Folding and unfolding mechanism

A technology of stretching mechanism and connecting rod, which is applied in the direction of connecting components, mechanical equipment, thin plate connection, etc., can solve the problems of large occupied space, poor application, complicated mechanism, etc., and achieves easy maintenance, simple structure and simplified structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

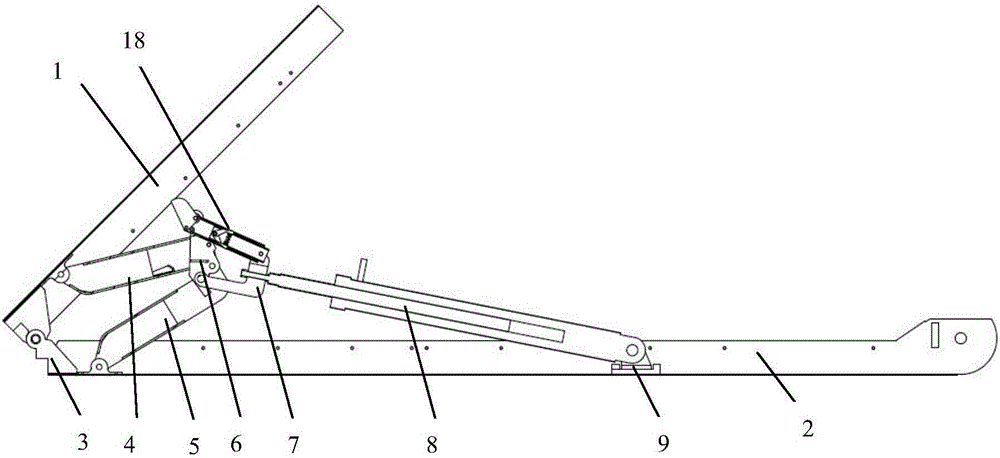

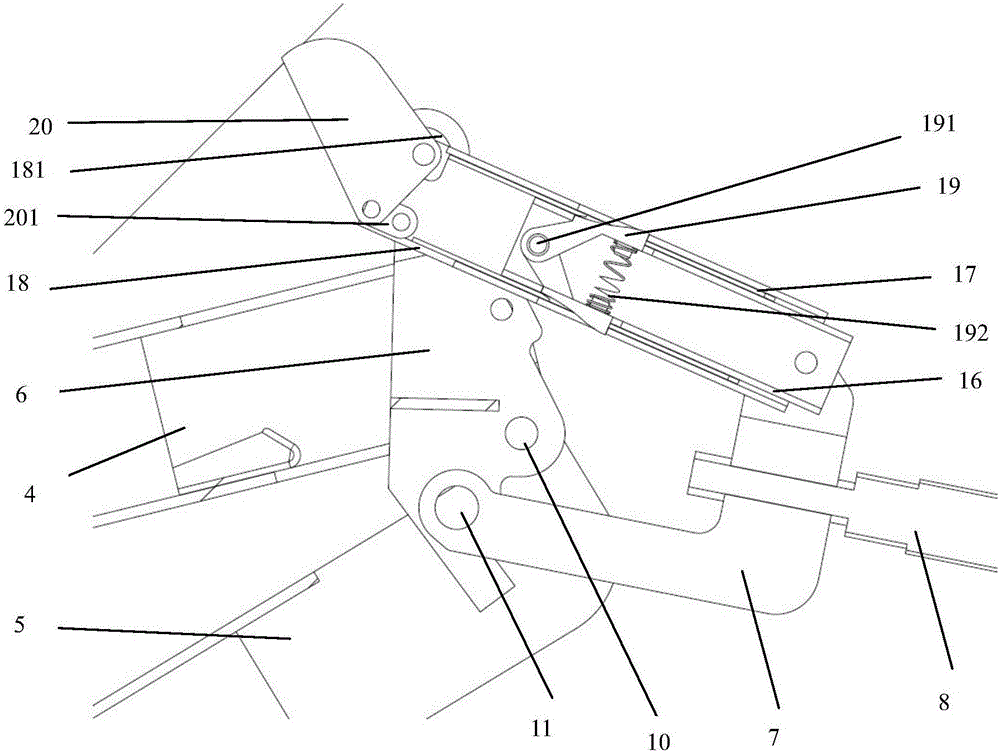

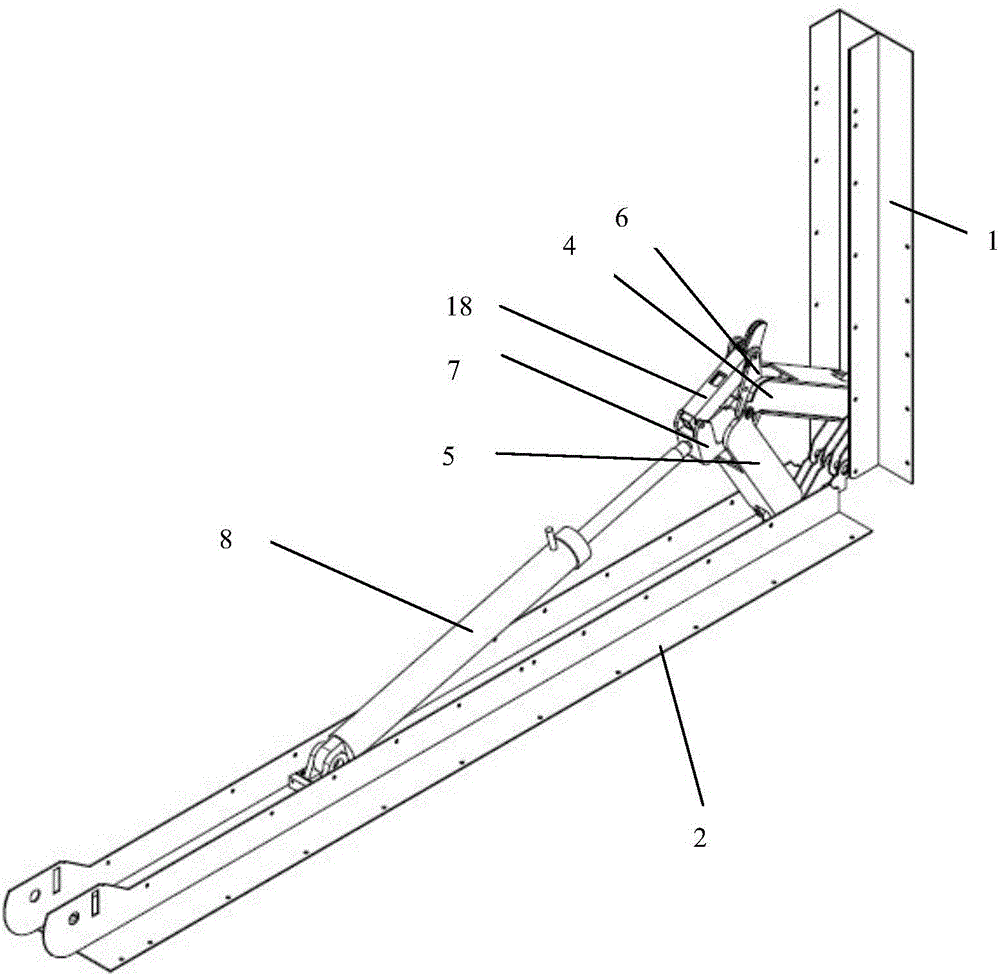

[0033] In further embodiments of the present invention, please continue to refer to figure 1 , figure 2As shown, a side of the starting skid 20 opposite to the other end of the outer sleeve 18 is provided with a circular arc surface, and the circular arc surface is facing the upper panel 1 .

[0034] In a further embodiment of the present invention, the side surface of the fourth connecting rod 7 is "L"-shaped.

[0035] In a further embodiment of the present invention, the upper panel 1 and the lower panel 2 are connected by a hinge 3 , and the upper panel 1 and the lower panel 2 can rotate relative to each other around the hinge 3 .

[0036] In a further embodiment of the present invention, the upper panel 1 and the lower panel 2 are provided with grooves on the opposite faces, and the two grooves together form an accommodating space, and the four-link assembly is stored in the accommodating space in the folded state. within the space.

[0037] In a further embodiment of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com