An electric tower bottom gate valve

A gate valve, electric technology, applied in the direction of sliding valve, valve details, valve device, etc., can solve the installation and maintenance conditions of rectangular gate valve without hydraulic drive, can not fully meet the full range of installation, installation and maintenance The problem of large occupation space, etc., achieves the effect of improving the safety of the equipment site, small occupation space, and easy maintenance and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

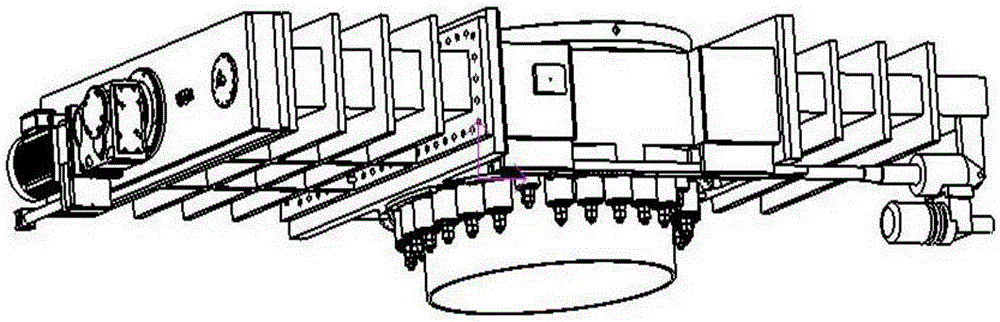

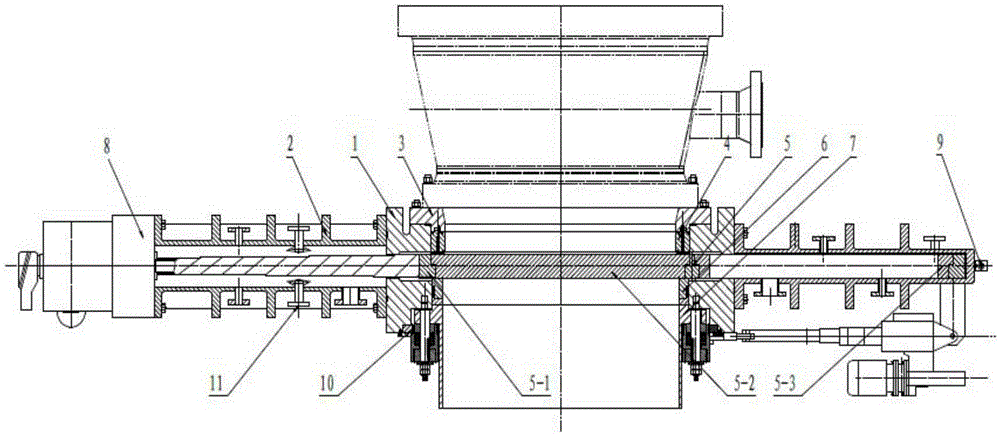

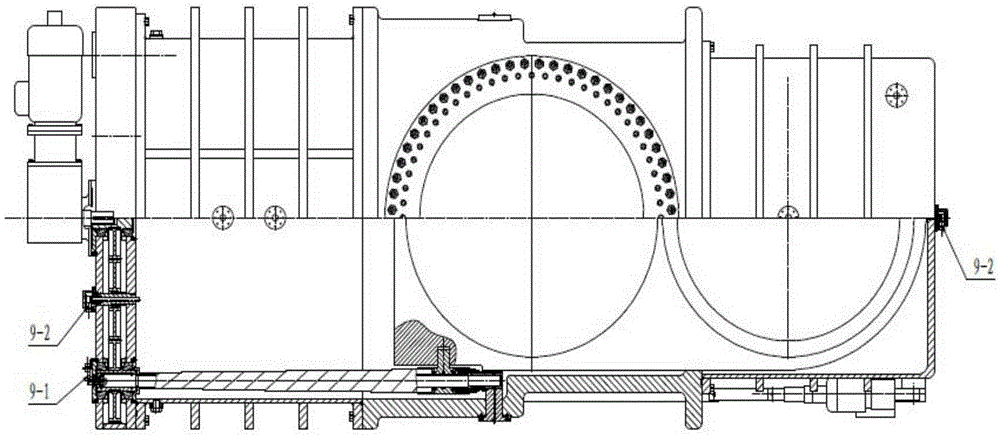

[0040] as attached figure 1 to attach Figure 8 shown.

[0041] The valve adopts all-electric operation, without hydraulic system; electric, pneumatic and manual valve opening and closing operations can be performed; the occupied space is small, which can meet the conditions for all-round installation and maintenance of the coke tower bottom space; remote control can be realized.

[0042] Such as figure 2 and 3As shown, the electric valve has a housing 1, the upper and lower ends of the housing 1 are respectively provided with through holes, an upper flange, and a lower flange, and the upper flange of the housing 1 is connected to the lower port of the upstream channel through the sealing seat 3. The through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com