Hollow double-arc-shaped large window frame limestone powder line

A window covering line and arc technology, applied in the field of double-arc large window covering stone powder line, can solve the problems of color difference affecting beauty, high price, easy to fall off and not resistant to water immersion, etc. Abrasive and imitative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

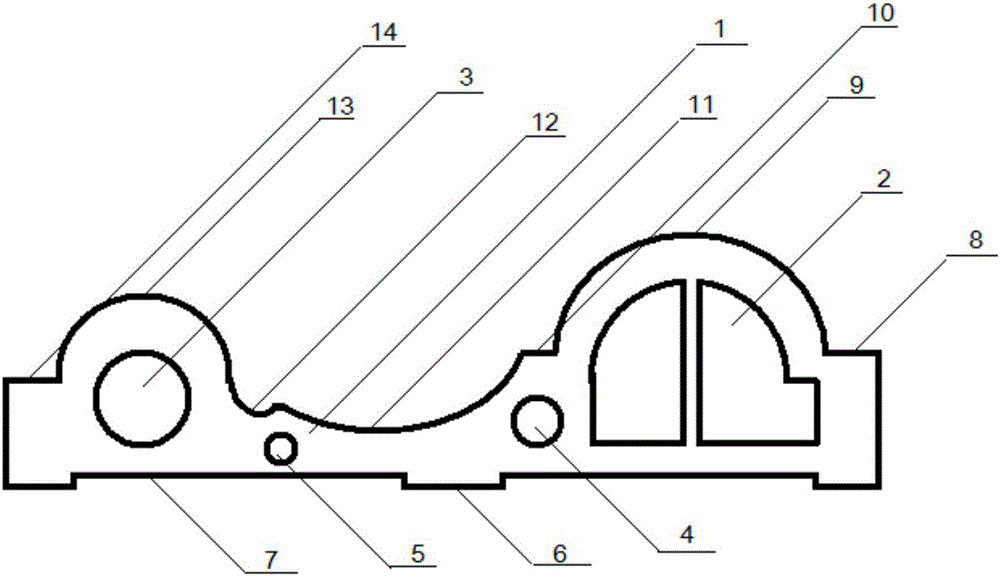

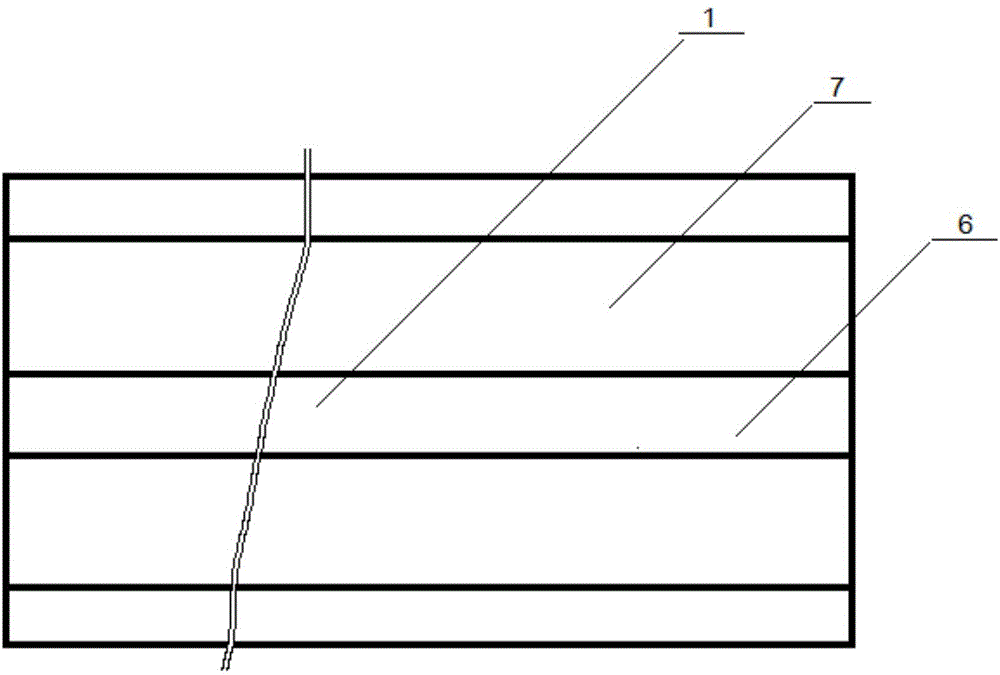

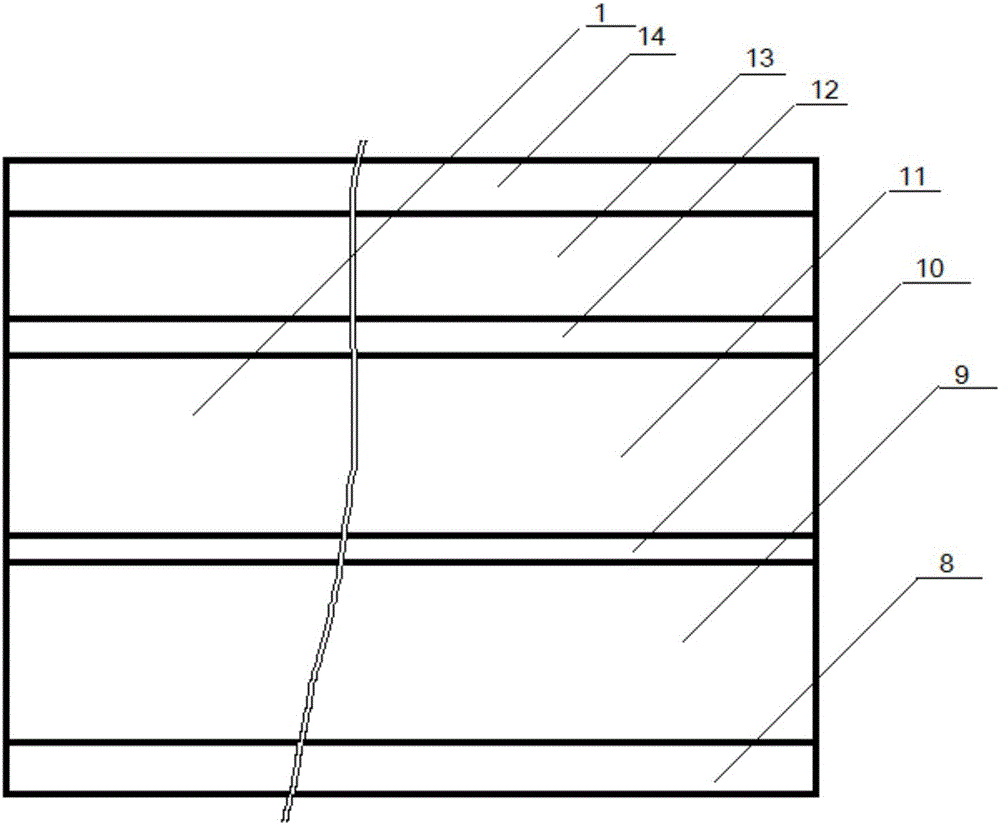

[0017] Embodiment 1: A hollow double-arc large window cover stone powder line, the window cover line body 1 is an elongated strip shaped by pressing stone powder, and the cross-sectional shape of the window cover line body 1 is a double arc shape on the upper side and a rectangular shape on the lower part The bottom surface 6 at the bottom of the window casing body 1 is provided with a storage tank 7 for storing adhesive; the inside of the window casing body 1 is provided with holes for heat insulation and material saving; To the left, the right platform 8, the large arc protrusion 9, the middle platform 10, the large concave arc 11, the small concave arc 12, the small arc protrusion 13 and the left platform 14; The corresponding place under 9 is provided with two right large holes 2, the corresponding place under middle platform 10 is provided with the middle hole 4 on the right side, and the corresponding place under the small concave arc 12 is provided with the small hole 5 ...

Embodiment 2

[0018] Embodiment 2: A hollow double-arc large window cover stone powder line, the window cover line body 1 is an elongated shape pressed by stone powder, and the cross-sectional shape of the window cover line body 1 is a double arc shape on the upper side and a rectangular shape on the lower part The bottom surface 6 at the bottom of the window casing body 1 is provided with a storage tank 7 for storing adhesive; the inside of the window casing body 1 is provided with holes for heat insulation and material saving; To the left, the right platform 8, the large arc protrusion 9, the middle platform 10, the large concave arc 11, the small concave arc 12, the small arc protrusion 13 and the left platform 14; The corresponding place under 9 is provided with two right large holes 2, the corresponding place under middle platform 10 is provided with the middle hole 4 on the right side, and the corresponding place under the small concave arc 12 is provided with the small hole 5 on the l...

Embodiment 3

[0019] Embodiment 3: A hollow double-arc large window cover stone powder line, the window cover line body 1 is an elongated shape pressed by stone powder, and the cross-sectional shape of the window cover line body 1 is a double arc shape on the upper side and a rectangular shape on the lower part The bottom surface 6 at the bottom of the window casing body 1 is provided with a storage tank 7 for storing adhesive; the inside of the window casing body 1 is provided with holes for heat insulation and material saving; To the left, the right platform 8, the large arc protrusion 9, the middle platform 10, the large concave arc 11, the small concave arc 12, the small arc protrusion 13 and the left platform 14; The corresponding place under 9 is provided with two right large holes 2, the corresponding place under middle platform 10 is provided with the middle hole 4 on the right side, and the corresponding place under the small concave arc 12 is provided with the small hole 5 on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com