Polyester woven label and preparation method thereof

A polyester weaving label and weft yarn technology is applied in the field of clothing accessories and can solve the problems of labor-intensive and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

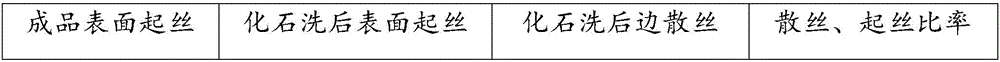

Examples

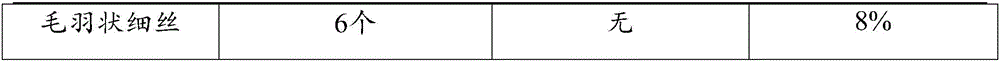

Embodiment 1

[0043] A kind of preparation method of polyester woven label of the present embodiment comprises the following steps:

[0044] (1) Treatment of weft yarn

[0045] Pretreatment of the weft yarn, followed by alkali weight reduction and antistatic finishing;

[0046] 50D, 75D, 100D polyester weft yarns are pretreated, the process parameters are: 90°C-100°C, 20min-60min, liquor ratio 1:8-20.

[0047] It is then pretreated with alkali reduction and permanent antistatic treatment. Alkali reduction treatment conditions: caustic soda 5-10 g / L, alkali reduction accelerator (FN, purchased from Guangdong Demei Chemical) 0.5-1.0 g / L, 90-100°C, treatment for 30-60 minutes, liquor ratio 1 : 8~20; Drain and refill, add degreasing agent LCF-185 (purchased from Fuying Technology Chemical Co., Ltd.) 0.5 ~ 1.0 g / L, dispersant IS (purchased from Tuona Trading (Shanghai) Co., Ltd.) 0.5 ~1.0g / L, 60~70℃, treatment for 30~60 minutes; Drainage, water inflow, add acetic acid 3.0g / liter, 50~60℃, trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com