Pressure-carrying sealing valve seat

A technology for sealing valves and valve seats, which is applied to valve devices, cocks including cut-off devices, engine components, etc. It can solve the problems of complex process, high cost, and the inability of valves to be repaired and replaced with sealed valve seats under pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

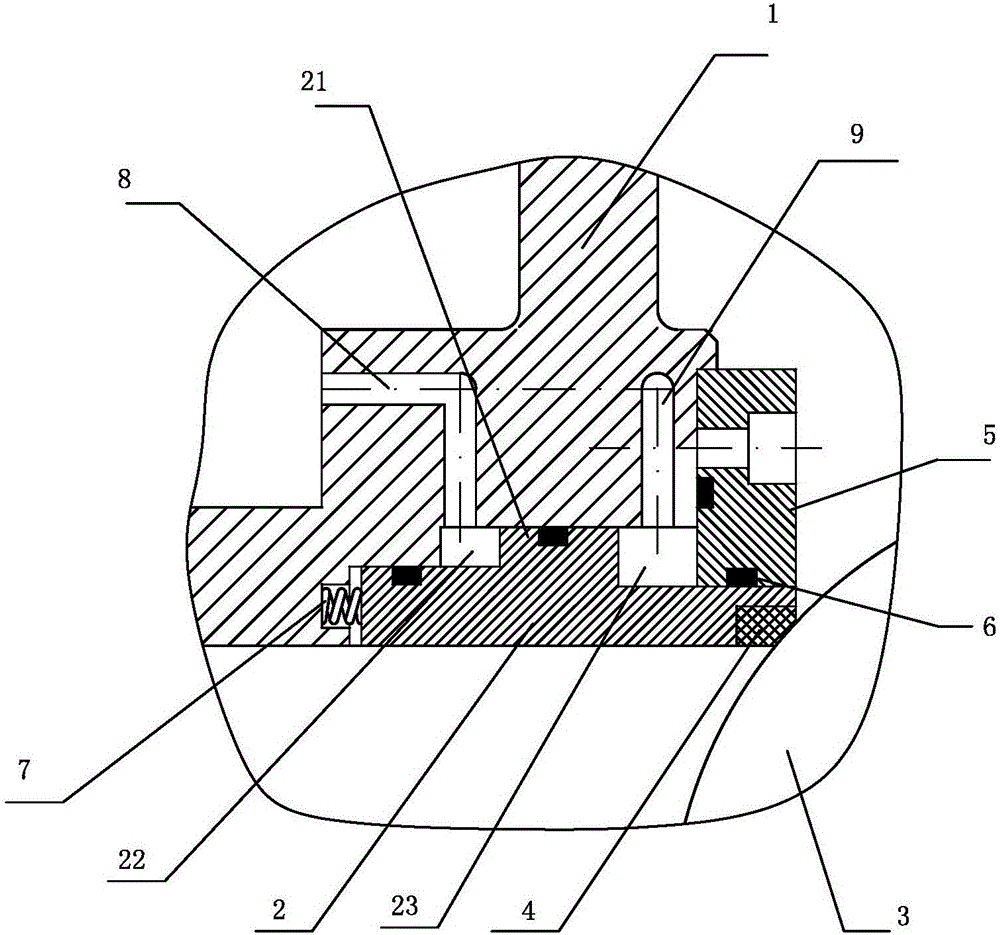

[0013] Embodiment: The present invention seals the valve seat with pressure, as attached figure 1 As shown, it includes a valve seat 2 and a ball 3 arranged in the valve body 1. The valve seat 2 has a hole, and a sealing gasket 4 forms a sealing connection between the hole and the ball 3; the valve seat 2 is slidably arranged in the axial direction. In the valve cavity of the valve body 1; the outer periphery of the valve seat 2 has an annular boss 21, and the outer peripheral surface of the valve seat 2 on both sides of the annular boss 21 and the valve body 1 are surrounded by a first cavity 22 and a second cavity 23 , and the radius of the outer peripheral surface of the valve seat 2 in the second cavity 23 is larger than the radius of the outer peripheral surface of the valve seat 2 in the first cavity 22, so as to overcome the pressure from the spring 7; The first guide hole 8 and the second guide hole 9 communicating with the second cavity 23 .

[0014] A spring 7 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com