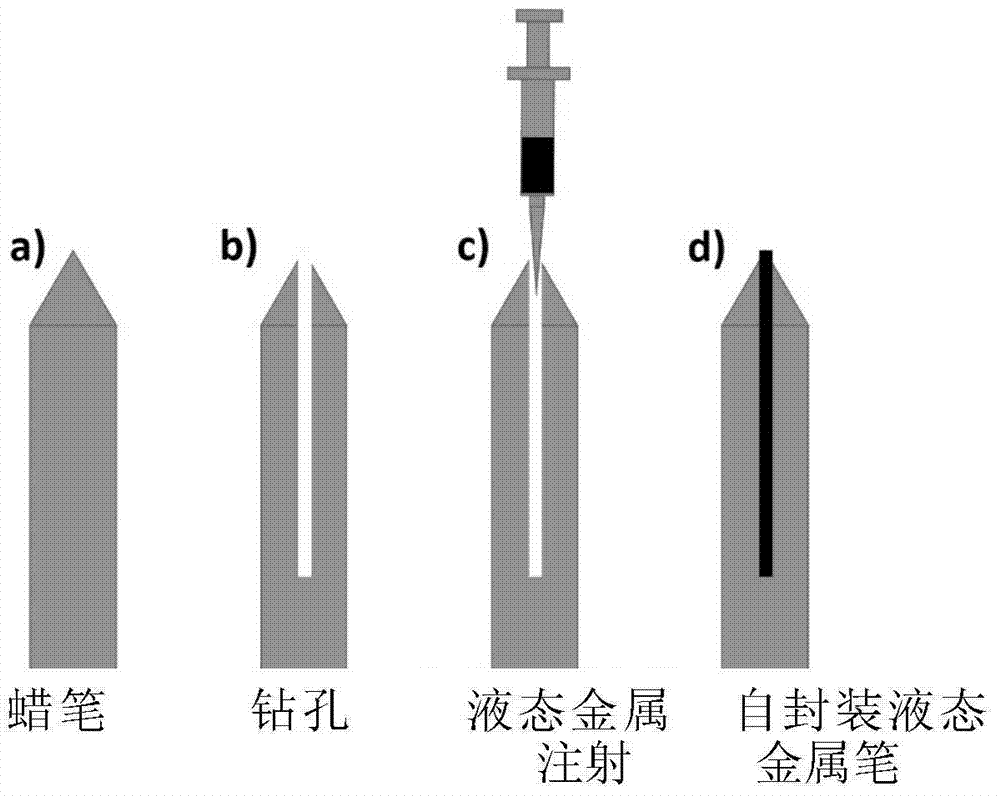

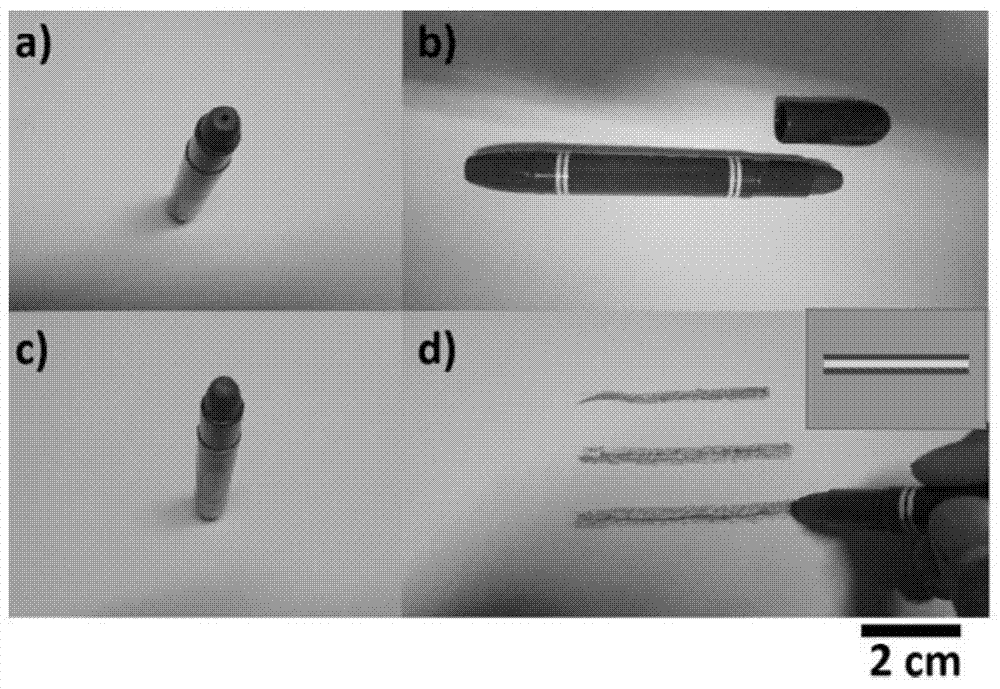

[0024] 2. Take a crayon and open the middle of it with an electric drill to prepare for filling the liquid metal.

[0025] 3. Using the pouring method, the paste-like liquid metal is injected into the center of the crayon through a syringe to form a self-encapsulated liquid metal pen.

[0026] 4. By writing on the surface of the paper, the liquid metal is in the middle of the trace left by the crayon, which effectively prevents further oxidation of the liquid metal, thus realizing encapsulation while writing.

[0027] figure 1 It is the schematic diagram of pas...

Embodiment 2

[0030] Embodiment 2 The making of self-encapsulated liquid metal pen

[0031] 1. Take 20ml of liquid metal (the mass percentage of gallium is 75.5%, the mass percentage of indium is 19.5%, and the mass percentage of tin is 5%), put it into a beaker, stir it by magnetic force for 3-6 hours, and the stirring speed is 400r / min. Partially oxidize the liquid metal and transform it from a fluid state to a paste with a viscosity of about 525Pa.s.

[0032] 2. Take a crayon and open the middle of it with an electric drill to prepare for filling the liquid metal.

[0033] 3. Through the syringe, inject the paste-like liquid metal into the center of the crayon to form a self-encapsulated liquid metal pen.

[0034] 4. By writing on the surface of the paper, the liquid metal is in the middle of the trace left by the crayon, which effectively prevents further oxidation of the liquid metal, thus realizing encapsulation while writing.

Embodiment 3

[0035] Embodiment 3 The making of self-encapsulated liquid metal pen

[0036] 1. Take 20ml of liquid metal (the mass percentage of bismuth is 75%, the mass percentage of indium is 24%, and the mass percentage of tin is 1%), put it into a beaker, stir it by magnetic force for 3-6 hours, and the stirring speed is 200r / min , to partially oxidize the liquid metal and transform it from a fluid state to a paste, with a viscosity of about 600Pa.s.

[0037] 2. Take a candle and heat it to make it into a viscous substance to prepare for the production of the self-encapsulating liquid metal pen.

[0038] 3. Extrude the pasty liquid metal into a column shape through the extrusion and heating device, and then press the liquid wax into a groove shape, place the liquid metal in the middle, and compact it at 80°C to form a self-encapsulated liquid metal pen ( Figure 4 ).

[0039] 4. By writing on the surface of the paper, the liquid metal is in the middle of the trace left by the crayon, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com