Patents

Literature

37results about How to "Appropriate preload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

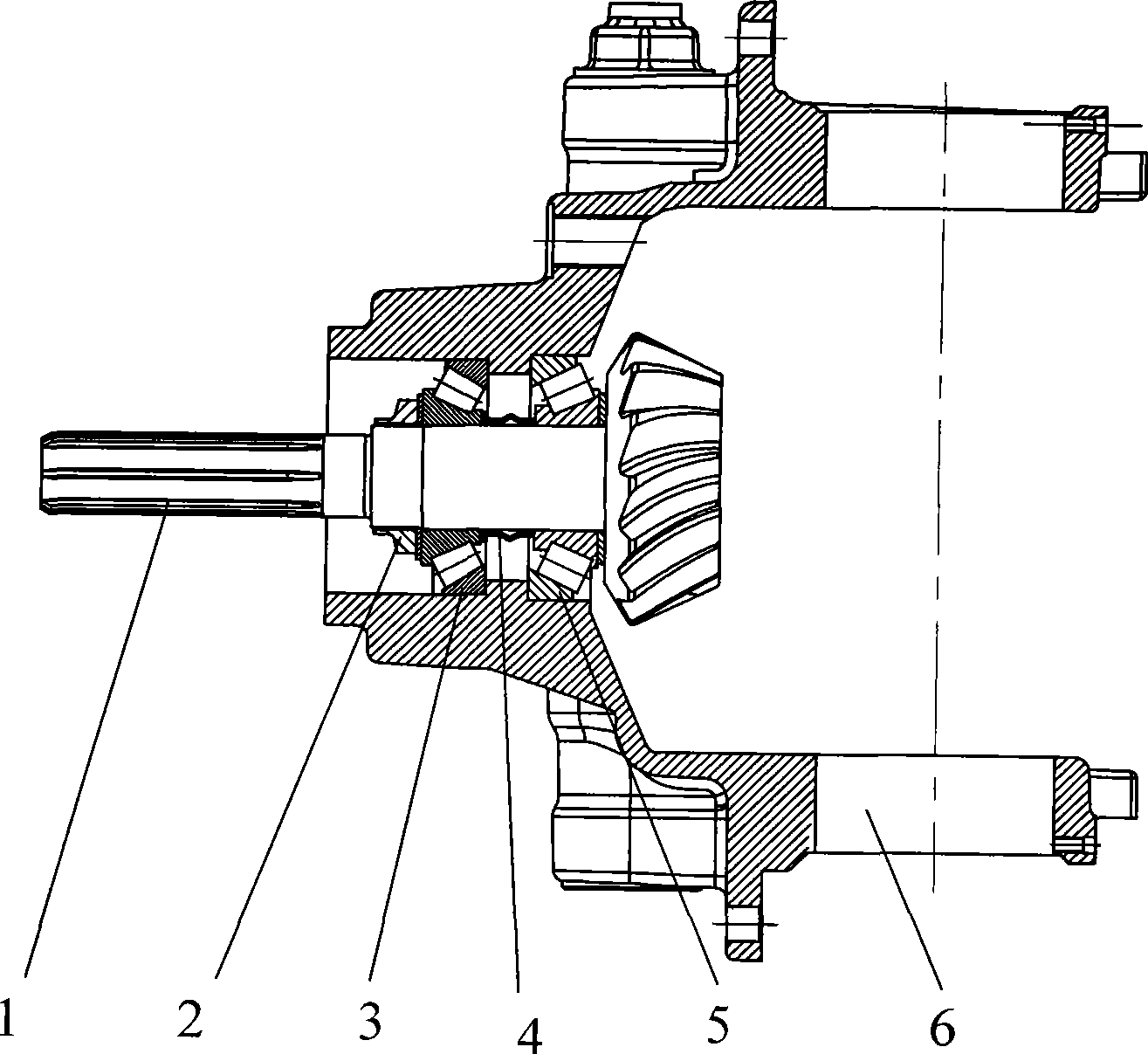

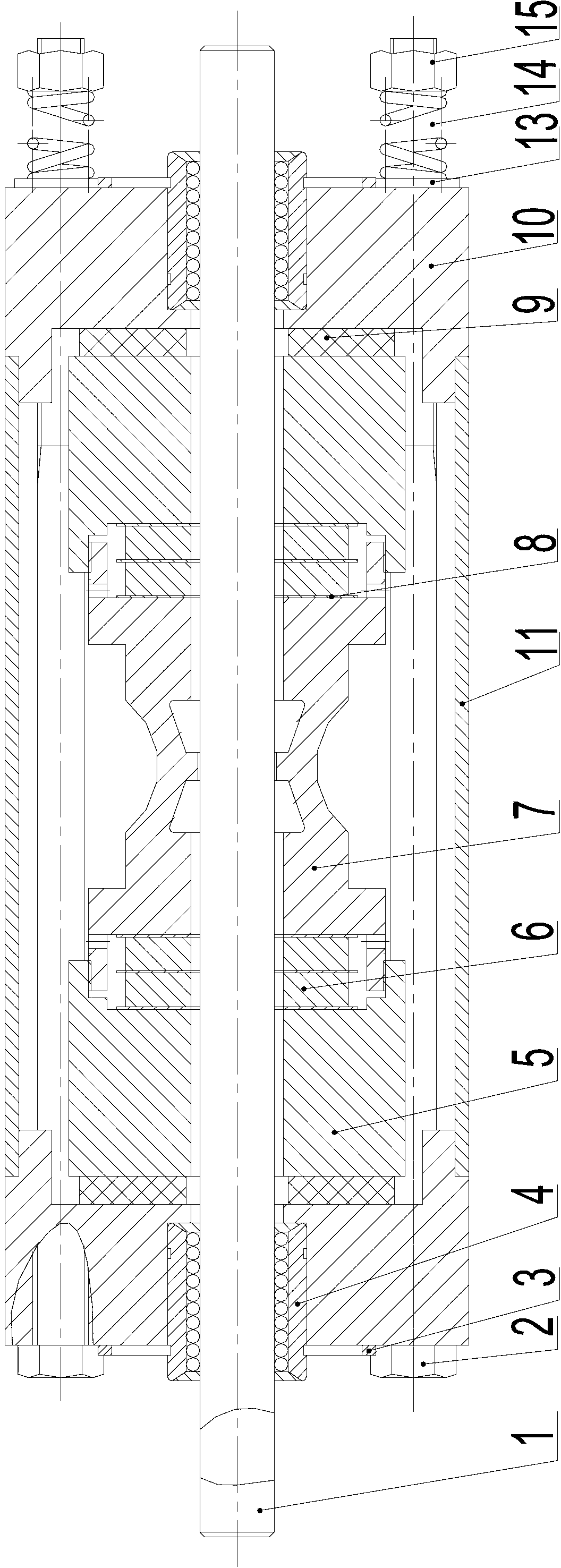

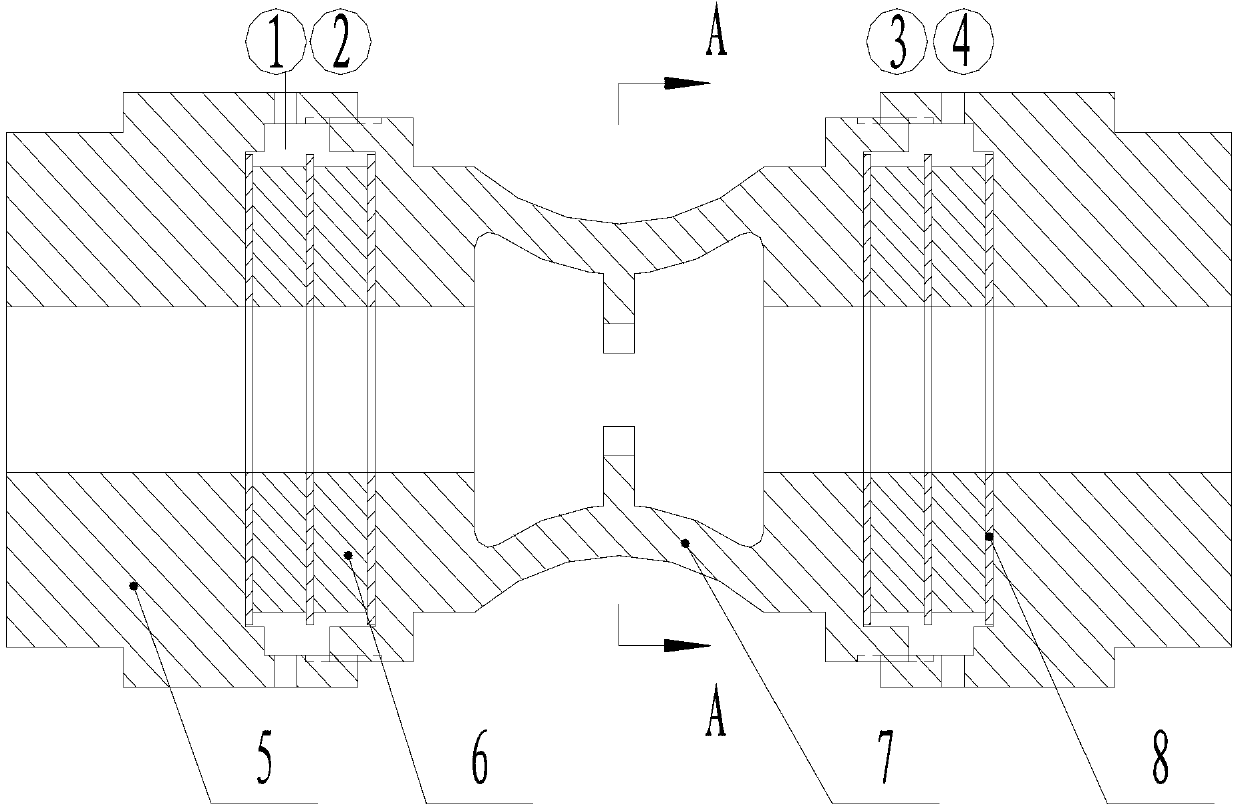

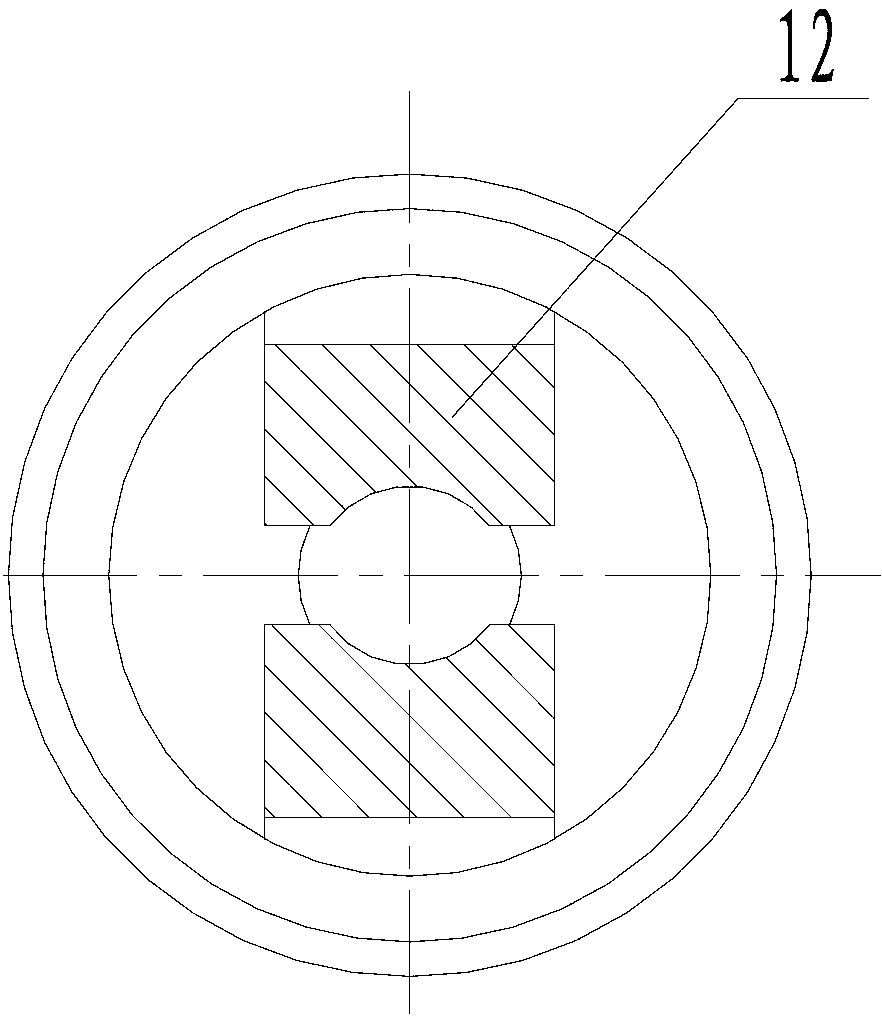

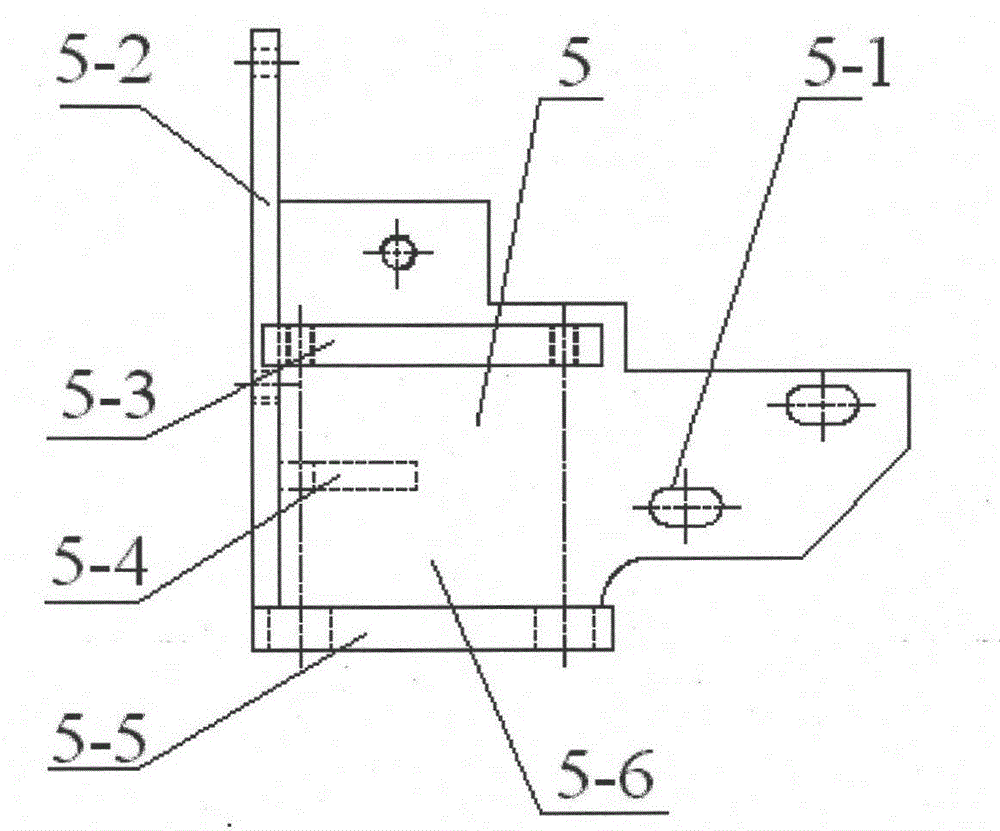

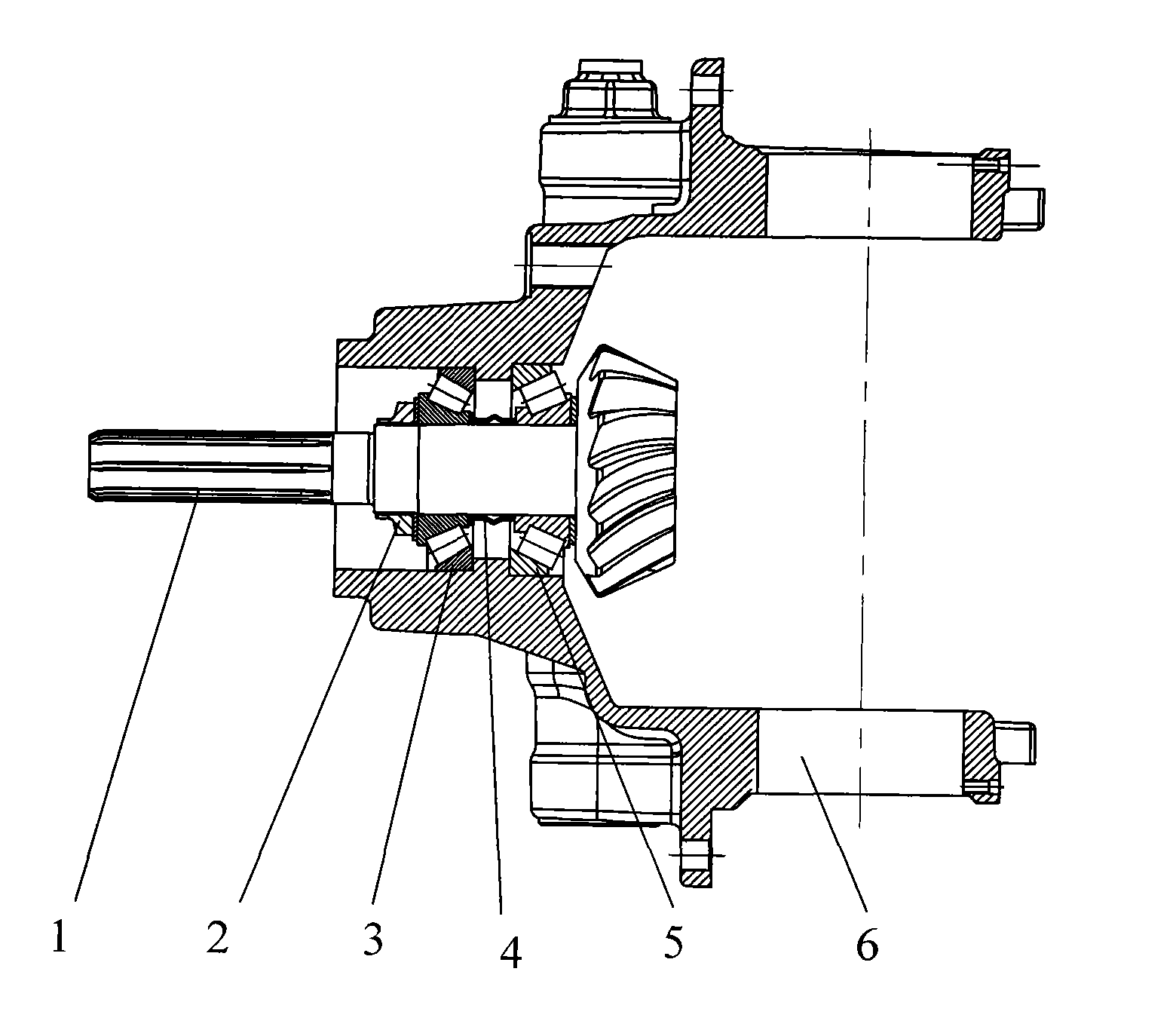

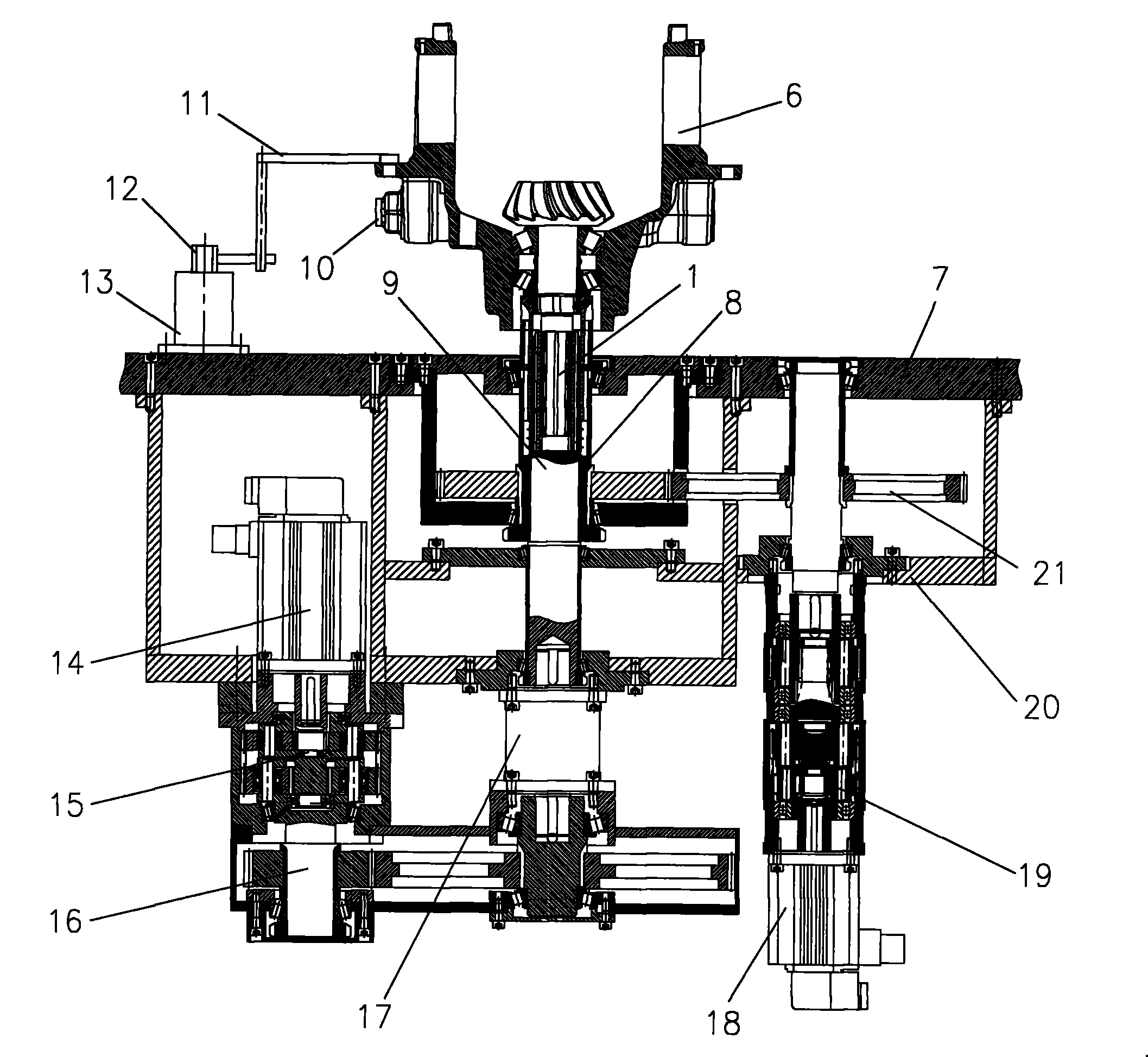

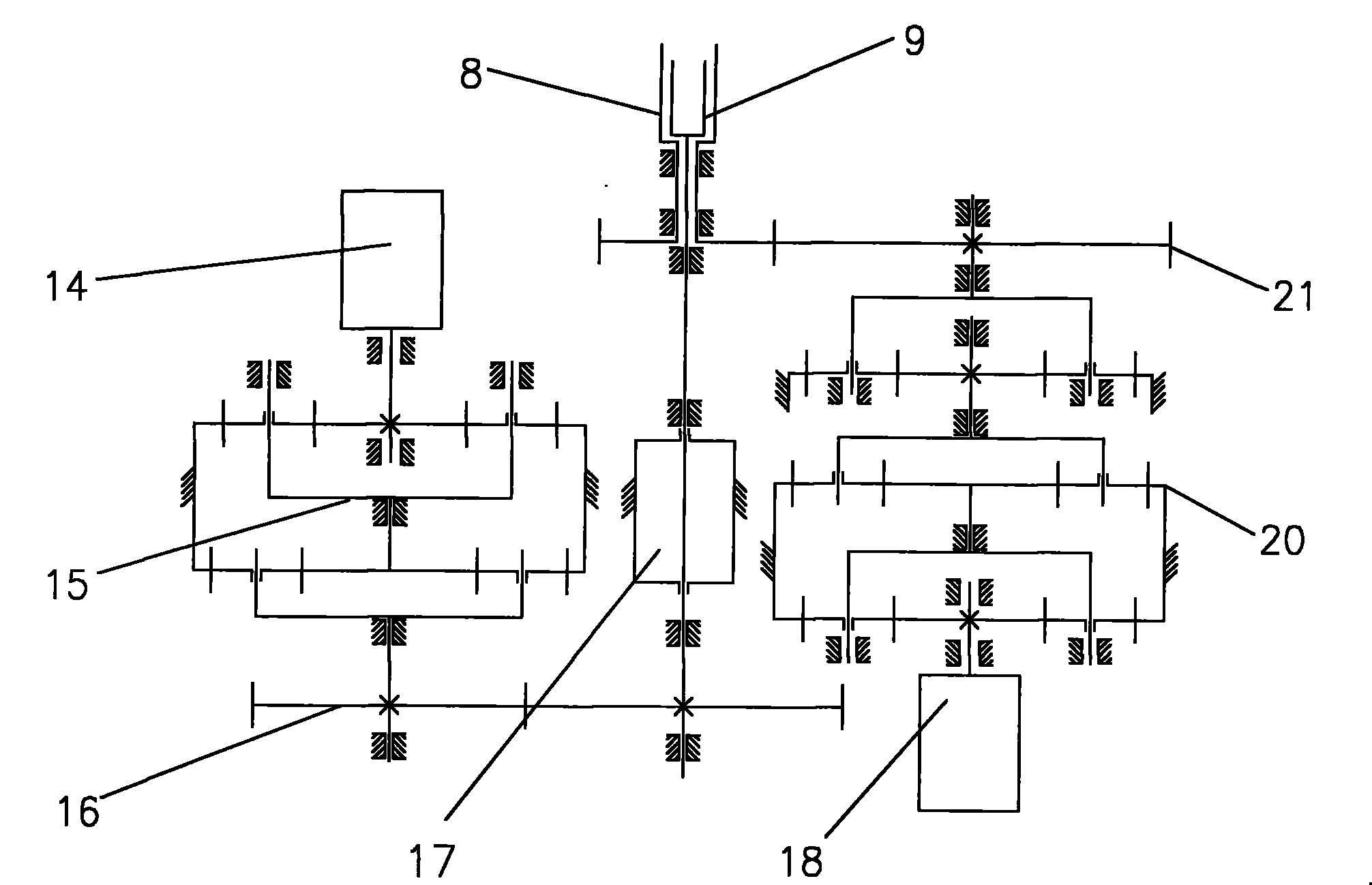

Differential screwed loader main cone pretightening force measuring set and method

InactiveCN101419106ARealize detectionAccurate measurementMeasurement of torque/twisting force while tighteningFriction torqueDifferential screw

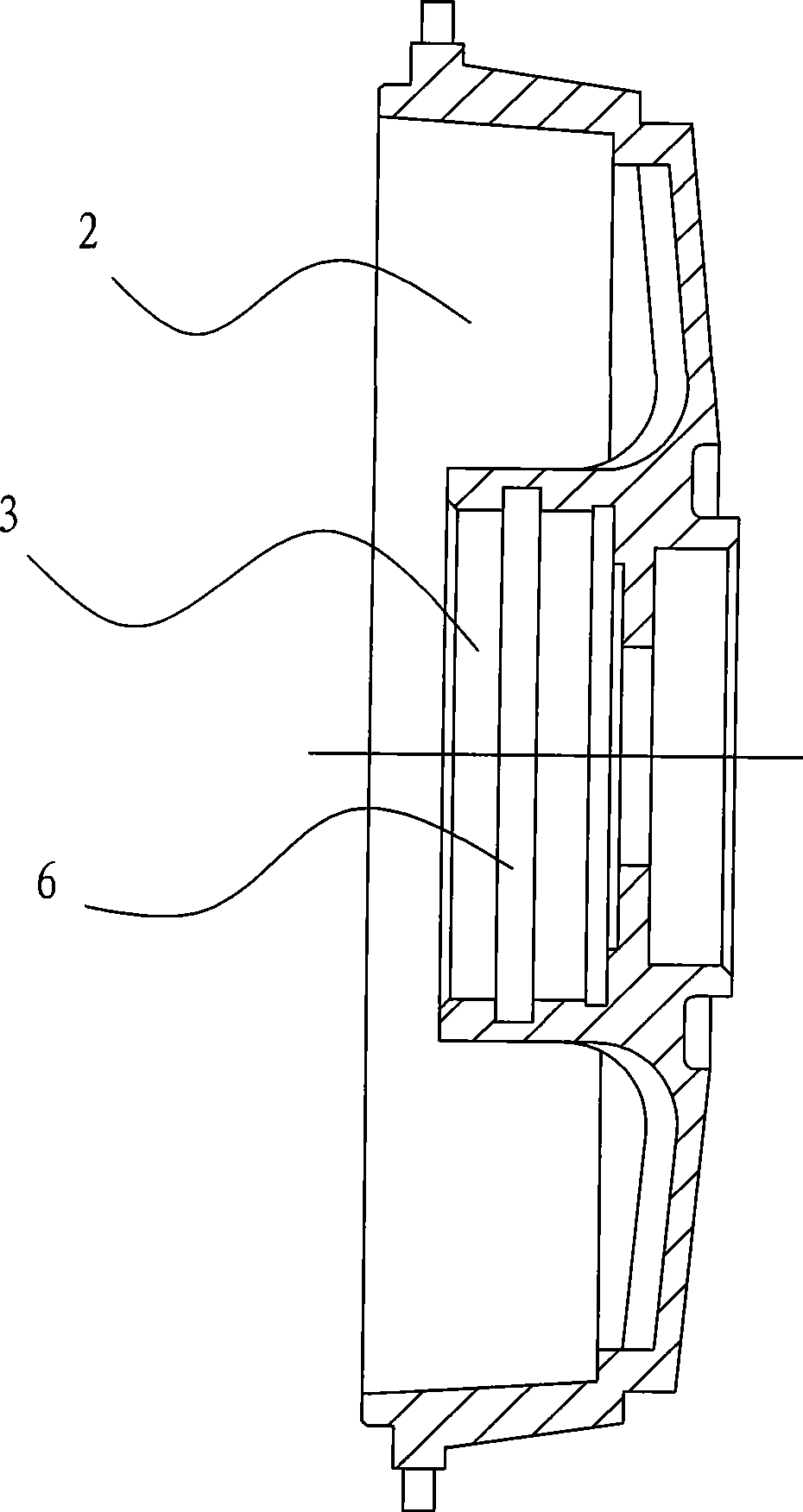

The invention relates to a device and a method for measuring the pretightening force of a main cone of a loader based on differential speed tightening, which is characterized in that the measuring device is provided with a work top, a sleeve, an inner spline, a transmission line 1, a transmission line 2, and a pretightening moment measuring mechanism, wherein the work top is taken as a preassembling bench of the main cone and a bearing pedestal and a bearing pretightening moment measuring bench; the sleeve is matched with an opening of a locknut and used for screwing up the locknut; the inner spline is matched with an outer spline on the tail of the main cone and used for driving the main cone to rotate; the transmission line 1 takes a servomotor as a driving piece and the inner spline as a driven piece; and the transmission line 2 takes a servomotor as a driving piece and a sleeve as a driven piece. The method adopts the means of differential speed tightening to well realize detection of the starting friction torque.

Owner:HEFEI UNIV OF TECH

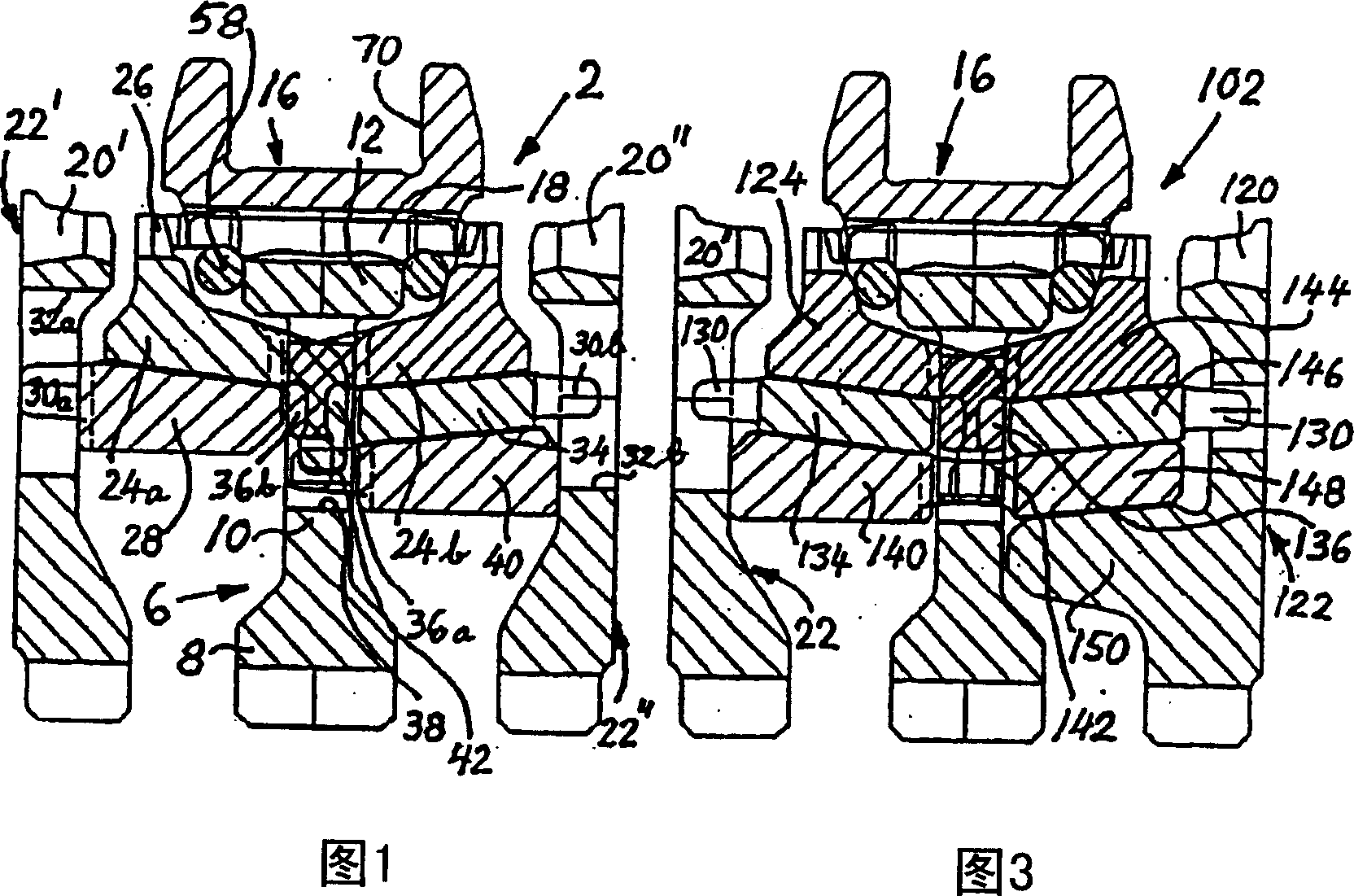

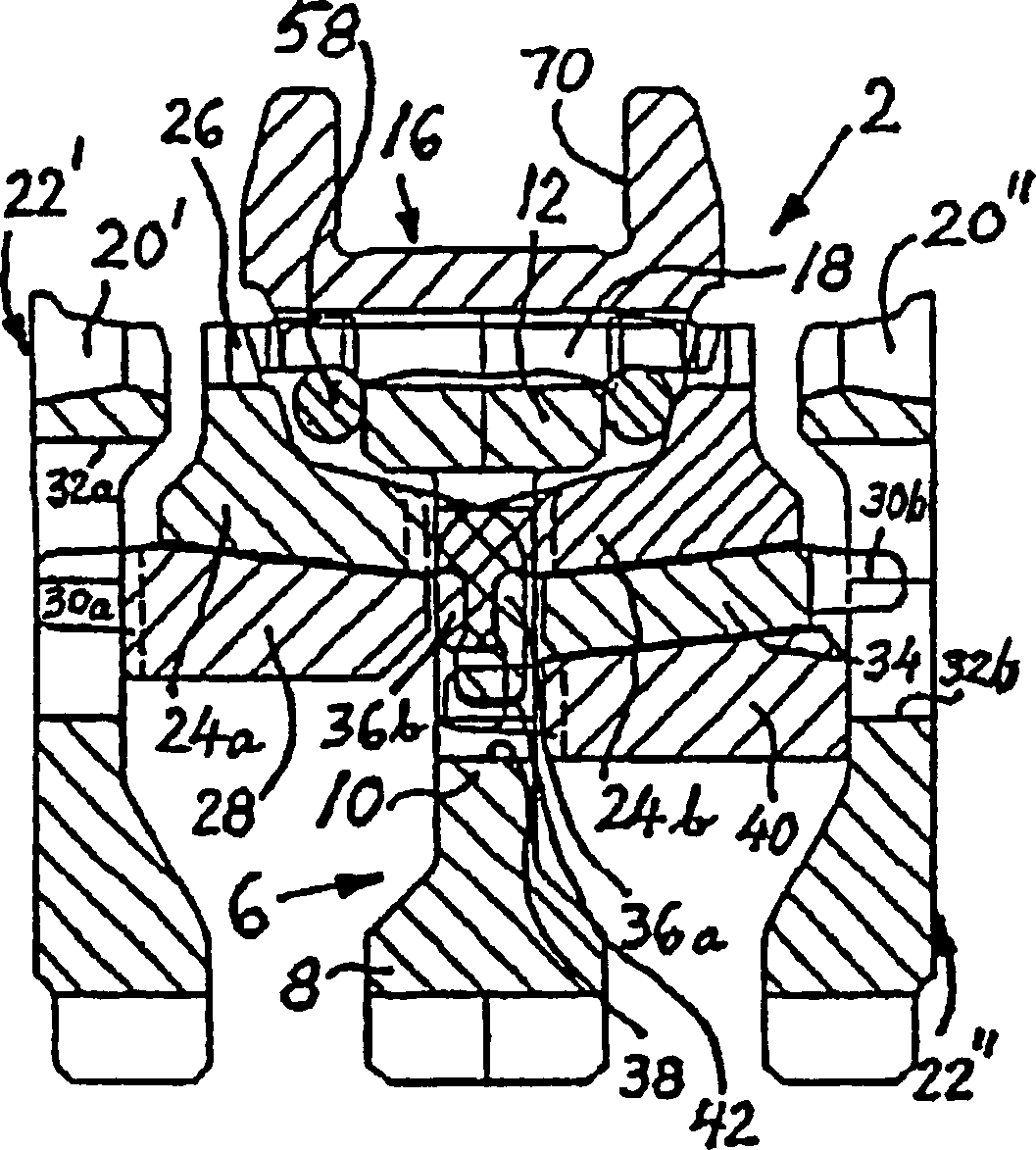

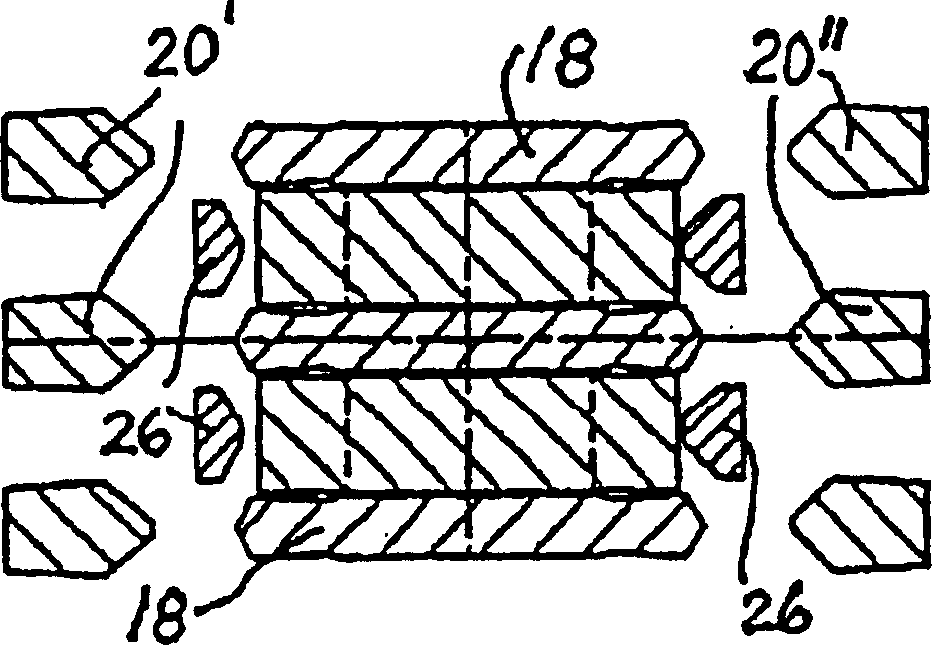

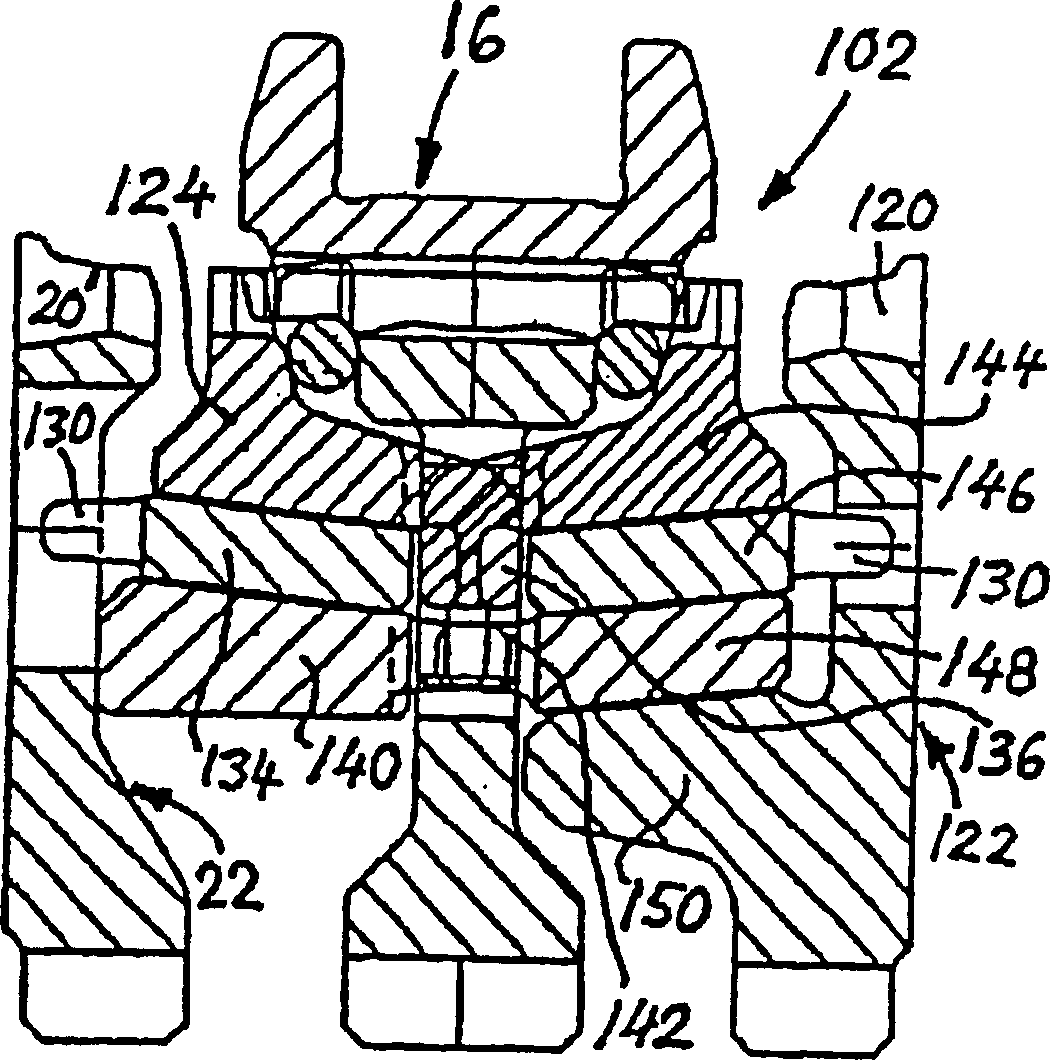

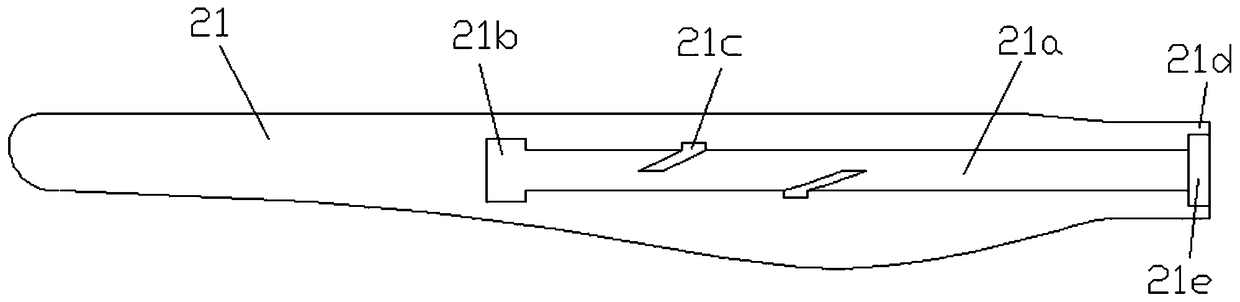

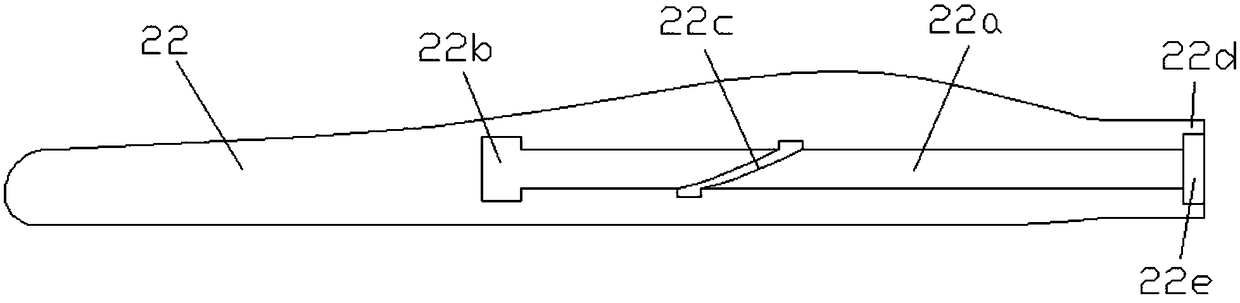

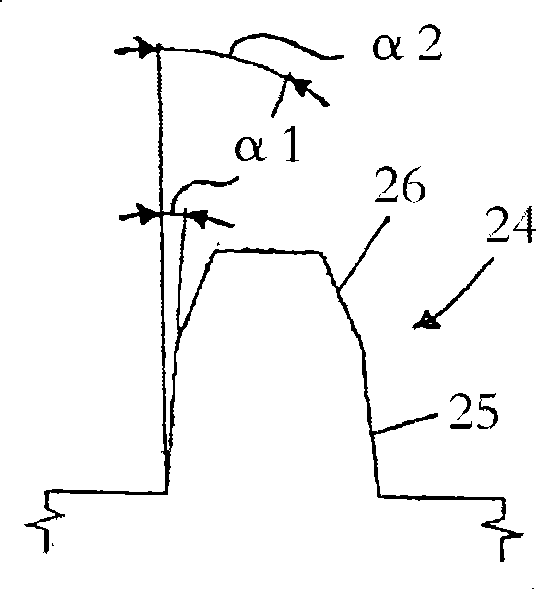

Assembly system for synchronizing devices in a gearbox

InactiveCN1604997AImprove utilizationRoughly constant spoke thicknessMechanical actuated clutchesCouplings for rigid shaftsCouplingEngineering

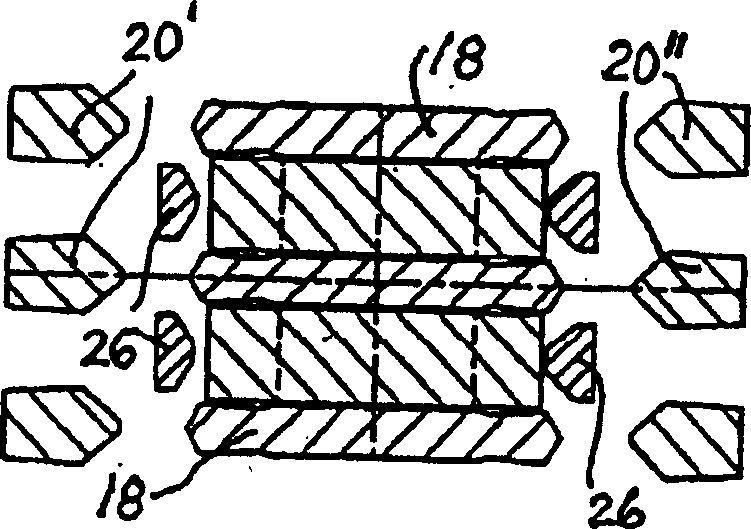

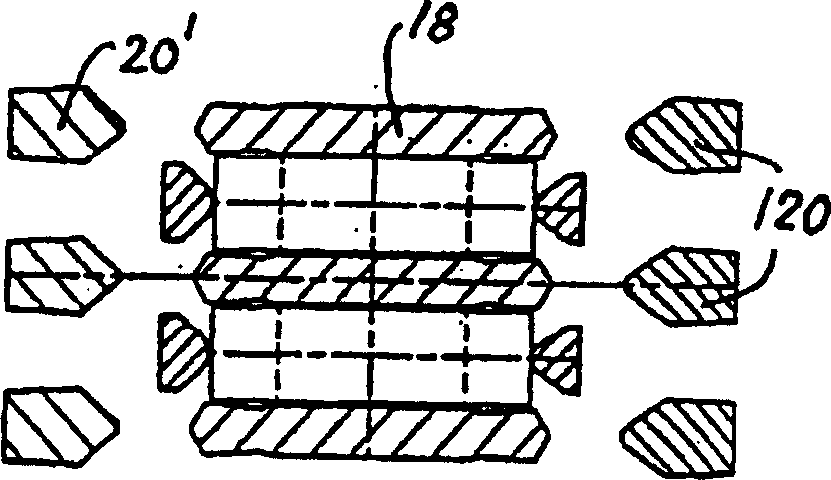

Structuring system for synchronising devices for a gearbox, whereby the synchronising device comprises: a carrier (6) which is mounted on, and for joint rotation with, a gearbox shaft (4) and which has not only a hub portion (8) connected to the shaft but also a web portion (10), which carrier supports for joint rotation with it but axial mobility relative to it a surrounding shift sleeve (16) whereby the carrier can be coupled to a coupling element (22',22'') fastened firmly to a gearwheel mounted rotatably on the shaft; at least one inner synchronising ring (28, 40) with conical outer friction surface; an outer synchronising ring (24a, 24b) with conical inner friction surface and external locking teeth (26); an intermediate synchronising ring (34) fitted between the inner and outer synchronising rings. The structuring system is usable for single, double or triple synchronisation versions, and the outer synchronising ring (24a, 24b) has driving protrusions (36a, 36b) which engage at least halfway in the web portion of the carrier. Each driving protrusion is situated in an engagement aperture (38). The synchronising ring (28, 34) immediately within the outer synchronising ring provided with locking teeth (26) has on its side facing away from the web portion of the carrier axial driving protrusions (30a, 30b) which each engage in respective adjacent coupling elements (22', 22'').

Owner:SCANIA CV AB

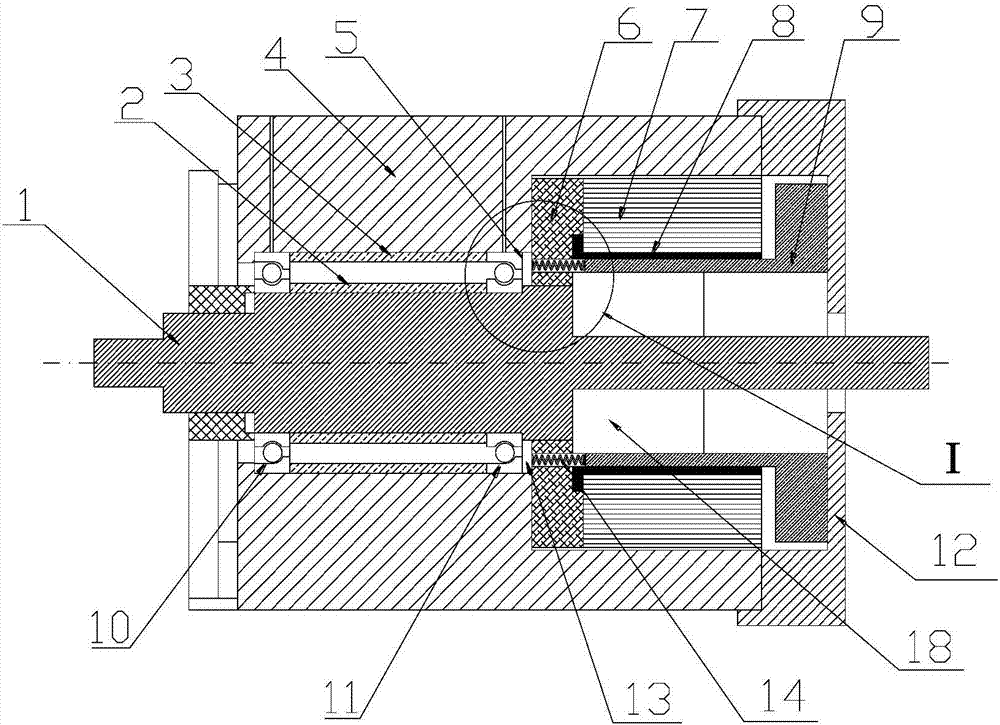

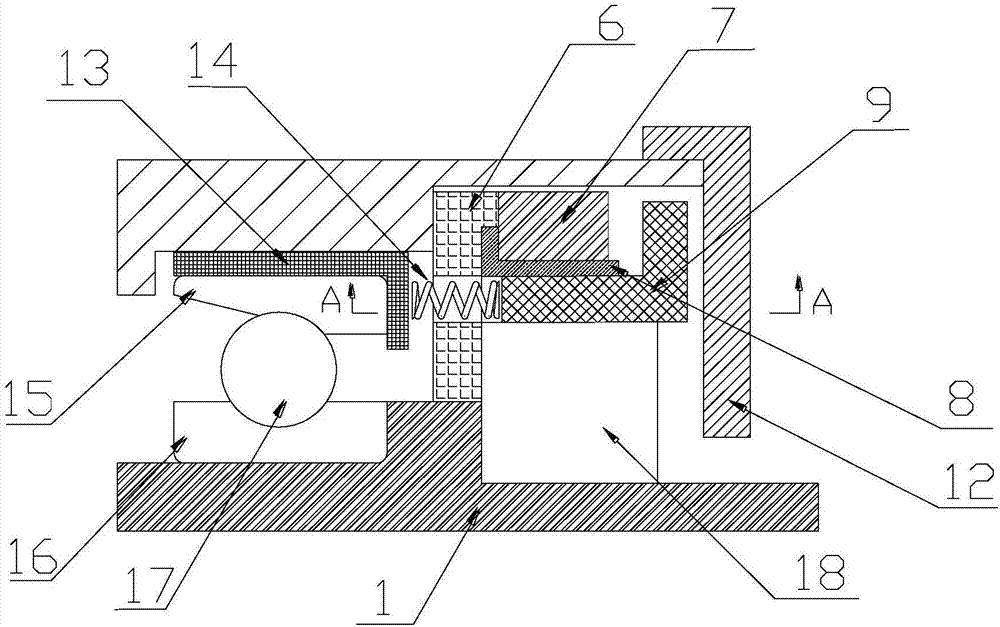

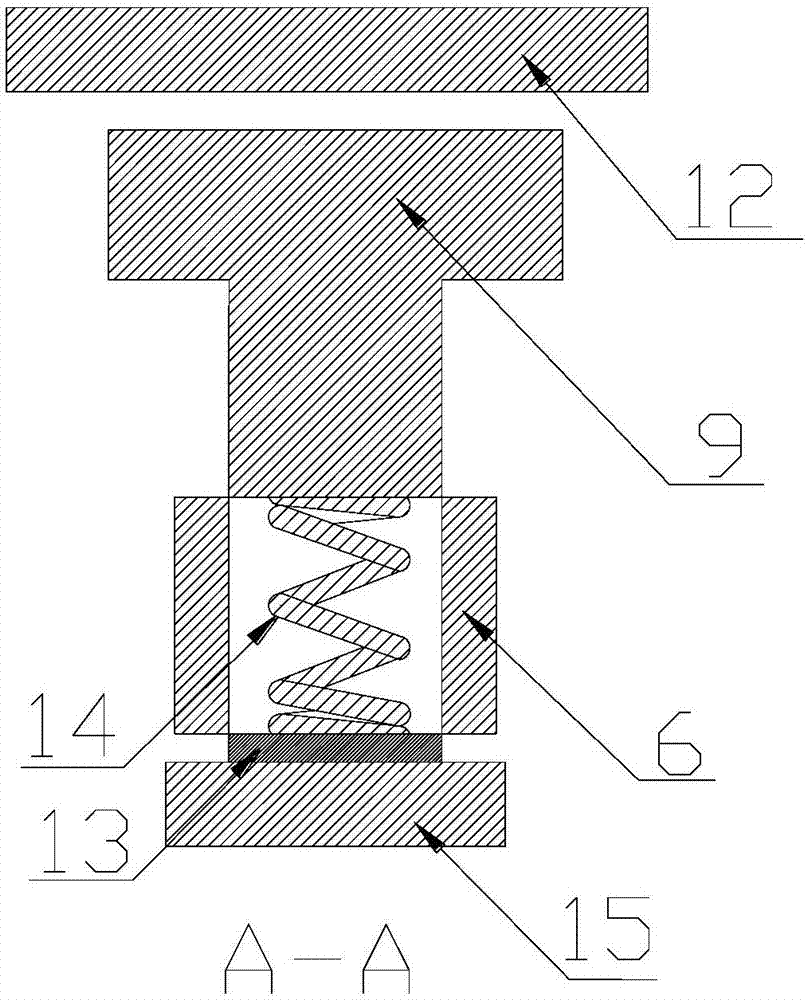

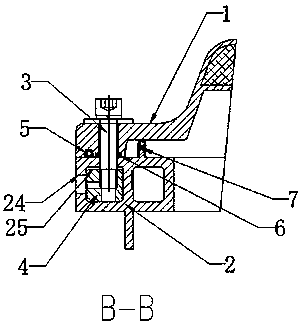

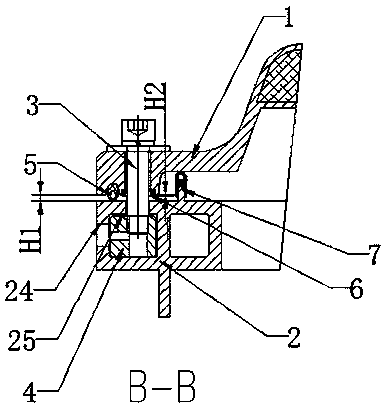

Dynamic adjusting device and method for pre-tensioning force of main shaft bearing of machine tool

PendingCN107262745ADynamically adjustable preloadIncrease preloadGeometric CADLarge fixed membersEngineeringMachine tool

The invention provides a dynamic adjusting device and method for pre-tensioning force of a main shaft bearing of a machine tool. The device comprises a force sensor, a fixed part, an electromagnet, an embedding sleeve, a moving part, an end cover, a spacer, a constant-pressure pre-tensioning spring and a supporting block, wherein the fixed part and the supporting block are connected with the main shaft; the electromagnet is fixedly connected with the embedding sleeve to form a combined body; the embedding sleeve sleeves a main shaft in an embedding manner and is connected with the fixed part; the spacer is mounted on an outer circle of a rear bearing; the moving part is inserted between the supporting block and the embedding sleeve, and two surfaces of the moving part are correspondingly in contact with the supporting block and the embedding sleeve; the constant-pressure pre-tensioning spring passes through a through hole of the fixed part; one end of the constant-pressure pre-tensioning spring is in contact with the spacer, and the other end of the constant-pressure pre-tensioning spring is in contact with the moving part; the end cover is connected with the housing; the force sensor is mounted on the outer circle of the rear bearing and is in contact with the spacer. According to the method, the electromagnetism can be changed by simply controlling the electrifying current of an electromagnet coil, and thus the pre-tensioning force of the bearing can be dynamically adjusted.

Owner:HEBEI UNIV OF TECH

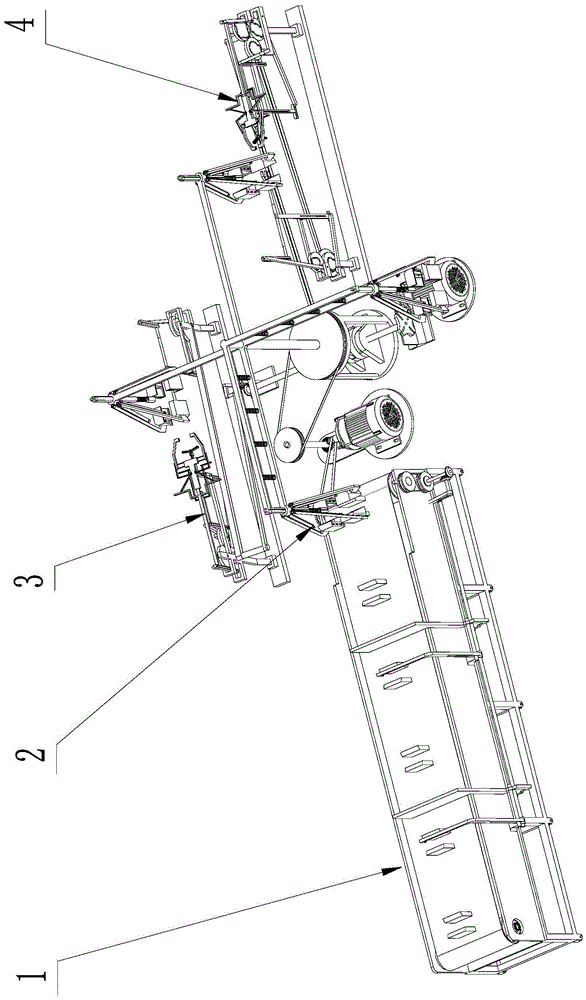

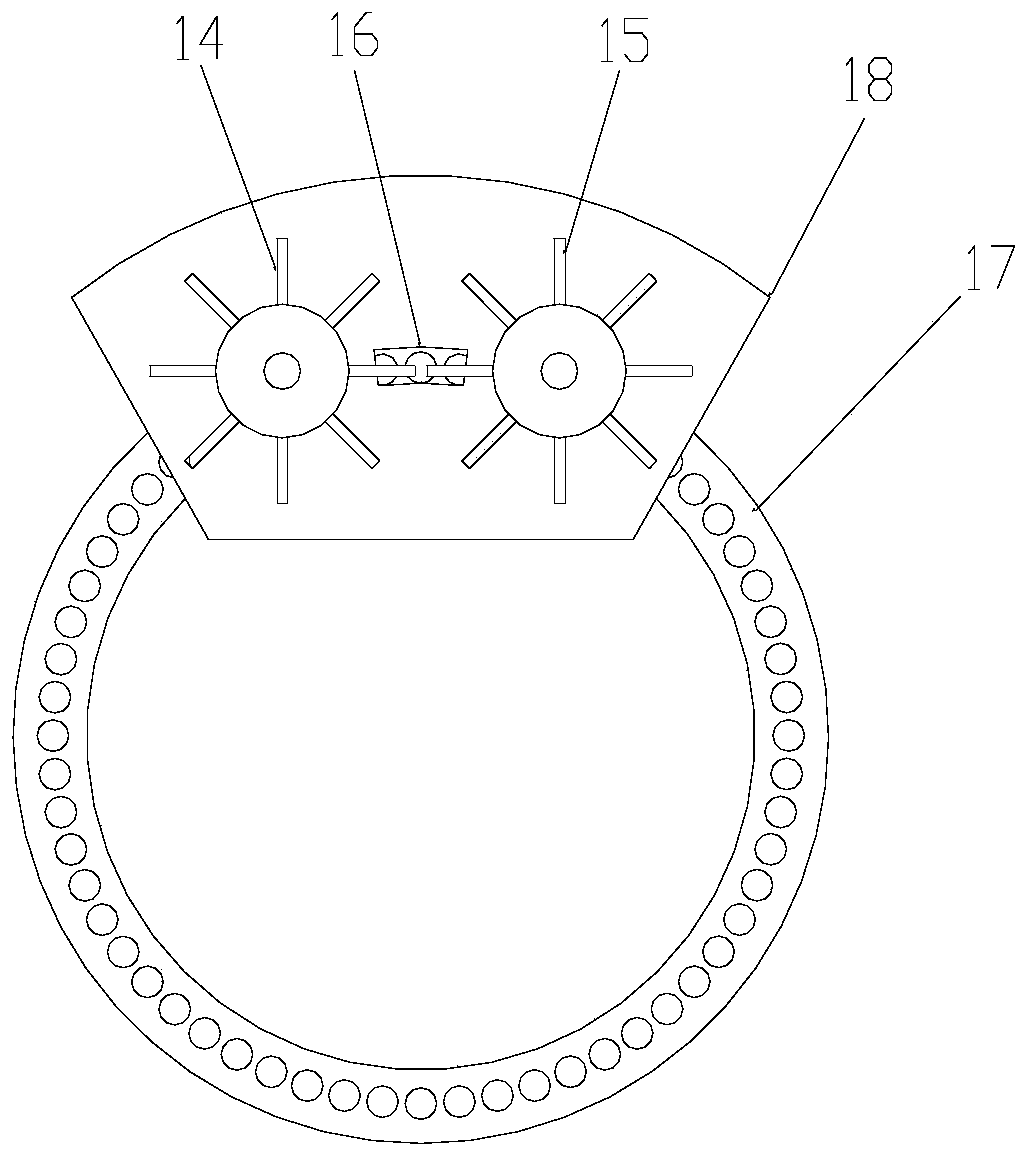

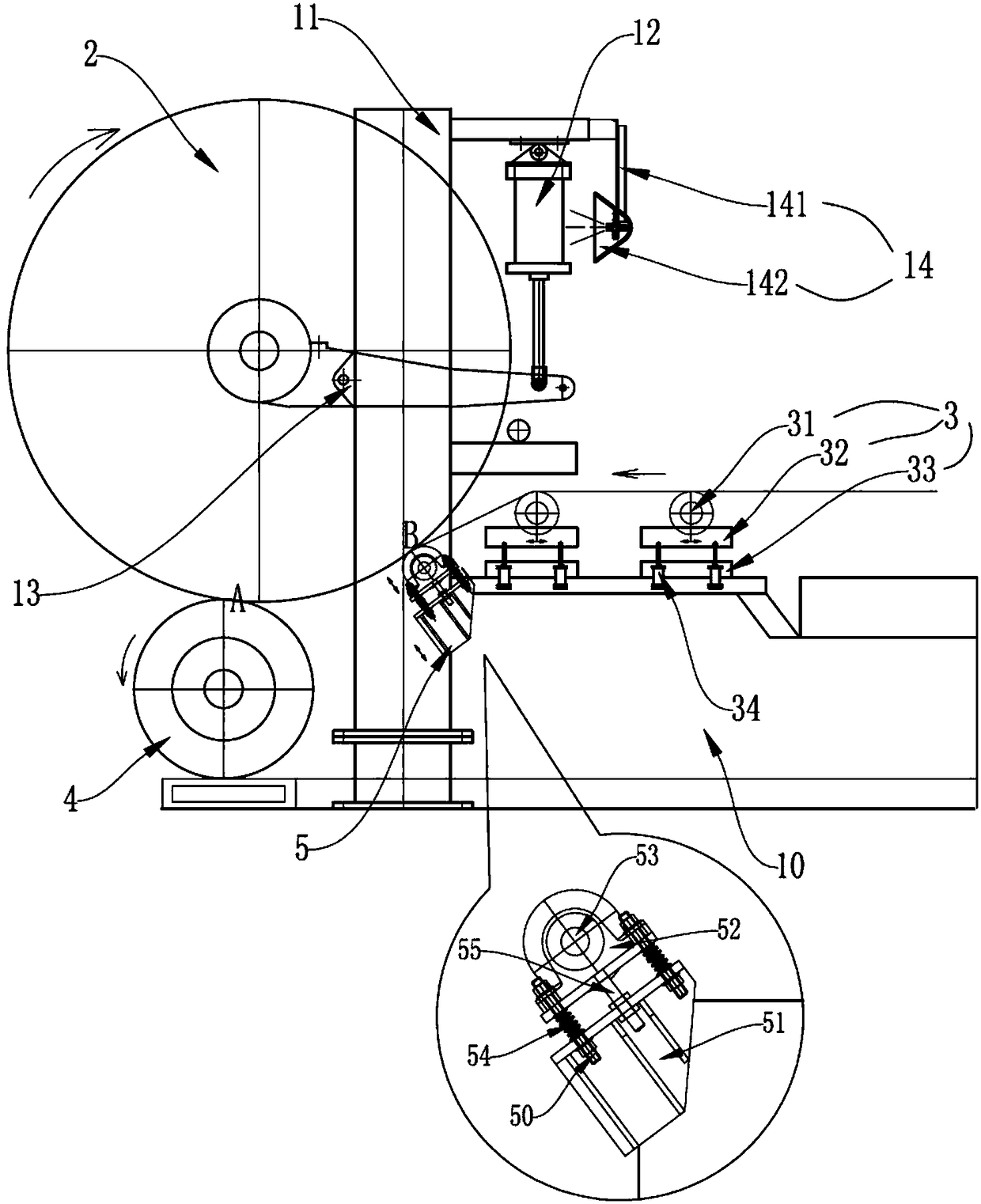

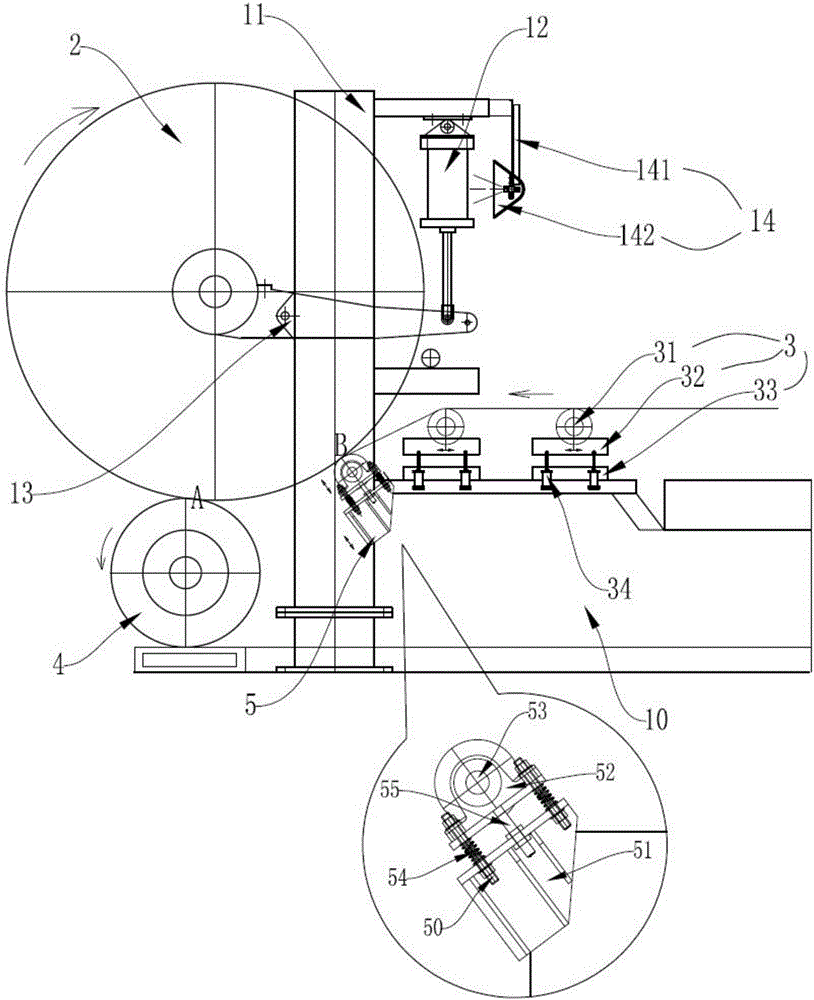

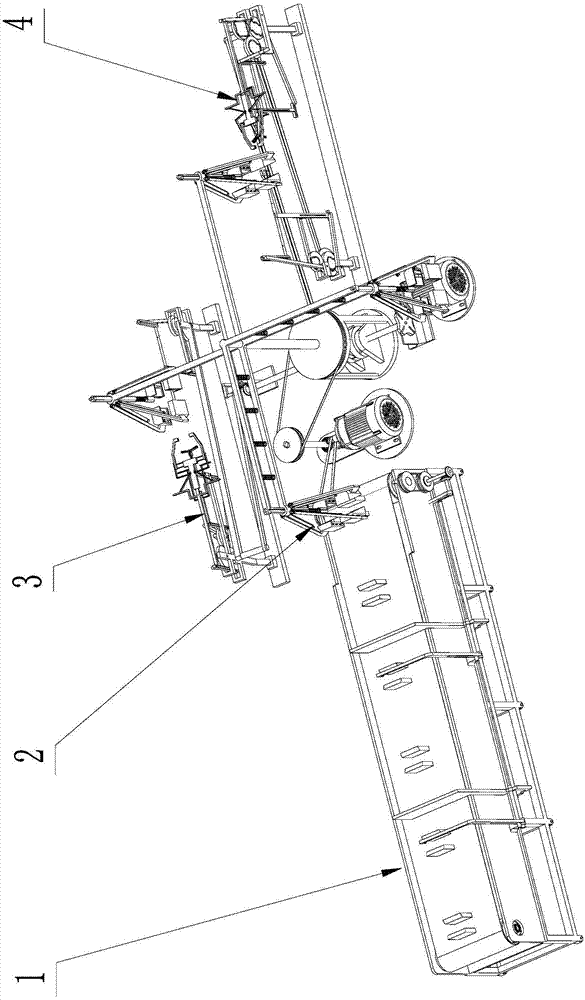

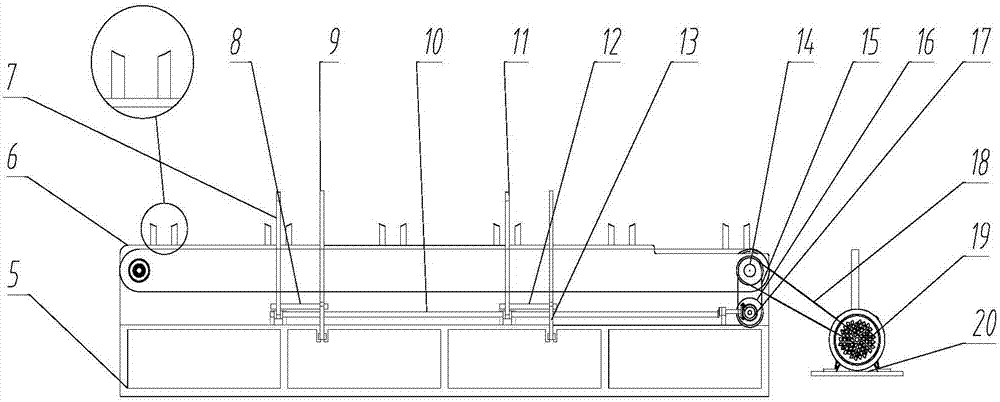

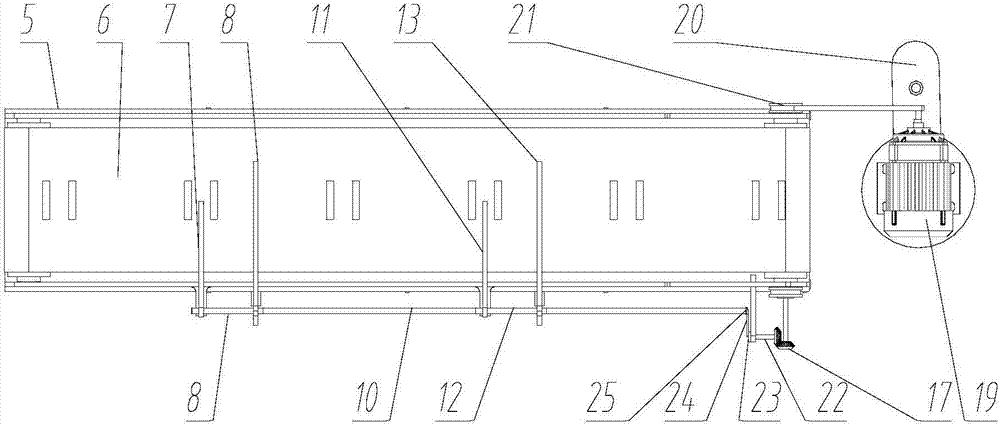

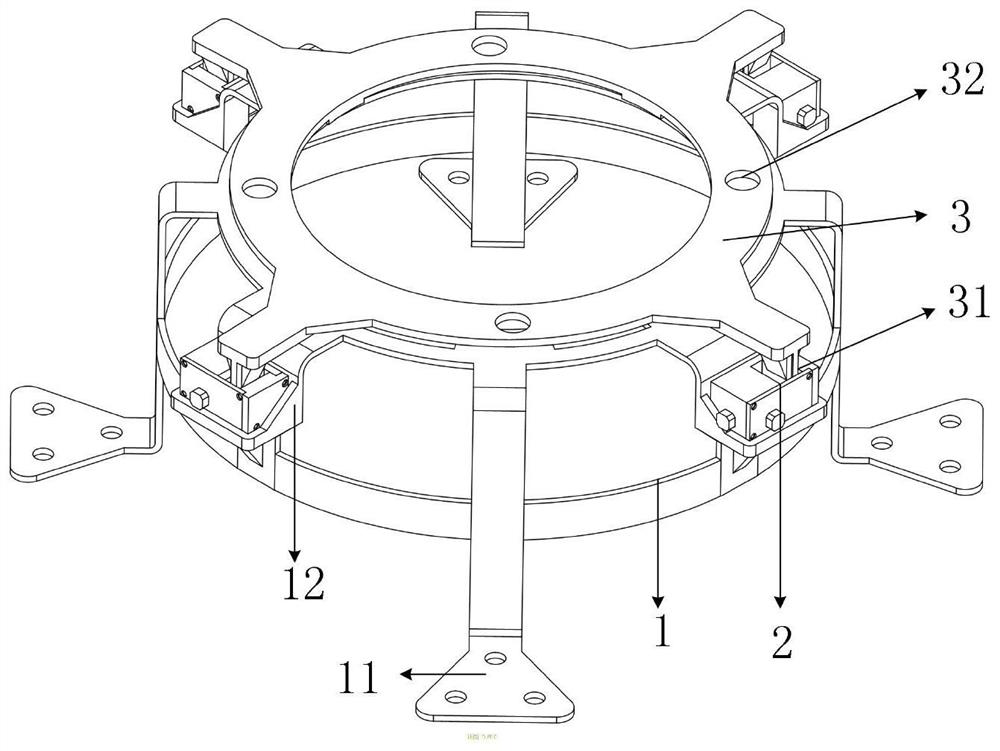

Multi-station flexible hairy crab shaping and binding integrated machine and using method thereof

ActiveCN105539912AReasonable allocation of assembly line workImprove productivityConveyorsBinding material applicationEngineeringSelf adaptive

The invention discloses a multi-station flexible hairy crab shaping and binding integrated machine and a using method thereof. The shaping and binding integrated machine adopts a four-station system to work, the joint of a conveying and righting device and a flexible hairy crab gripping device achieving self-adaptive fixation serves as the first station, the joint of a transverse rope binding device and the flexible hairy crab gripping device achieving self-adaptive fixation serves as the second station, the joint of a longitudinal rope binding device and the flexible hairy crab gripping device achieving self-adaptive fixation serves as the third station, and the position of the final case packing part serves as the fourth station. By means of line production of the four-station system, the manual labor cost is reduced; meanwhile, by means of adjustment of the operation time of all the stations, the optimal design of the system is achieved, and the working efficiency is further improved; the transverse rope binding device and the longitudinal rope binding device imitate the manual knotting sequence, a traditional manual one-rope cross-shaped rope binding mode is changed into the fixed binding mode that two ropes are used for transversely binding legs of a hairy crab to achieve firm binding, and then longitudinal rope binding is conducted once, and binding firmness is guaranteed.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

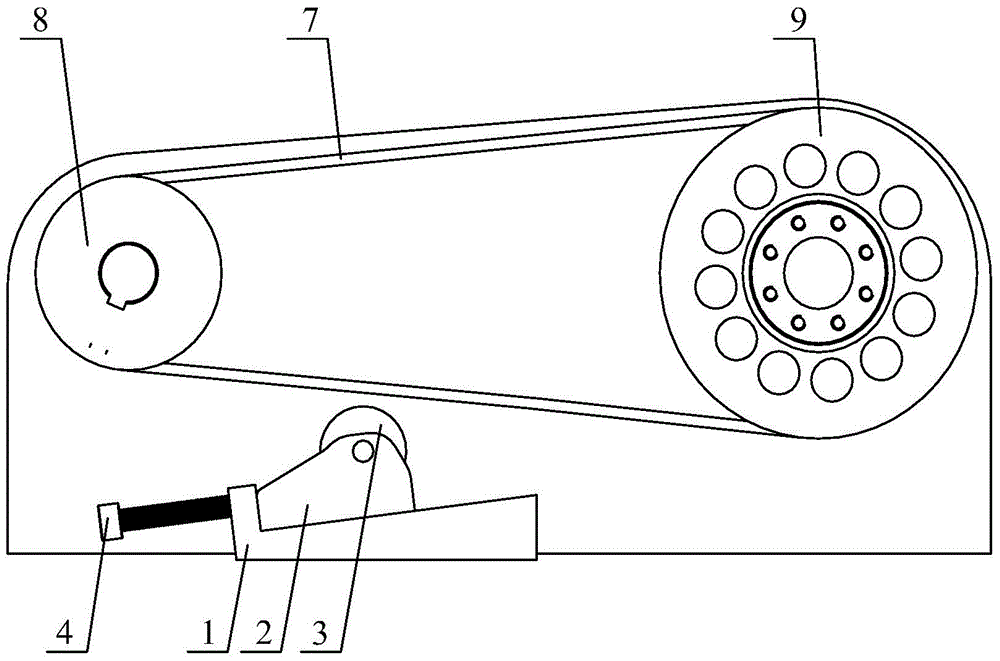

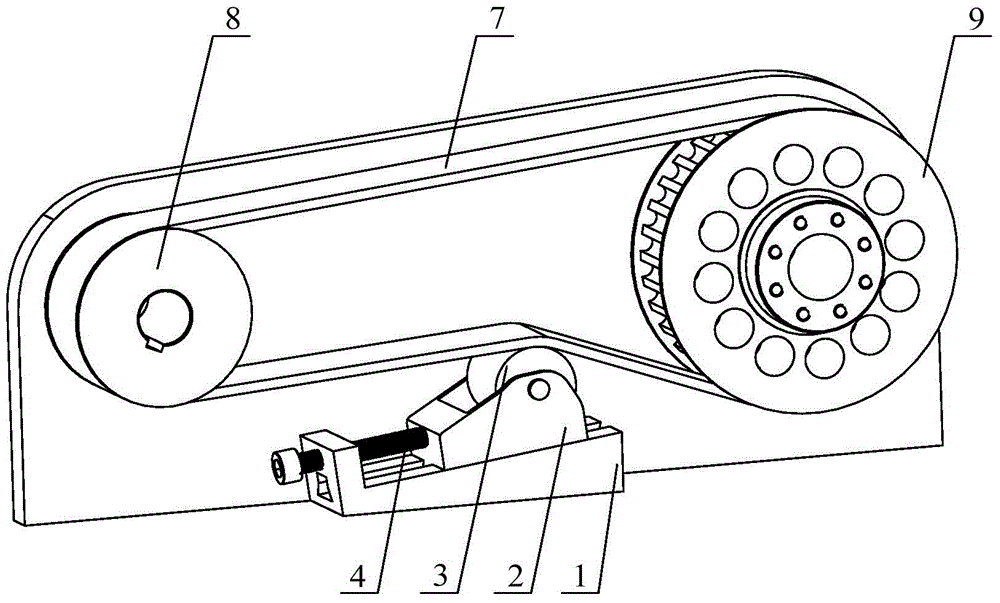

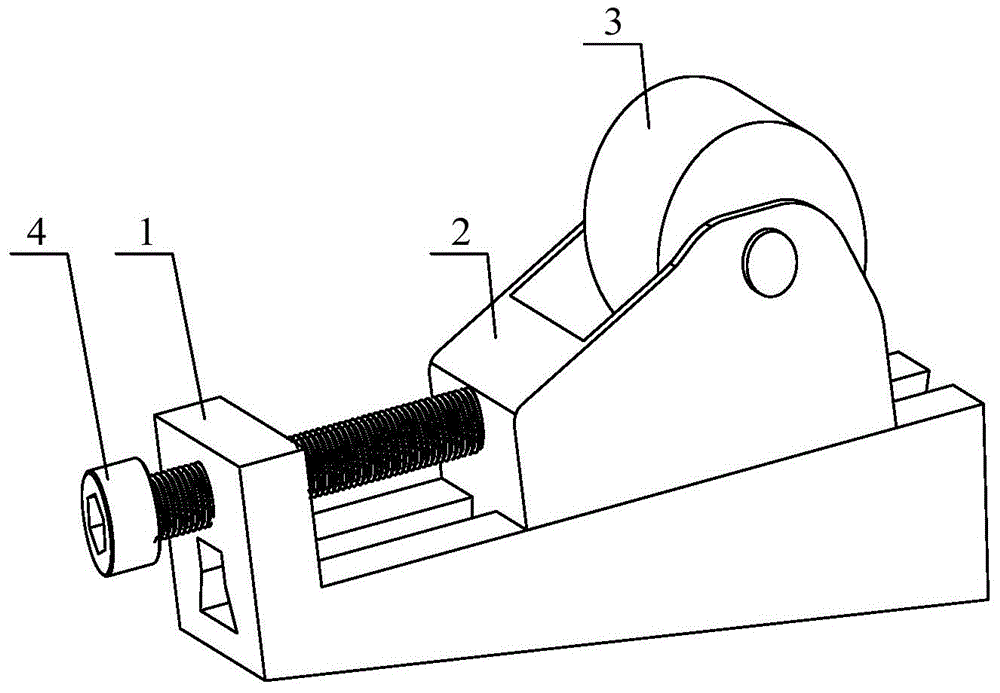

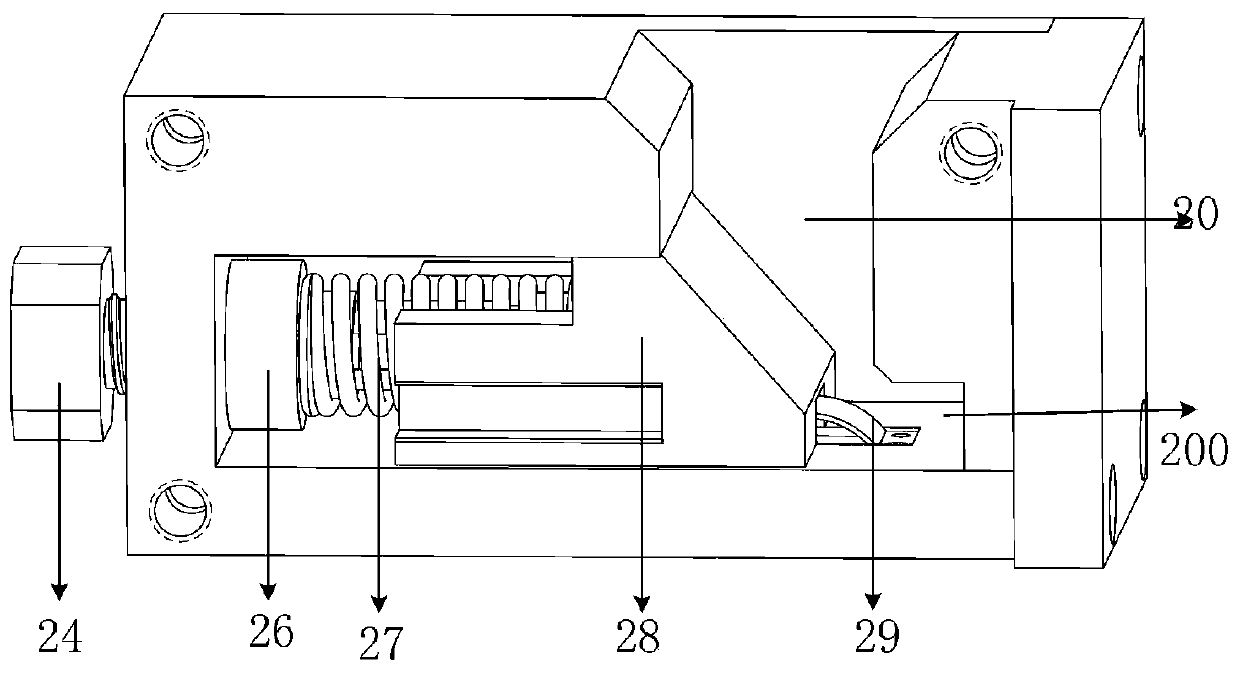

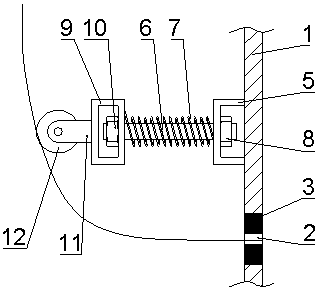

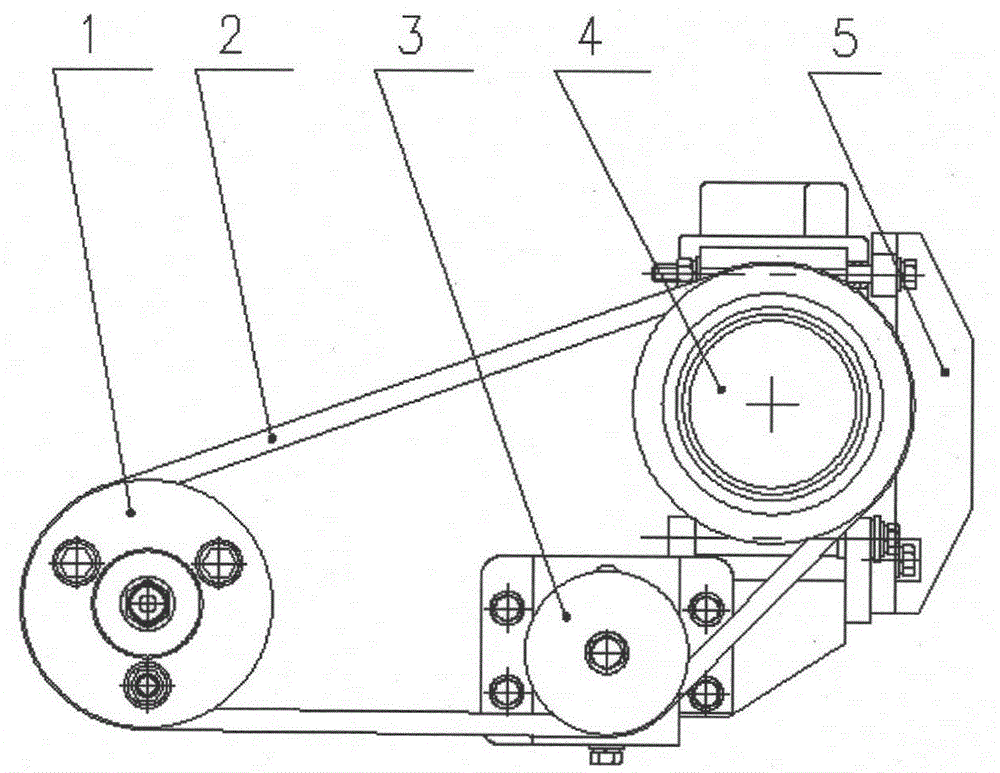

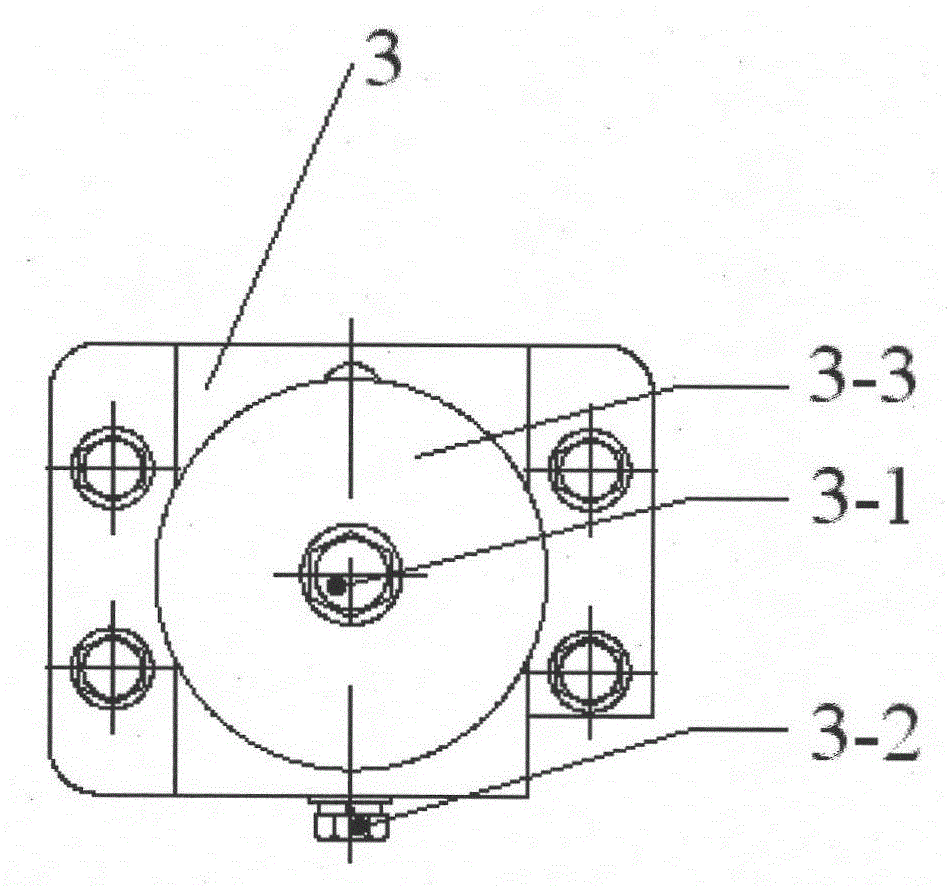

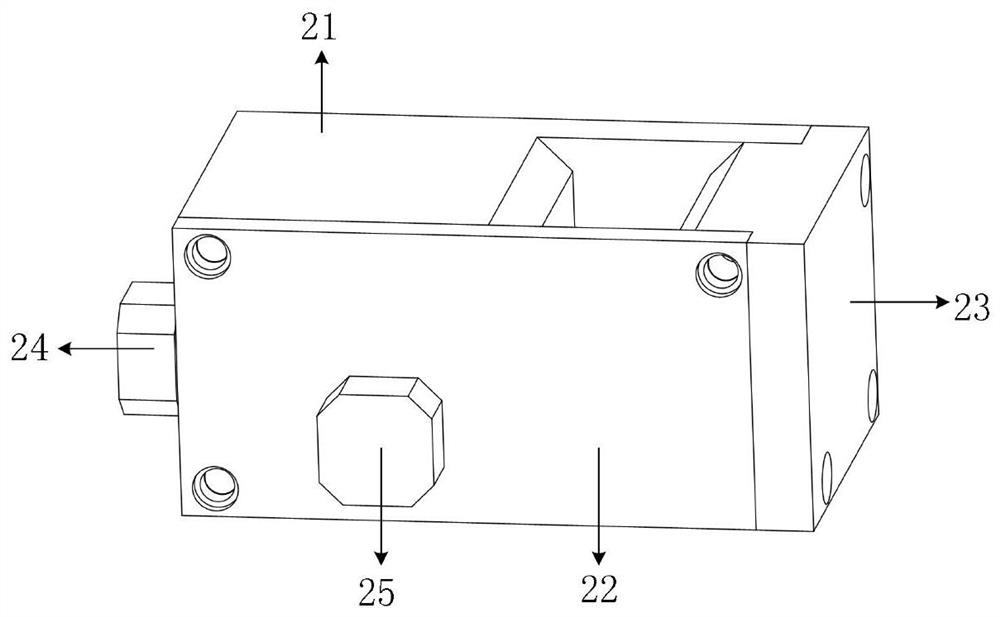

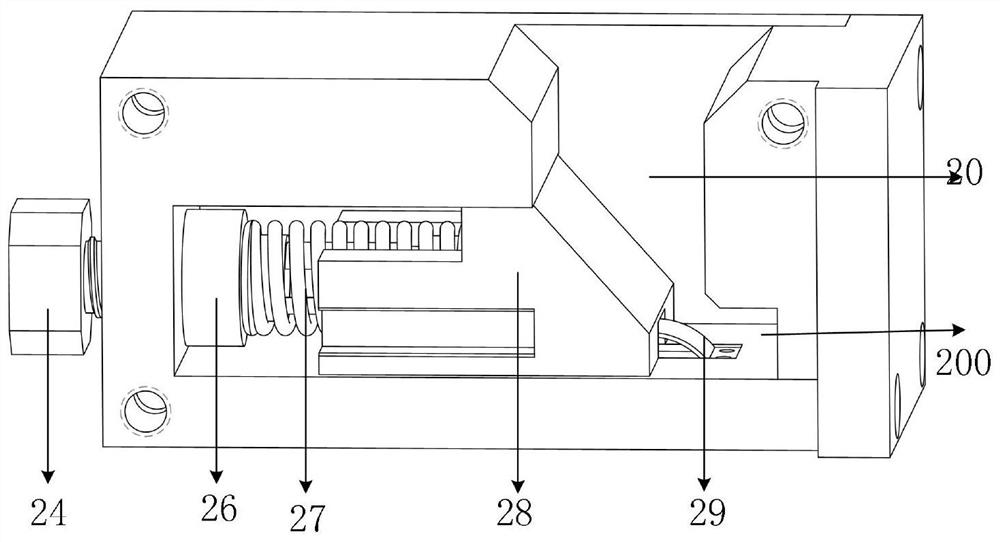

Transmission belt pre-tensioning device

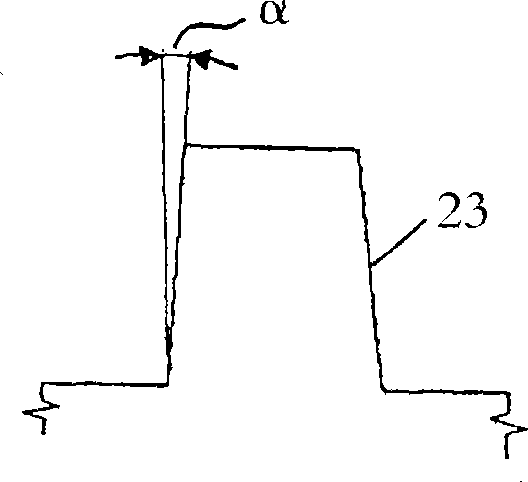

ActiveCN104401660AImprove preload accuracyAchieving minor adjustmentsConveyorsTransmission beltAcute angle

The invention discloses a transmission belt pre-tensioning device. The device comprises a tensioning wheel, a fixed part, a sliding block and a thread adjusting part; the thread adjusting part is in threaded connection to the fixed part and is used for driving the tensioning wheel to move in the direction close to or away from a transmission belt; a sliding groove is formed in one of the fixed part and the sliding block, and a guide rail contained in the sliding groove is arranged on the other of the fixed part and the sliding block; the direction of the axis of the thread adjusting part is the same as the extending direction of the sliding groove; and an acute angle is formed between the motion direction of the thread adjusting part and the motion direction of the tensioning wheel. On the basis of the principle that the bevel side of a triangle is longer than the right-angle side, when the thread adjusting part drives the sliding block to move, and further drives the tensioning wheel to move, the moving distance of the thread adjusting part is larger than the moving distance of the tensioning wheel in the unit time. With respect to the condition that in the prior art, the moving distance of a screw is the moving direction of the tensioning wheel, the transmission belt pre-tensioning device achieves tiny adjustment of the tensioning wheel, and the pre-tensioning precision of the transmission belt is improved.

Owner:CHANGZHOU QIANJING REHABILITATION CO LTD

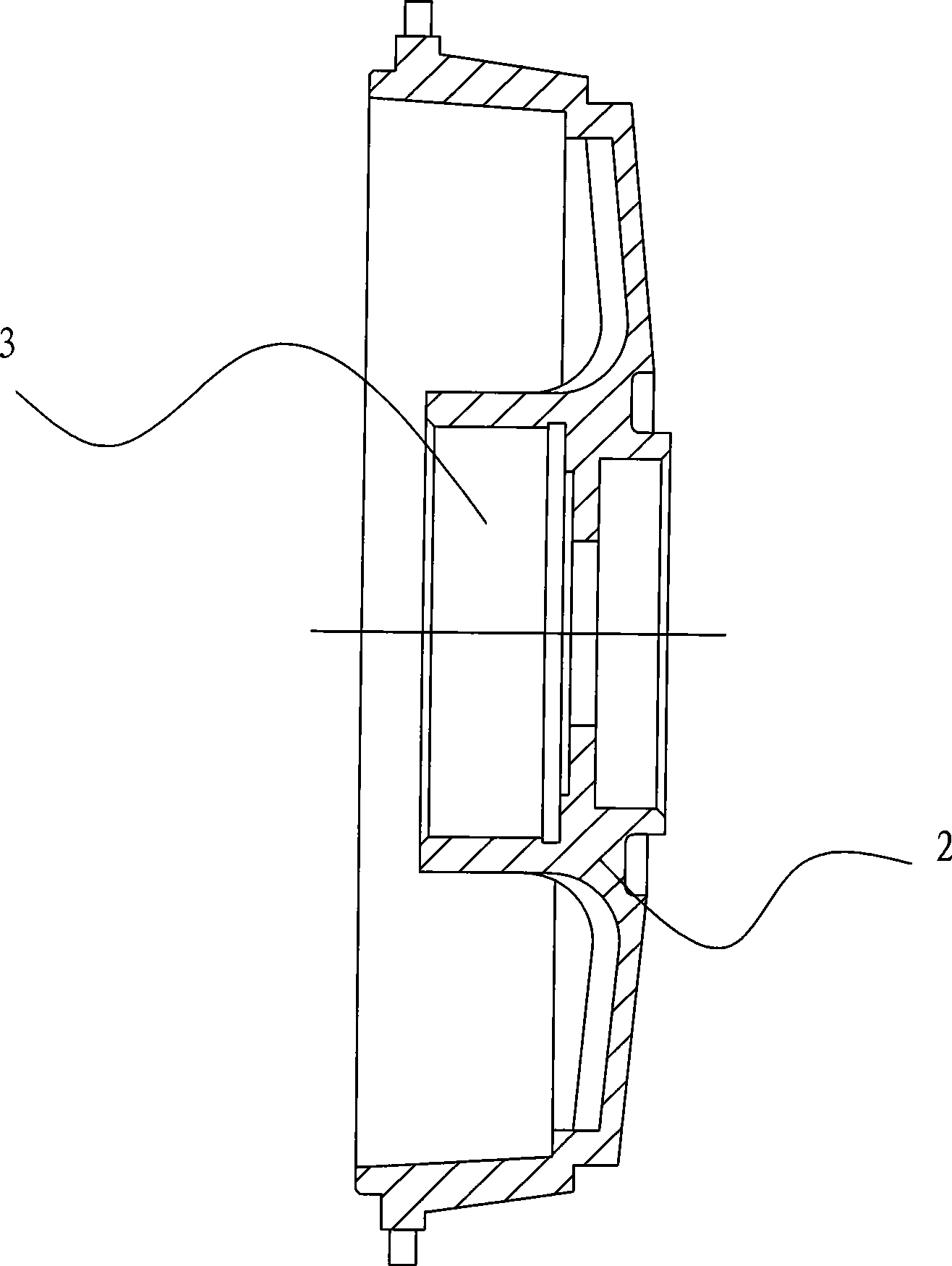

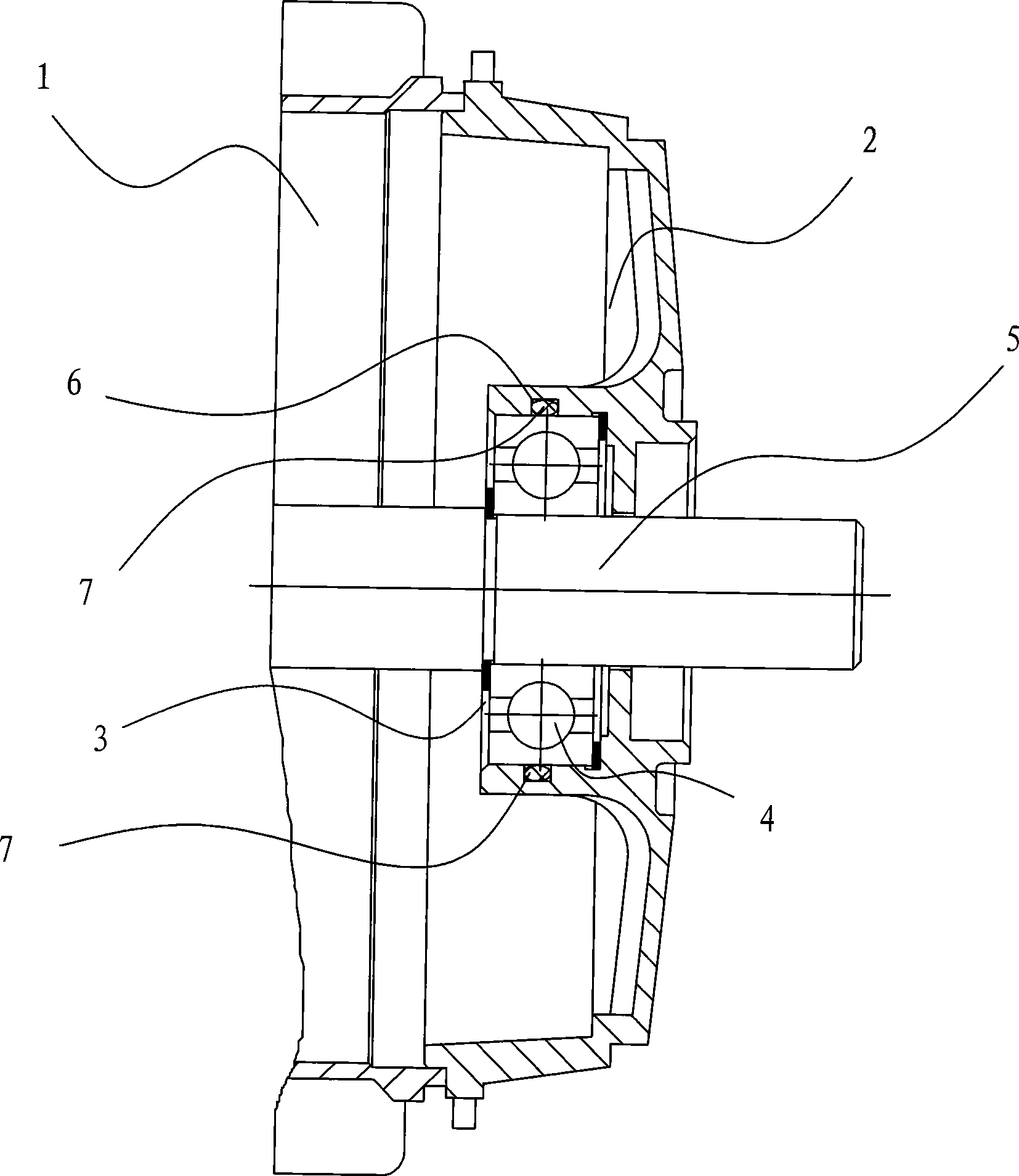

Macro and micro-driving type linear piezoelectric motor and driving method thereof

ActiveCN103281005ASimple processing technologyCompact structurePiezoelectric/electrostriction/magnetostriction machinesStanding waveUltrasonic motor

The invention discloses a macro and micro-driving type linear piezoelectric motor and a driving method thereof, and relates to the field of the ultrasonic motor and micro driving. The motor comprises a rack, a driving vibrator, an active cell and a pre-tightening mechanism, wherein the driving vibrator comprises a metallic elastomer, a micrometric displacement amplification elastomer and a piezoelectric element; the two symmetrical convex teeth on the inner side of the micrometric displacement amplification elastomer are in frictional contact with the active cell; and the piezoelectric element is polarized along the thickness direction. The motor macro driving method is characterized in that two longitudinal standing waves of which the phase difference is 90 degrees, the frequencies are closed, and the type are the same are stimulated by the vibrator under the action of the alternating current of which the phase difference is 90 degrees; after the standing waves are combined, an elliptic movement locus is formed on the convex tooth part; and under the pre-tightening force action, the active cell generates the macro linear movement. According to the micro-driving method, direct-current high voltage is applied to the piezoelectric element, the vibrator generates static deformation, and the two symmetrical convex teeth on the inner side of the micrometric displacement amplification elastomer clamp the active cell and the micro linear movement is generated. According to the invention, the macro driving and the micro driving are simultaneously realized on one motor, and the invention has the characteristics of simple structure and reliability in working.

Owner:SOUTH CHINA AGRI UNIV

Motor with improved rear cap bearing support construction

The invention discloses an electric motor with a bearing seat structure of an improved rear end cover, which comprises a shell, a rear end cover is installed on the shell, a bearing chamber is arranged on the rear end cover, a bearing is installed in the bearing chamber and is connected with a rotating axle, a radial O-shaped ring pit slot is arranged on the inner wall of the bearing chamber, an O-shaped ring is arranged in the pit slot, and the outer wall of the bearing is closely matched with the O-shaped ring. Since the rubber O-shaped ring device is arranged in the bearing chamber of the rear end cover, therefore, the sealing performance is good; a pit slot is arranged on a bearing chamber 3; the processing technology is simple, and the cost is low.

Owner:开平市三威微电机有限公司

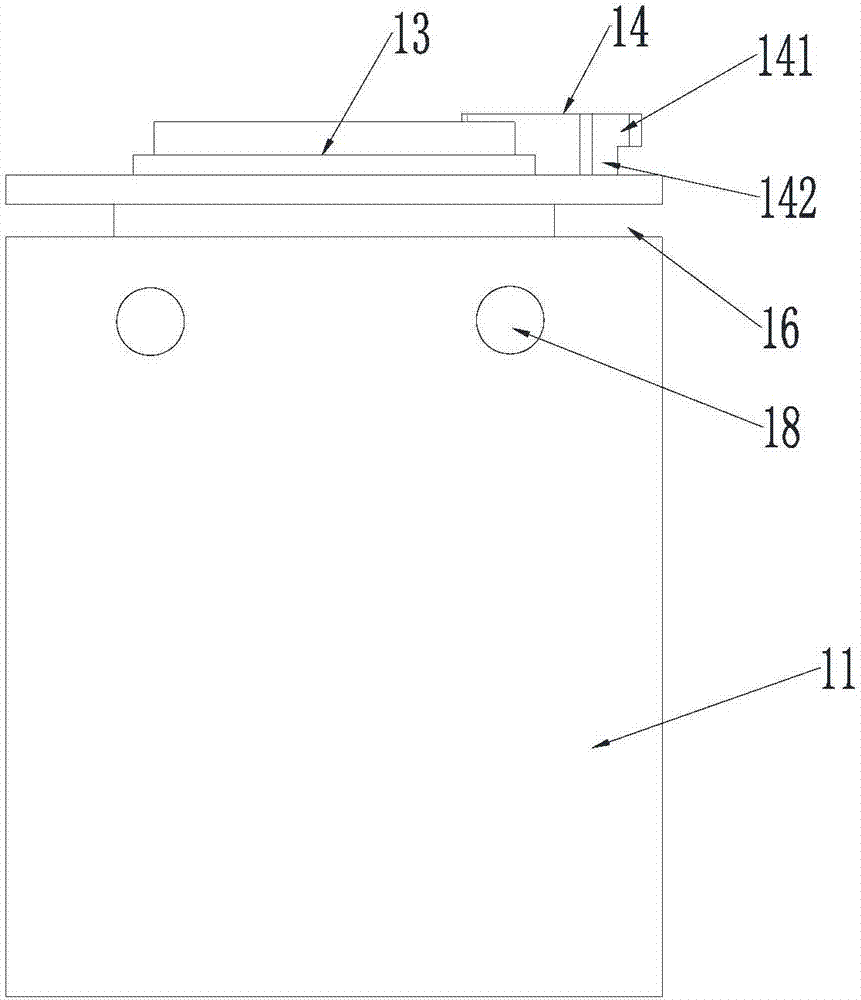

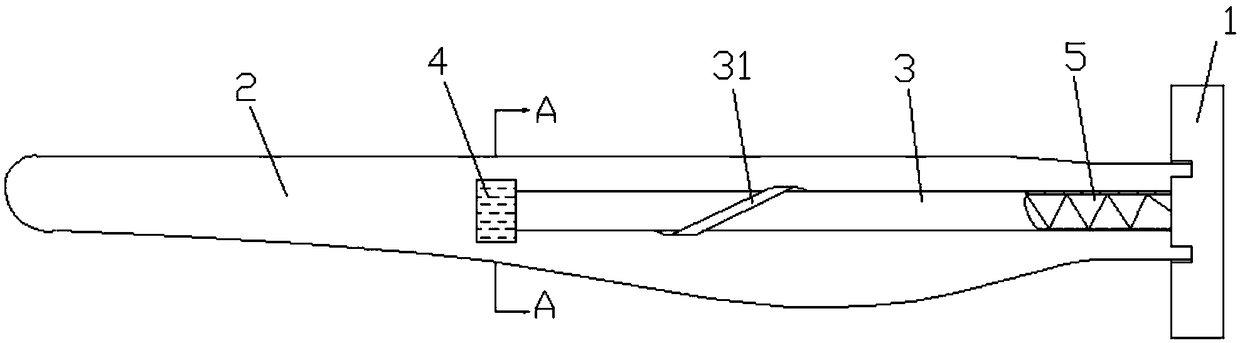

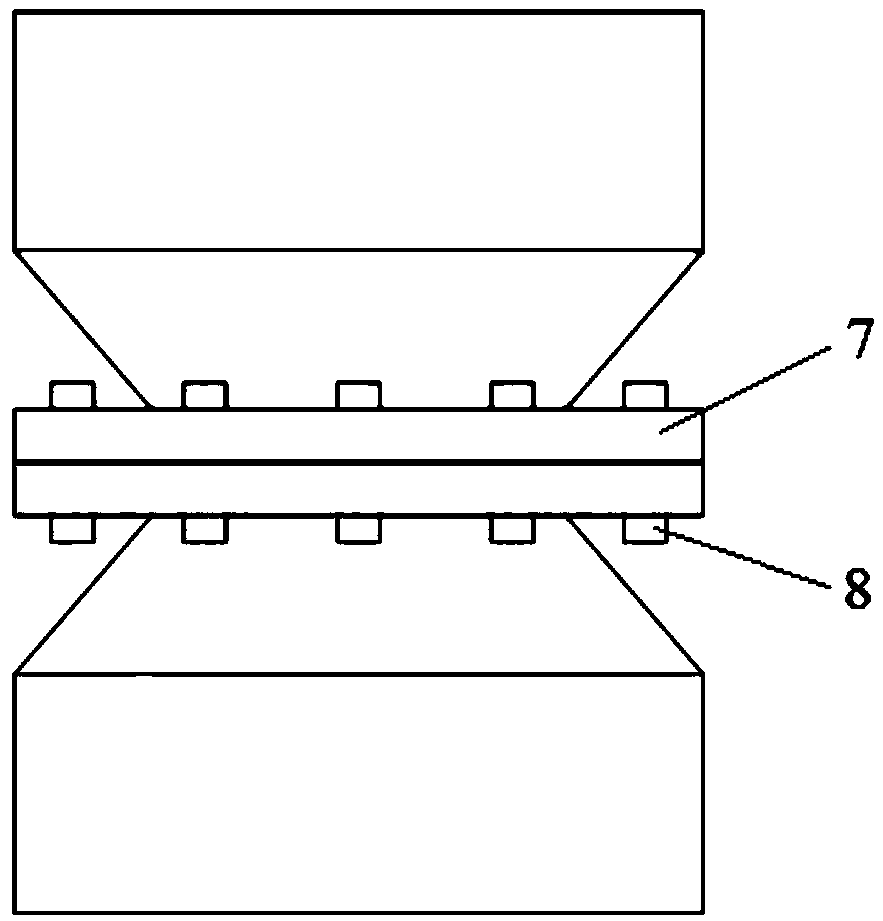

Tool for determining pre-tightening force of soft package battery, method for determining pre-tightening force of soft package battery and method for assembling soft package module

ActiveCN111537126ASolve the problem that the preload of the pouch battery cannot be determinedAppropriate preloadAssembling battery machinesFinal product manufacturePhysicsMechanical engineering

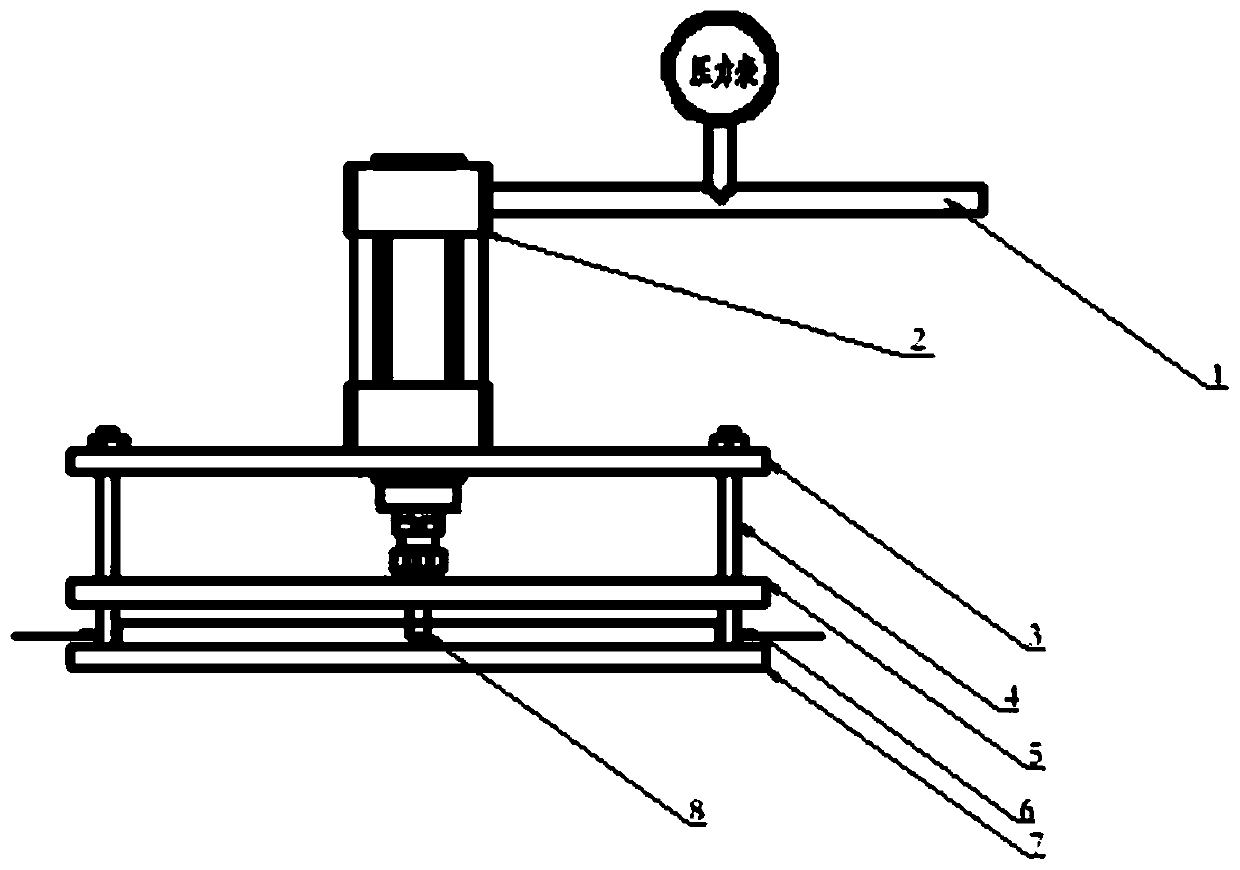

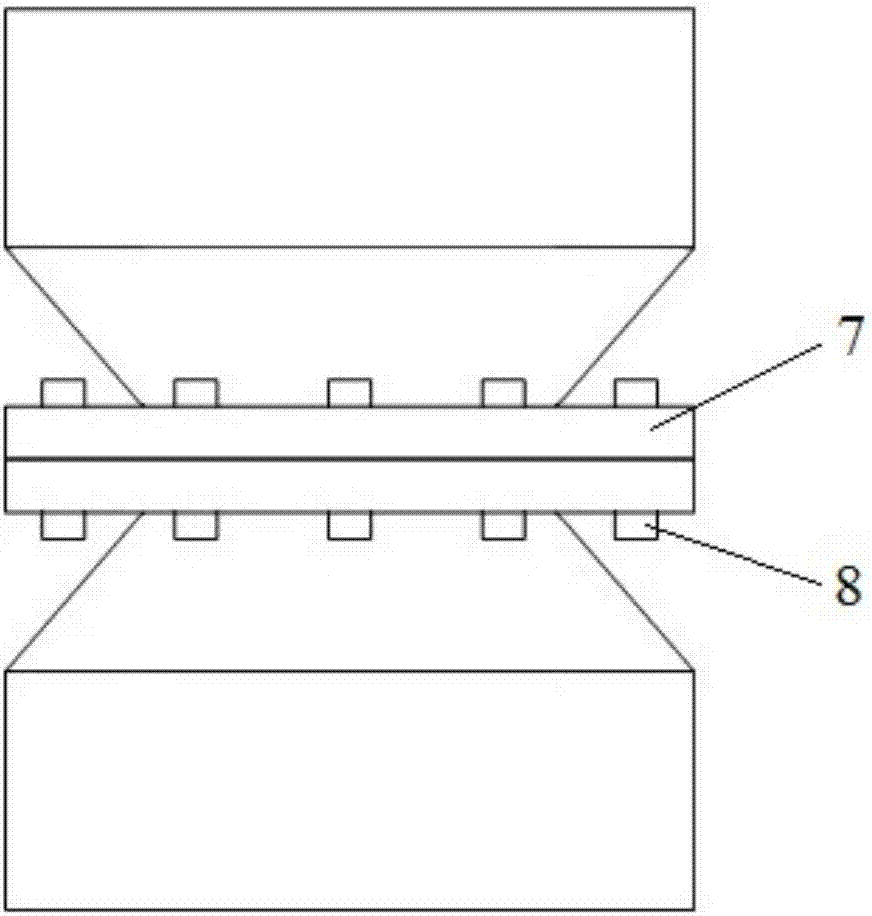

The invention discloses a tool for determining the pre-tightening force of a soft package battery, a method for determining the pre-tightening force of a soft package battery and a method for assembling a soft package module. The tool comprises an upper clamping plate and a lower clamping plate which are used for clamping a soft package battery, an air cylinder being arranged on an air cylinder fixing plate and used for applying a pressure to the upper clamping plate so as to clamp the soft package battery, a pressure monitoring device being connected with the air cylinder and used for monitoring the pressure between the soft package battery and the upper clamping plate, and a control device being connected with the pressure monitoring device and the air cylinder and used for adjusting thepressure applied to the upper clamping plate by the air cylinder according to pressure information fed back by the monitoring device. According to the tool, the pressure is applied to the upper clamping plate through the air cylinder, the air cylinder can be adjusted according to the pressure information, fed back by the pressure monitoring device, between the soft package battery and the upper clamping plate, so that the pressure between the soft package battery and the upper clamping plate is kept unchanged, and thus a problem that the pre-tightening force of the soft package battery cannotbe determined in the prior art is solved.

Owner:SUZHOU QINGTAO NEW ENERGY TECH CO LTD

Long metal filter bag butt joint structure, auxiliary installation tool and installation method thereof

InactiveCN107009321ASimple structureEasy to operateDispersed particle filtrationMetal-working hand toolsButt jointEngineering

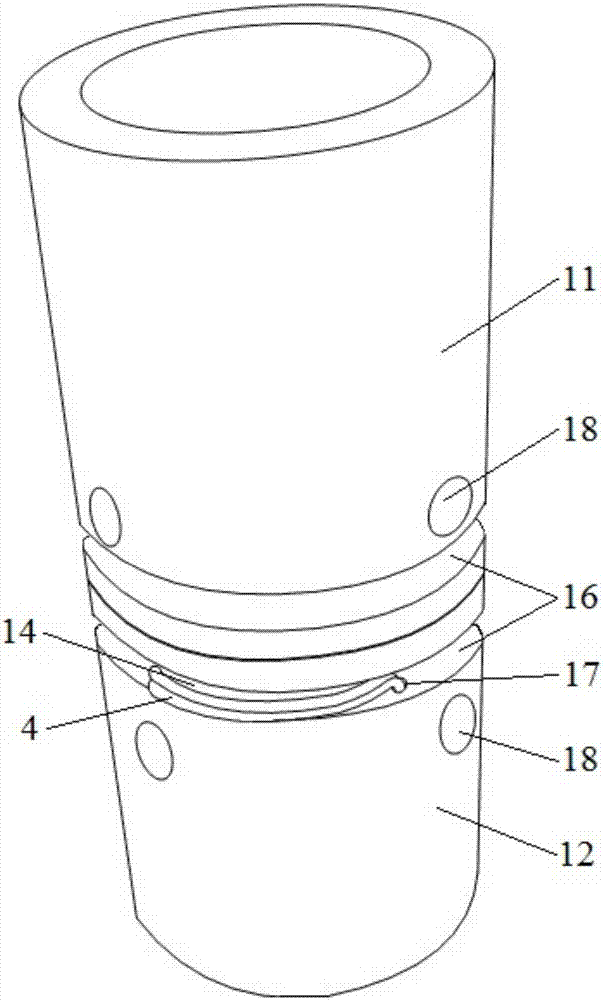

The invention relates to a long metal filter bag butt joint structure, an auxiliary installation tool and an installation method thereof. The long metal filter bag butt joint structure comprises a butt joint clamp pipe port and a butt joint sleeve pipe port in butt joint and respectively arranged in metal filter bag ports; an annular convex part in butt joint with an inner cavity of the butt joint sleeve pipe port is arranged on the end surface of the butt joint clamp pipe port; arc convex parts and arc concave parts are respectively arranged at the peripheries of the end surface edges of the butt joint clamp pipe port and the butt joint sleeve pipe port; annular grooves are respectively formed in the peripheries of the outer walls of the butt joint clamp pipe port and the butt joint sleeve pipe port; the arc concave parts communicate with the annular grooves; the arc concave parts include first arc grooves and second arc grooves for communicating with each other; the first arc grooves and the arc concave parts are distributed in an axial symmetry manner; the second arc grooves and the arc concave parts are distributed in a central symmetry manner; and the arc convex parts include first arc projections and second arc projections arranged up and down. Compared with the prior art, the long metal filter bag butt joint structure is excellent in tightness, simple and fast in disassembly and high in working efficiency.

Owner:XIAMEN UNIV TAN KAH KEE COLLEGE

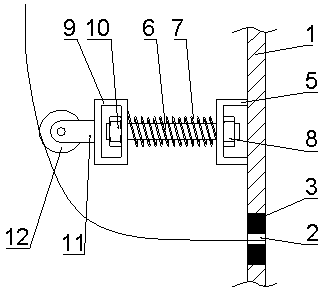

Connection device for mounting and dismounting wheel hub cover

ActiveCN110667303AReduce volumeCompact structureWheel protectionStructural engineeringMechanical engineering

Owner:YANSHAN UNIV

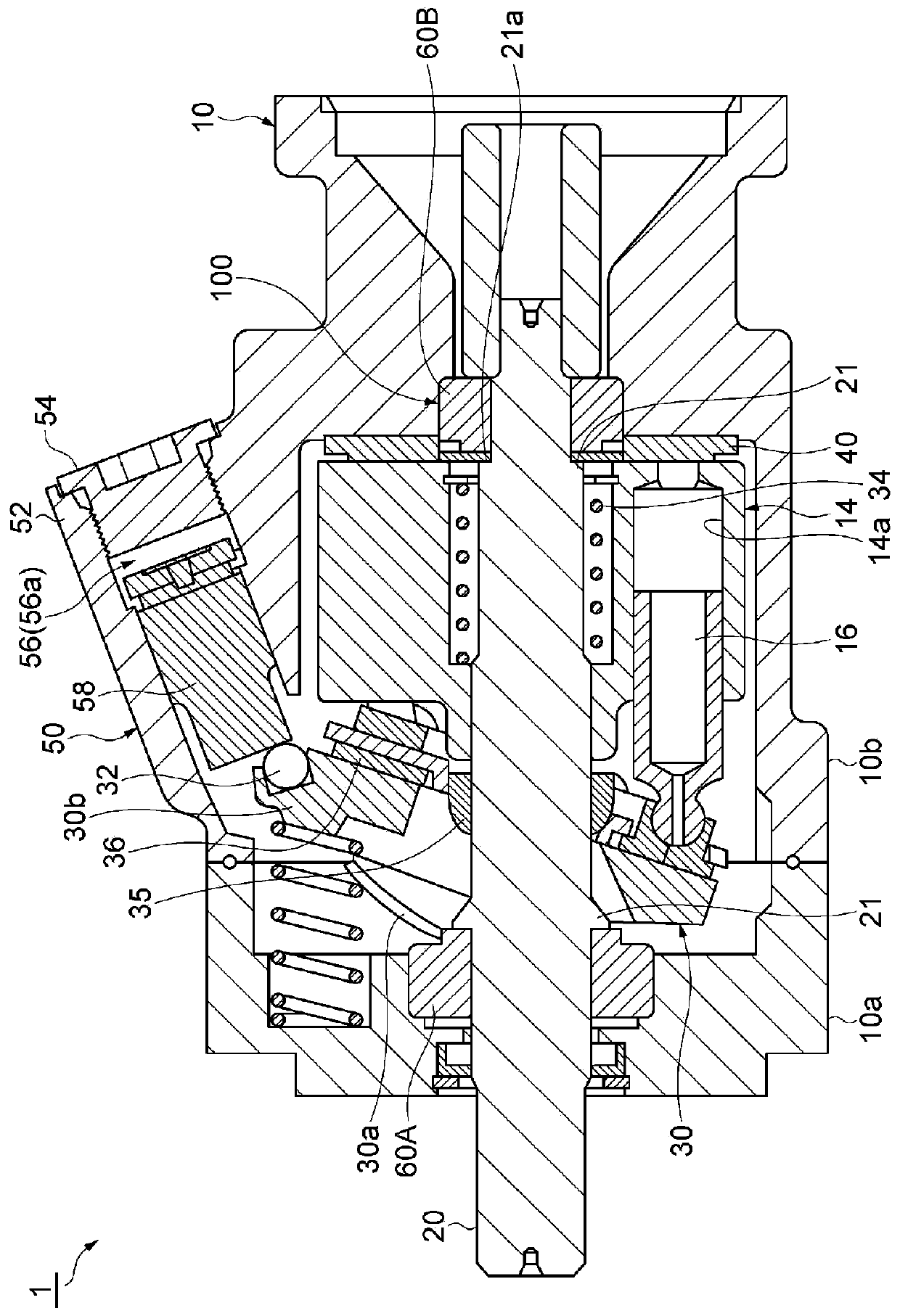

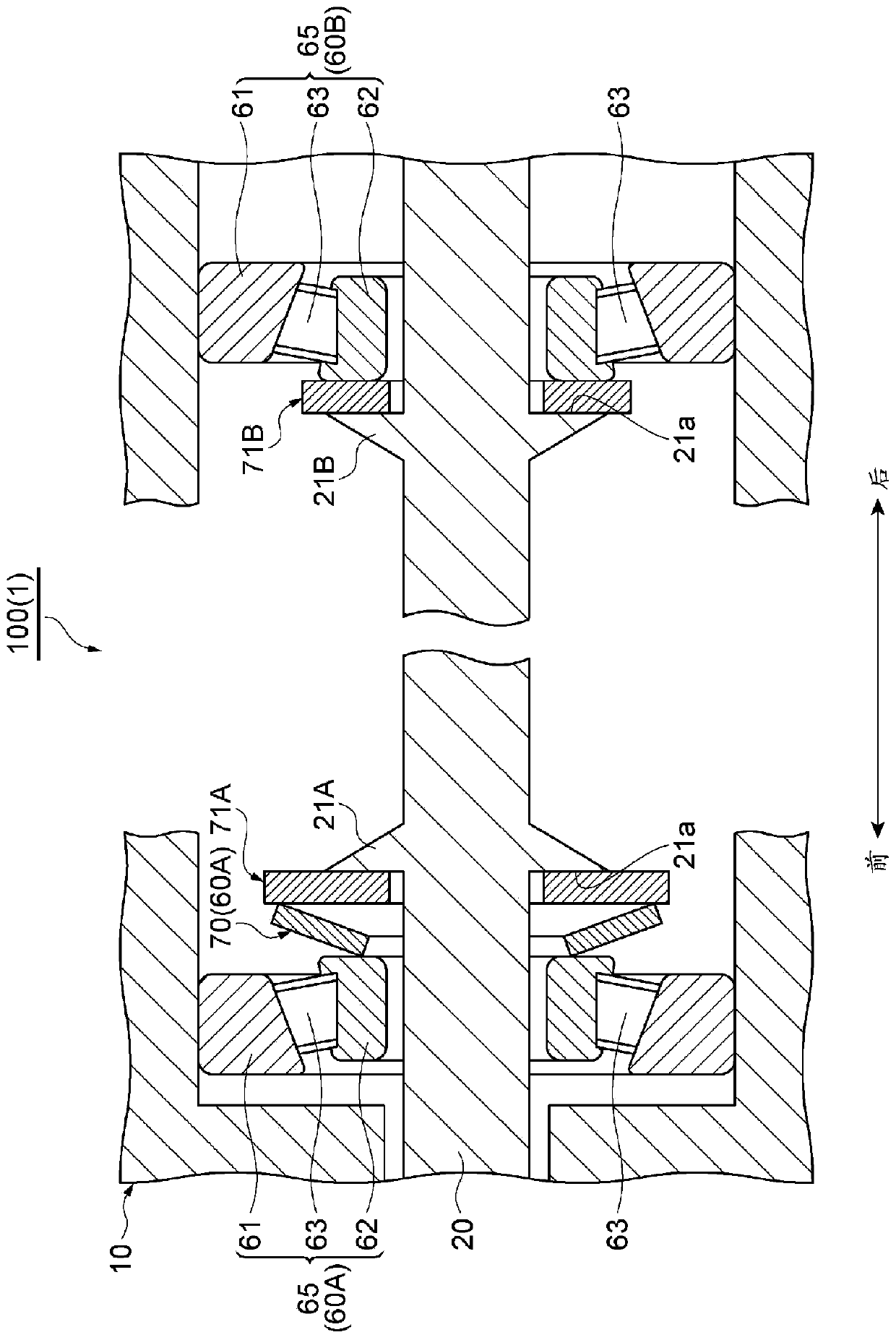

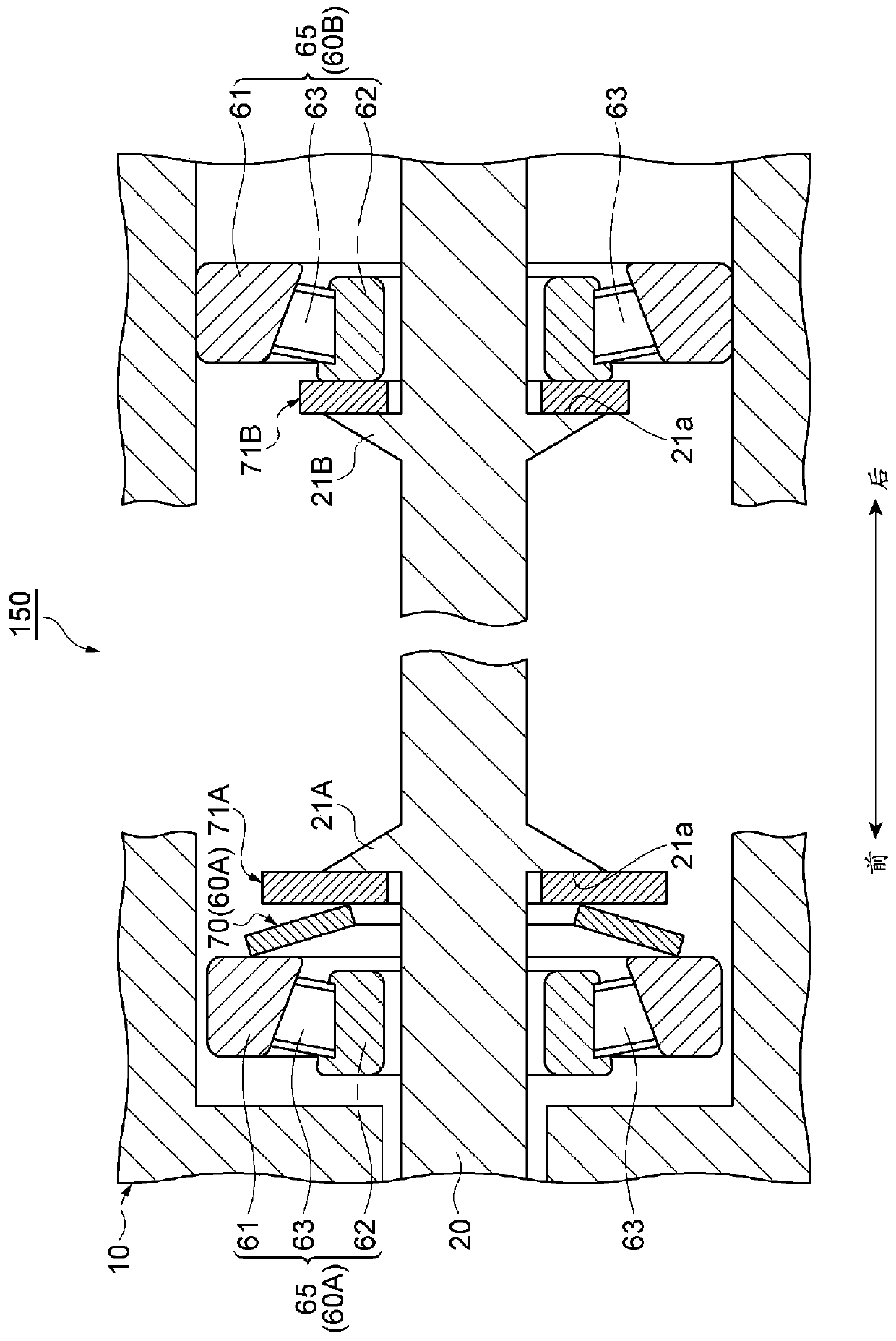

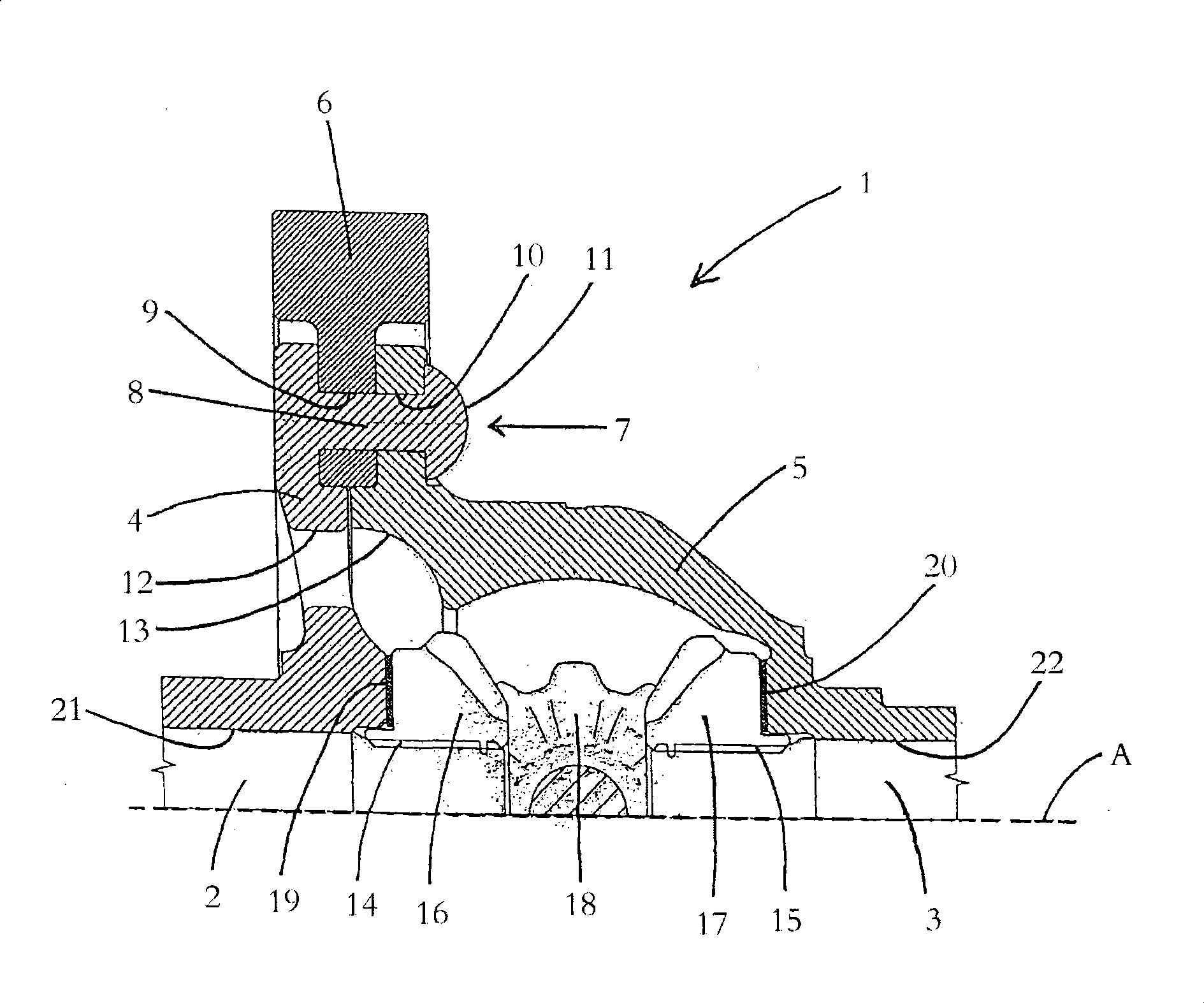

Assembly system for synchronizing devices in a gearbox

InactiveCN1281875CAppropriate preloadMechanical actuated clutchesCouplings for rigid shaftsGear wheelCoupling

Structuring system for synchronising devices for a gearbox, whereby the synchronising device comprises: a carrier (6) which is mounted on, and for joint rotation with, a gearbox shaft (4) and which has not only a hub portion (8) connected to the shaft but also a web portion (10), which carrier supports for joint rotation with it but axial mobility relative to it a surrounding shift sleeve (16) whereby the carrier can be coupled to a coupling element (22',22") fastened firmly to a gearwheel mounted rotatably on the shaft; at least one inner synchronising ring (28, 40) with conical outer friction surface; an outer synchronising ring (24a, 24b) with conical inner friction surface and external locking teeth (26); an intermediate synchronising ring (34) fitted between the inner and outer synchronising rings. The structuring system is usable for single, double or triple synchronisation versions, and the outer synchronising ring (24a, 24b) has driving protrusions (36a, 36b) which engage at least halfway in the web portion of the carrier. Each driving protrusion is situated in an engagement aperture (38). The synchronising ring (28, 34) immediately within the outer synchronising ring provided with locking teeth (26) has on its side facing away from the web portion of the carrier axial driving protrusions (30a, 30b) which each engage in respective adjacent coupling elements (22', 22").

Owner:SCANIA CV AB

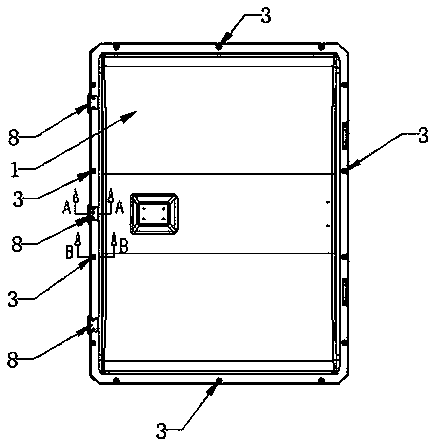

Sealing structure and method for top cover of top-mounted high-voltage equipment box of motor train unit

The invention relates to a sealing structure and method for a top cover of a top-mounted high-voltage equipment box of a motor train unit. The sealing structure comprises a box body and the top cover,wherein the top cover is connected to the box body in a sealed mode through a fastener; an outer ring sealing structure and an inner ring sealing structure are arranged between the top cover and thebox body and positioned on the two sides of the fastener respectively; and pre-pressure is applied to the outer ring sealing structure and the inner ring sealing structure through the fastener to forma double-layer sealing structure. By the adoption of the sealing structure with the outer ring sealing structure and the inner ring sealing structure arranged on the two sides of the fastener respectively, so that the sealing structure bears proper pre-pressure, and therefore a good sealing effect is achieved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

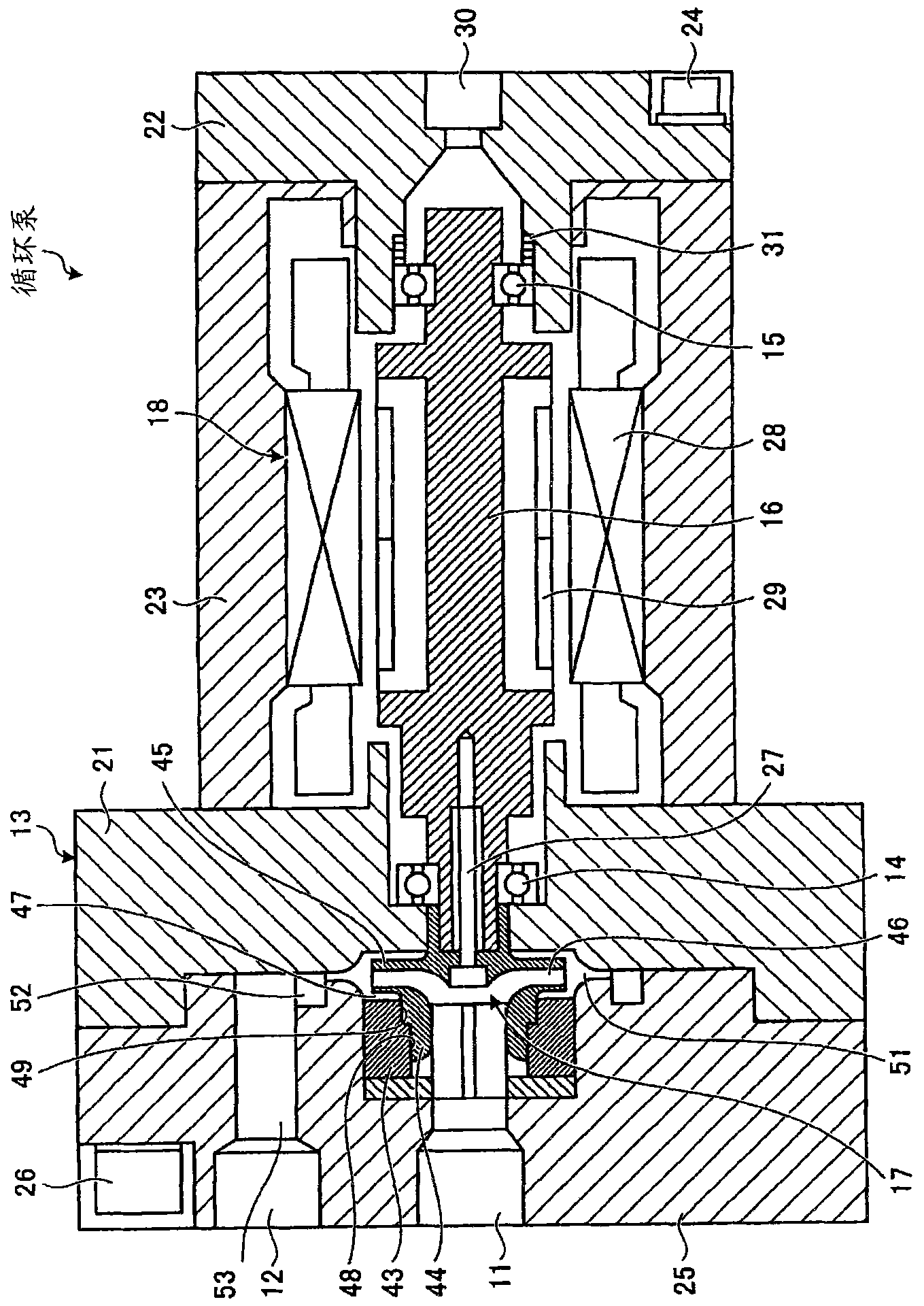

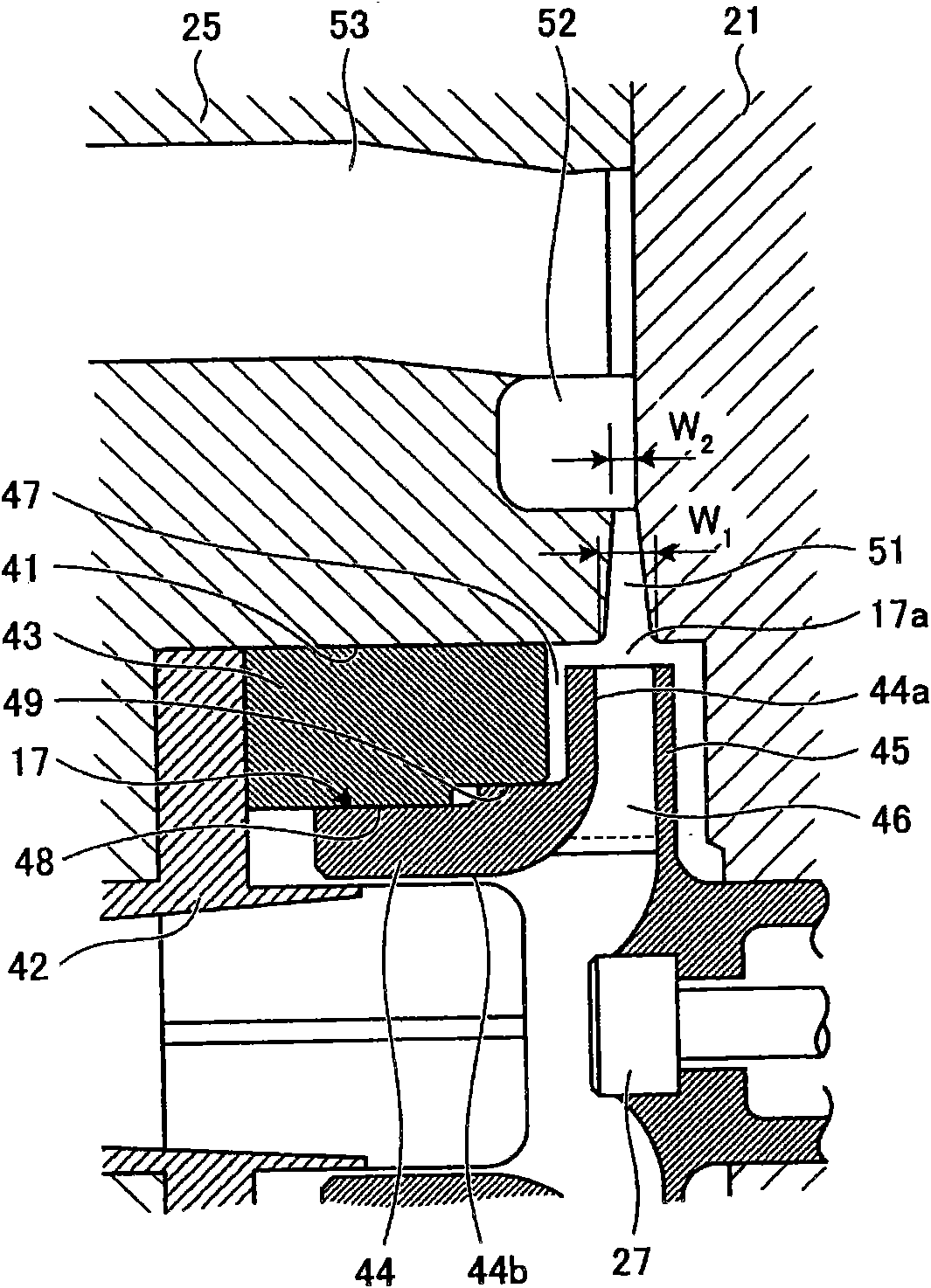

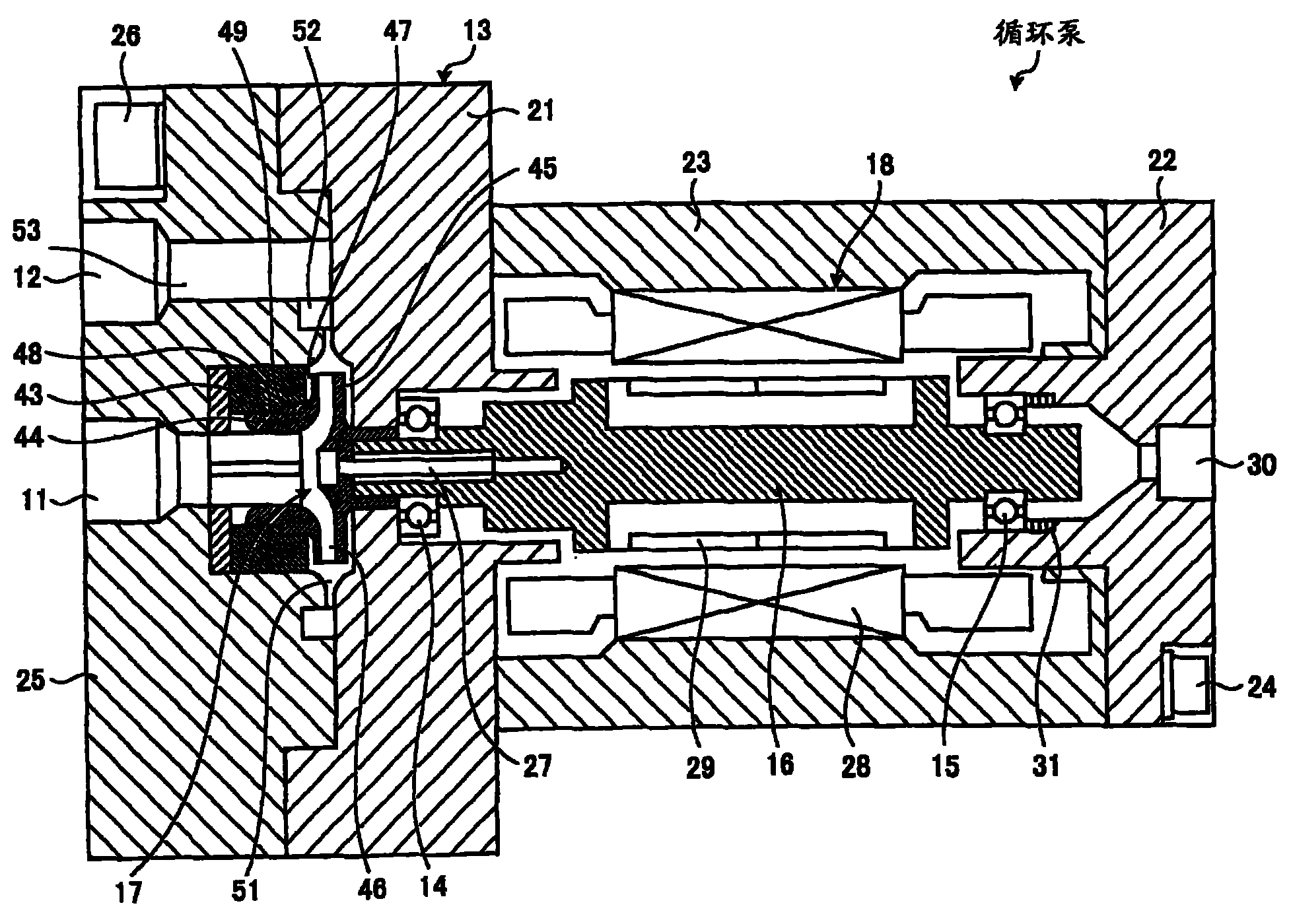

Pump

InactiveCN101960149AExtend your lifePrevent backflowSpecific fluid pumpsPump componentsImpellerBall bearing

A pump having extended life. A main shaft (16) is rotatably supported in a casing (13) by ball bearings (14, 15), and the casing (13) has a suction opening (11) and a discharge opening (12). An impeller (17) is connected to an end of the main shaft (16), and the impeller (17) can be rotated by a canned motor (18) via the main shaft (16). A front shroud (44) is provided to the axial front portion of the impeller (17), and a rear shroud (45) is provided to the axial rear portion of the impeller (17). A predetermined axial gap (47) is formed between the casing (13) and the front shroud (44). Radial seal sections (48, 49) are arranged between the casing (13) and the front shroud (44).

Owner:MITSUBISHI HEAVY IND LTD

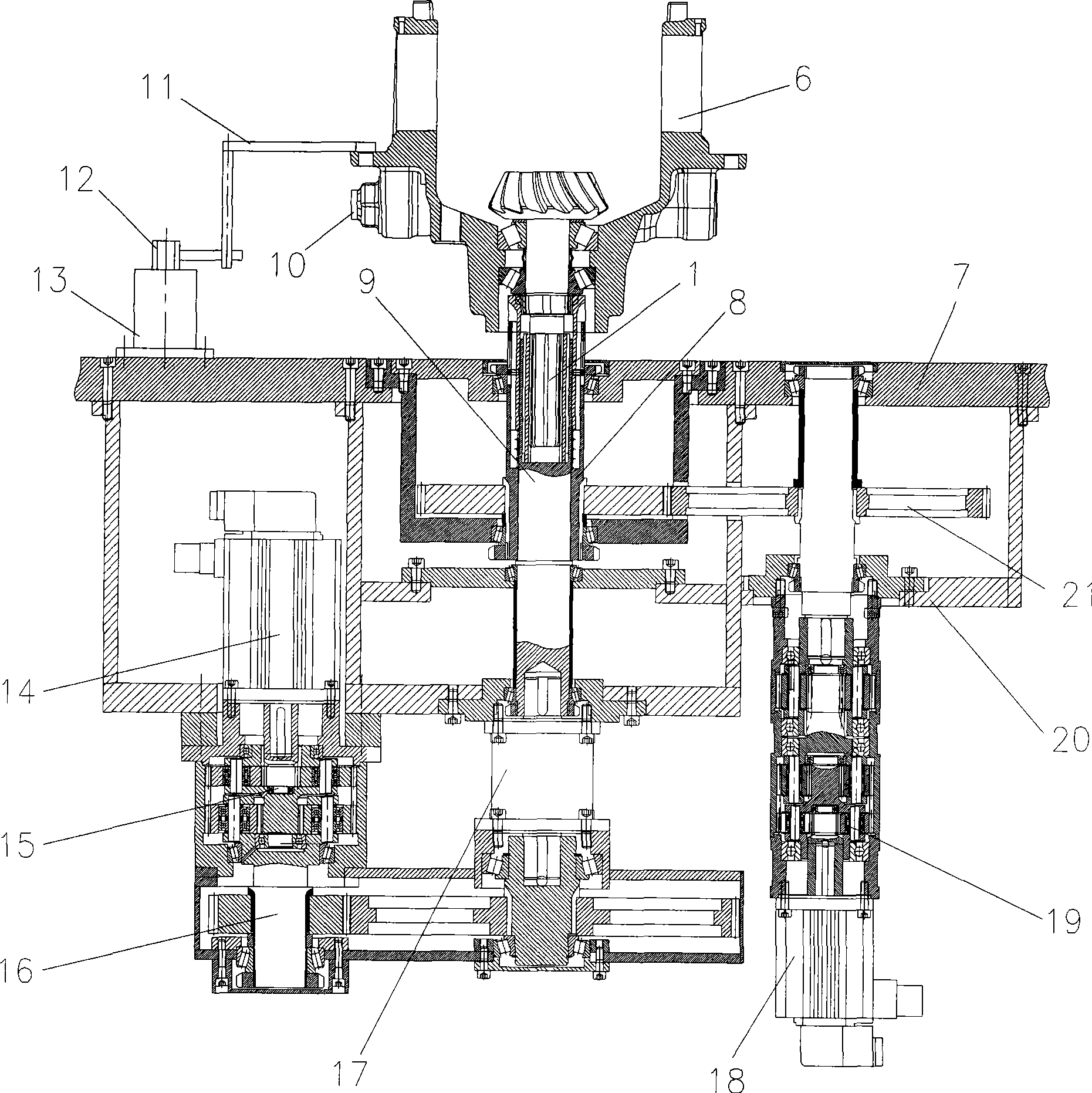

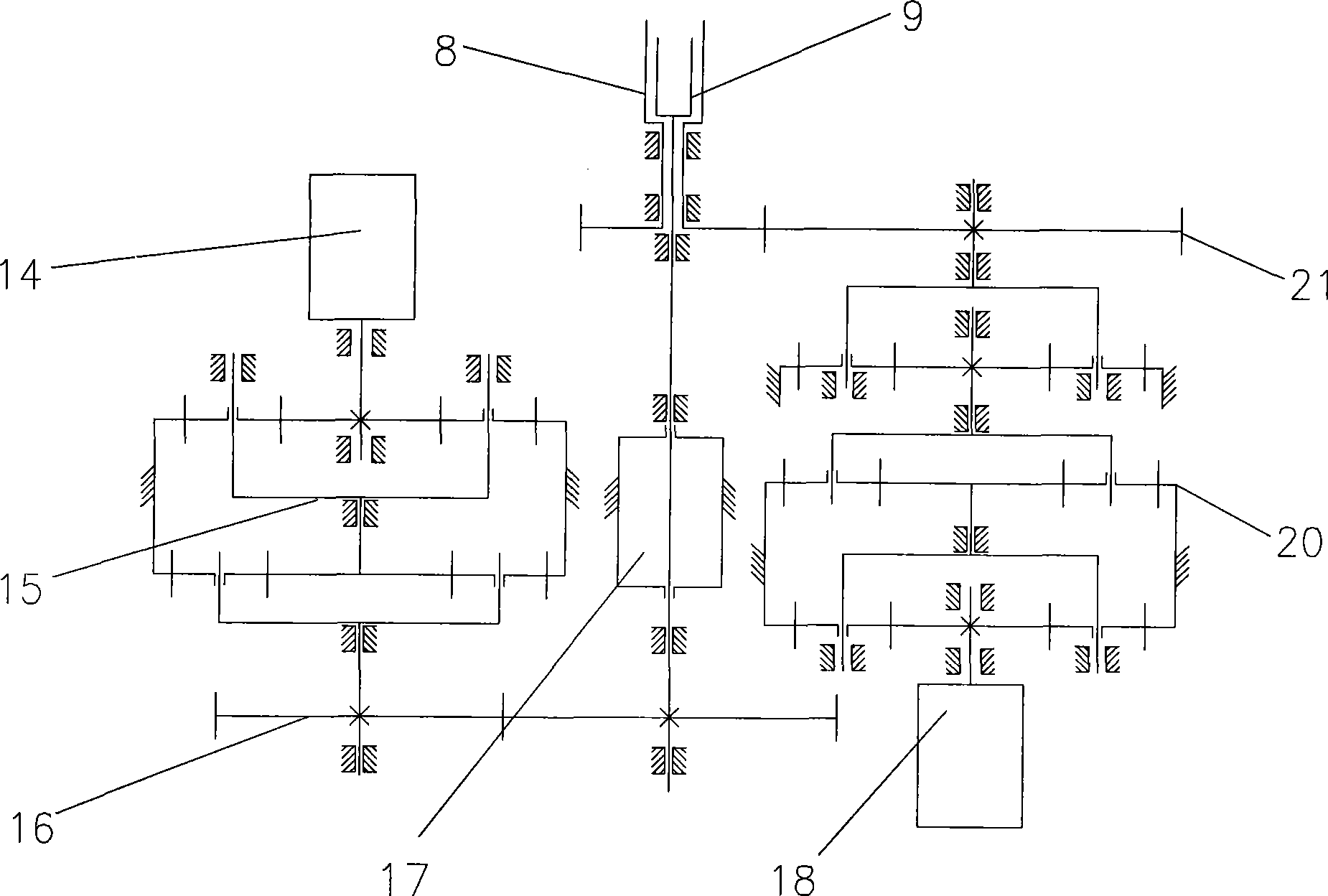

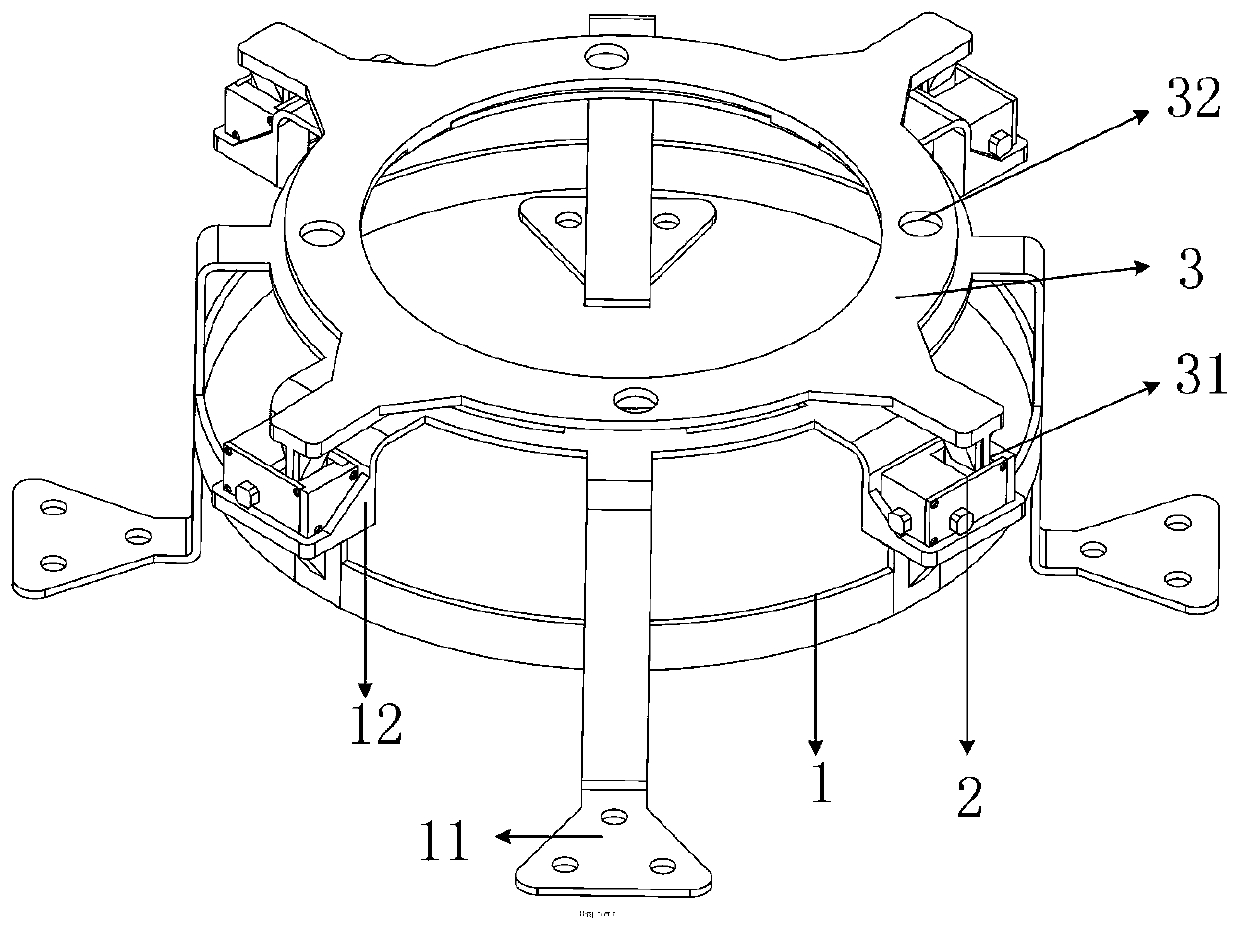

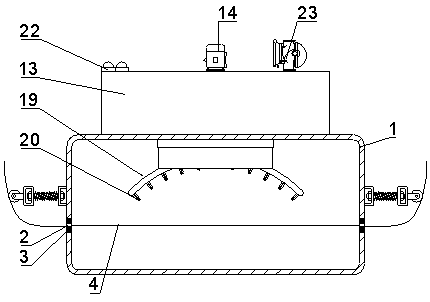

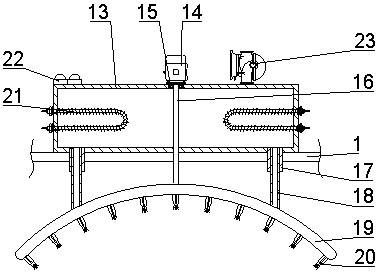

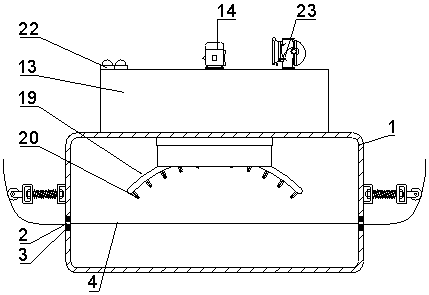

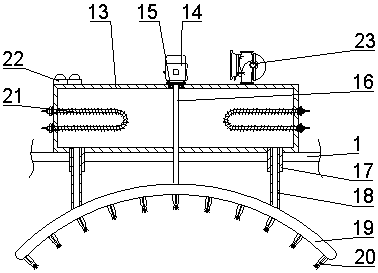

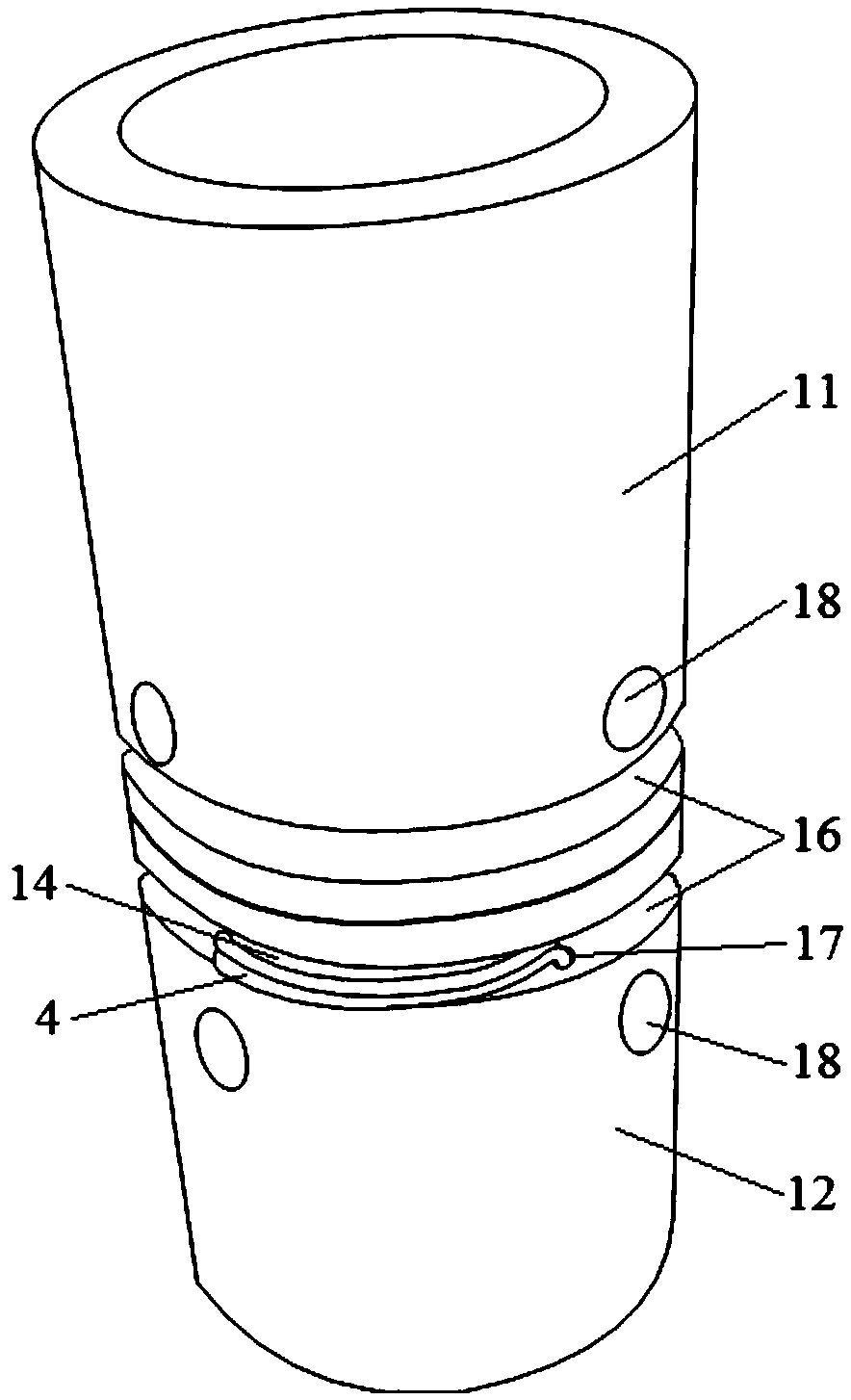

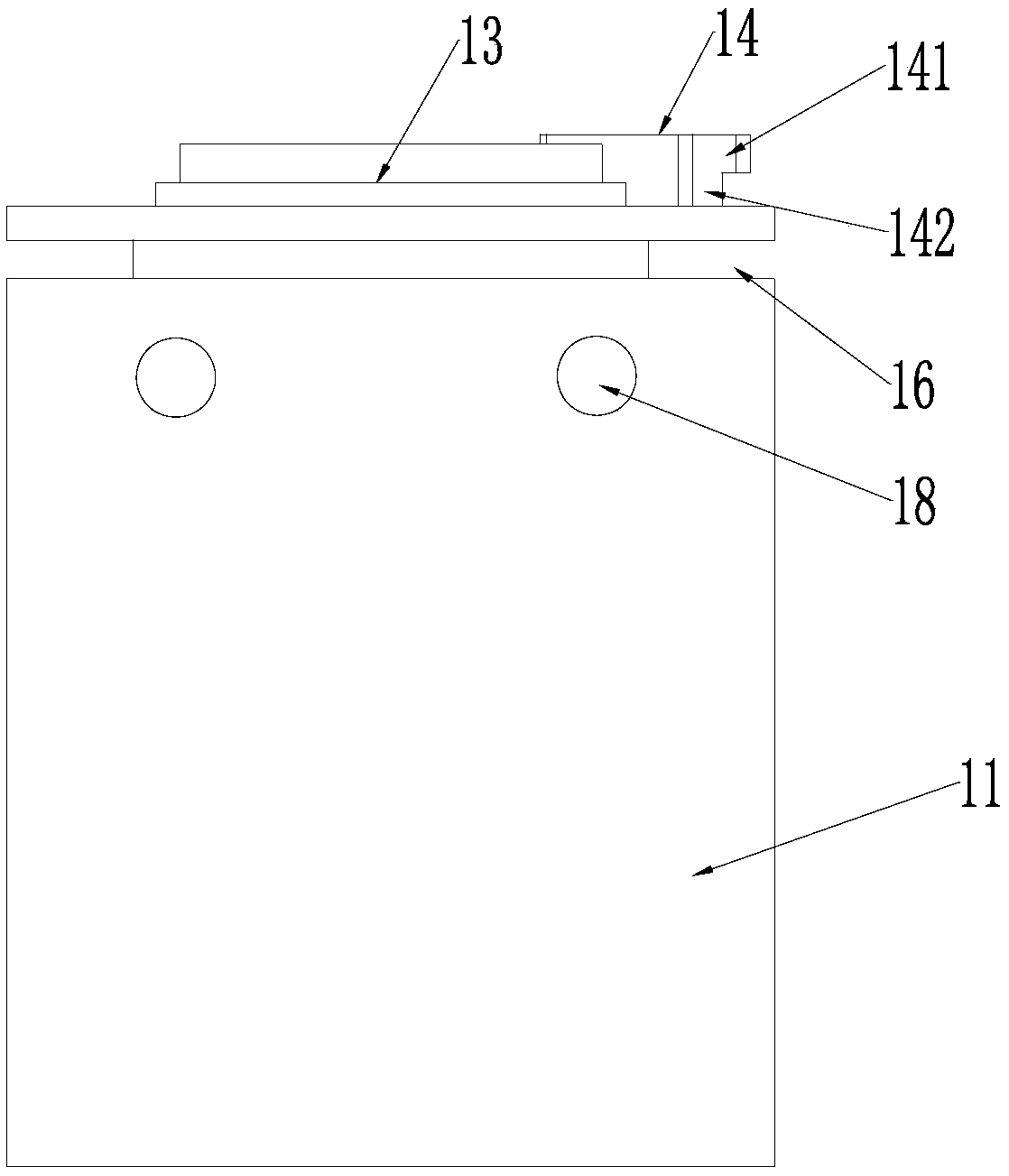

Horizontal shaft wind turbine blade self-adaptive elastic variable pitch device

InactiveCN108223273AAppropriate preloadStable power outputWind motor controlMachines/enginesSelf adaptiveAirflow

The invention discloses a horizontal shaft wind turbine blade self-adaptive elastic variable pitch device. The horizontal shaft wind turbine blade self-adaptive elastic variable pitch device comprisesa flange plate and draught fan blades; a guiding sleeve is fixed to the flange plate; a sleeve cavity matched with the guiding sleeve in a sleeved manner is machined for the draught fan blades whichare provided with a flange block; a spring damper for applying proper pre-tightening force to the draught fan blades when the inflow air speed of a wind turbine is smaller than the rated air speed isarranged in the guiding sleeve; the front end of the spring damper is fixedly connected with the flange block; the rear end of the spring damper is fixed to the flange plate; an inverted-T-shaped reversing track is arranged on the peripheral face of the guiding sleeve; a U-shaped reversing track groove matched with the inverted-T-shaped reversing track is formed in the sleeve cavity; and the draught fan blades overcome the pre-tightening force of the spring damper to complete the variable pitch action of the draught fan blades along guiding reversing of the inverted-T-shaped reversing track bymeans of the centrifugal force generated due to high-speed rotating and the pneumatic reversing torque generated on the draught fan blades by gas flow when the inflow air speed of the wind turbine islarger than the rated air speed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

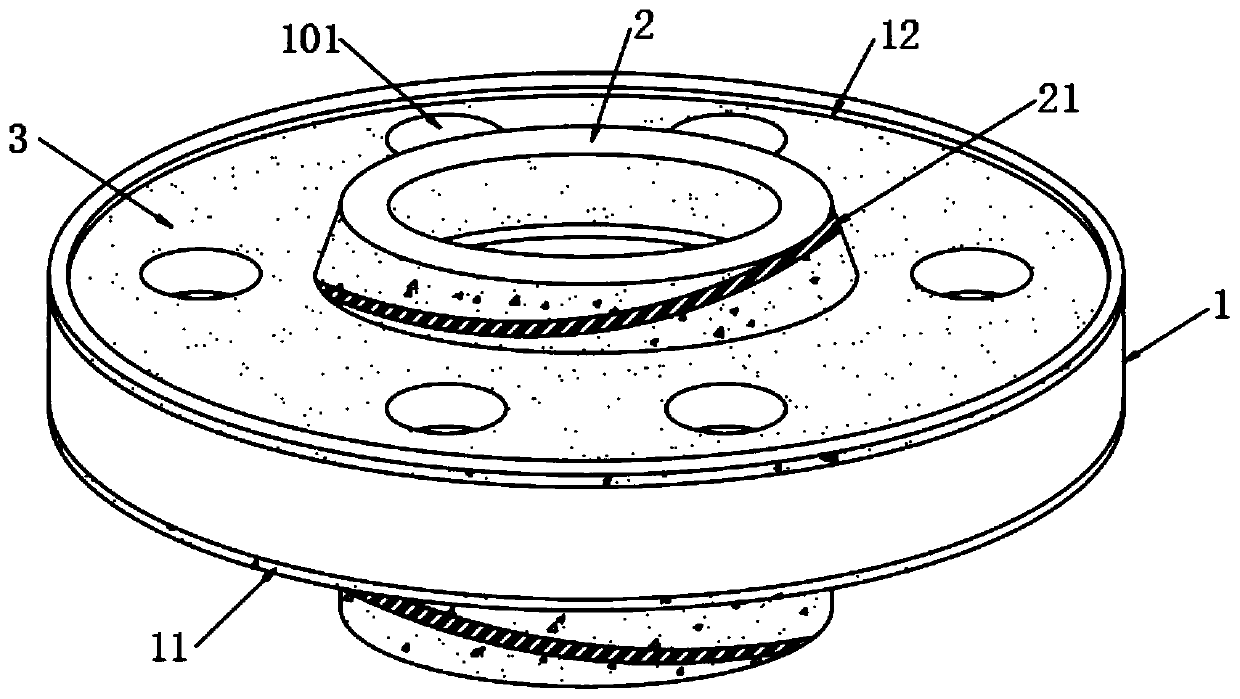

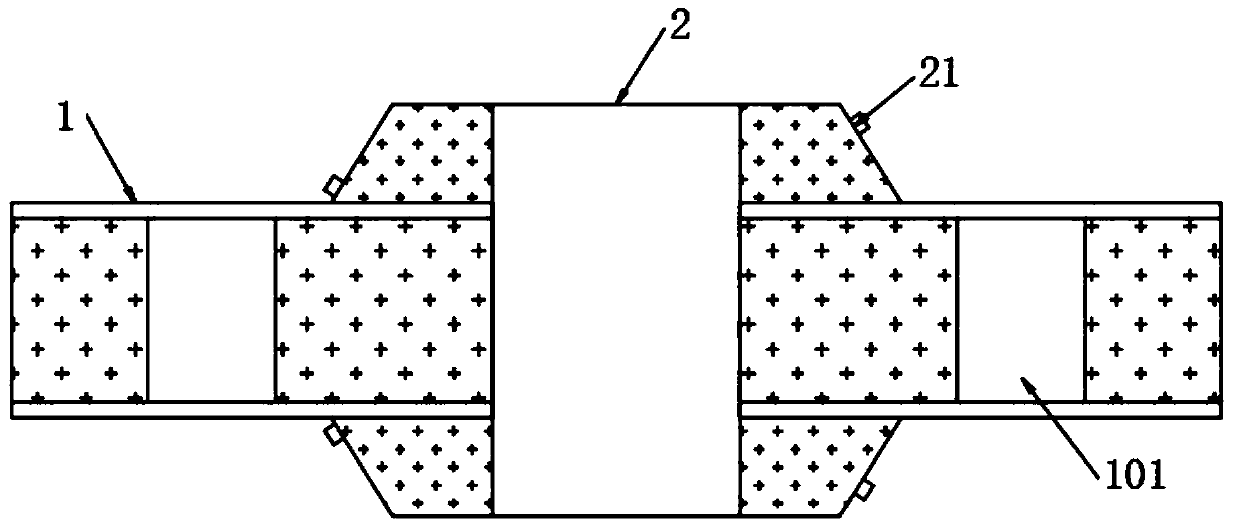

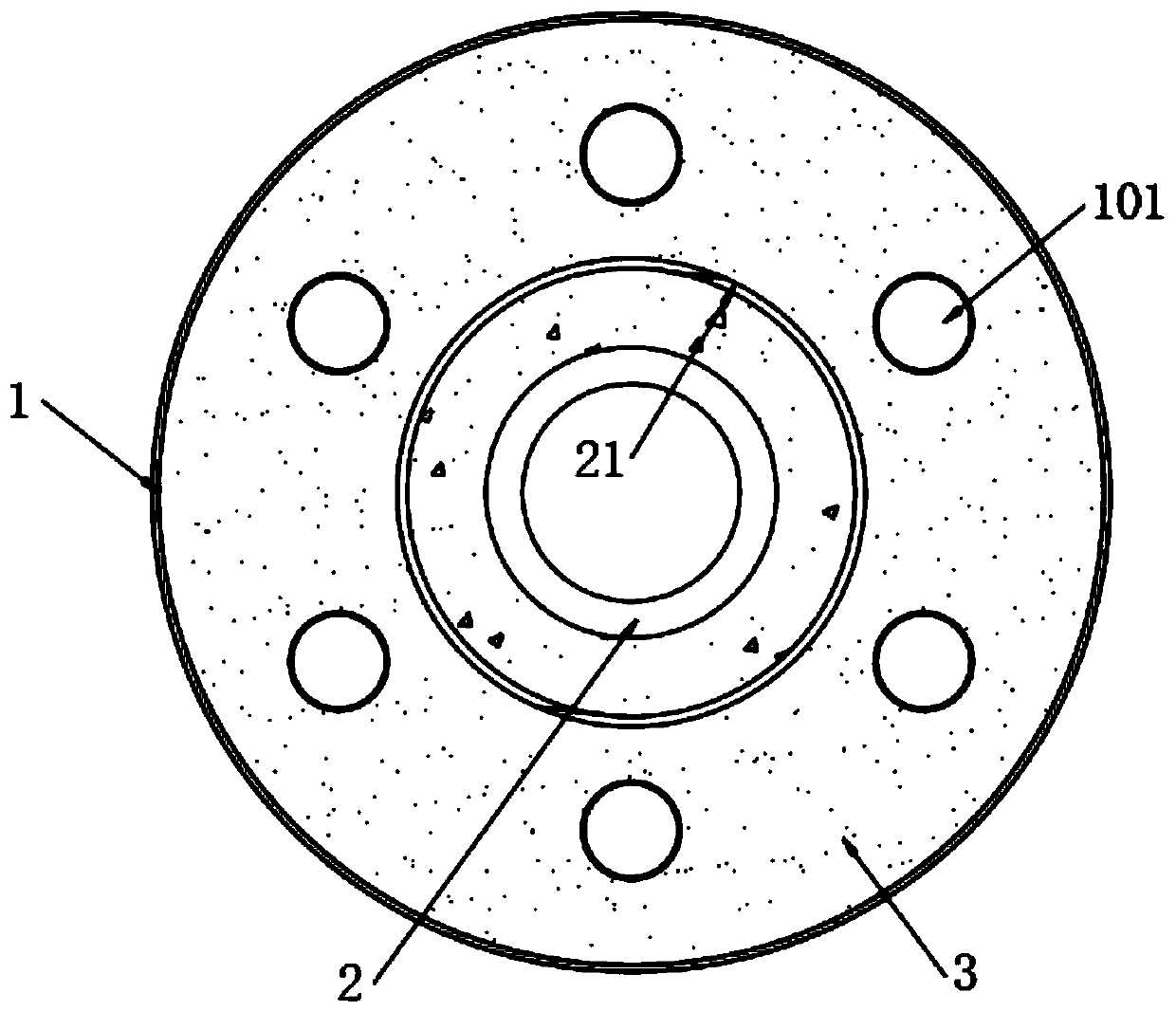

Flange for pressure vessel and machining method thereof

ActiveCN111571131APreserve the seal specific pressureImprove the stability of usePositioning apparatusMetal-working holdersClassical mechanicsScrew thread

The invention belongs to the technical field of flanges, and particularly relates to a flange for a pressure vessel and a machining method thereof. The flange for the pressure vessel comprises a flange plate. A plurality of screw holes are formed in the flange plate in a central symmetry mode, and connecting shaft columns are symmetrically and fixedly arranged in the middle of the top end of the flange and the middle of the bottom end of the flange plate correspondingly. Spirally distributed threaded protrusions are fixedly arranged on the outer walls of the connecting shaft columns. The limiting grooves are integrally formed in the top end and the bottom end of the flange plate. Through the combination of the threaded protrusions and the limiting grooves, the surface, making contact withthe flange plate, of a gasket can be clamped into one limiting groove when the sealing gasket is installed, a threaded groove matched with the corresponding threaded protrusion is formed in the innerwall of the gasket, and the connecting stability between the gasket and the corresponding connecting shaft column is enhanced. The gasket and the flange plate are in tight contact and are not prone toloosening and slipping, proper pre-tightening force is formed between the flange plate and the gasket, it can be guaranteed that certain sealing specific pressure can be kept when the gasket works, and the use stability of the gasket is enhanced.

Owner:海盐县法兰厂

hydraulic pump

ActiveCN107429676BInhibit wearAppropriate preloadRolling contact bearingsPositive displacement pump componentsHydraulic pumpEngineering

The present invention provides a hydraulic pump having a rotating shaft supported so as to be rotatable relative to a housing, the hydraulic pump comprising: bearings provided on one end side and the other end side of the rotating shaft, at least one of the sides is a first annular member provided around the rotation shaft, the bearing portion on one side has a support portion for rotatably supporting the rotation shaft, and a preload applying member for applying a preload in the axial direction to the support portion, In the axial direction, a first annular member is interposed between the one bearing portion and the support seat of the rotary shaft, and the inner diameter of the first annular member is larger than the diameter of the rotary shaft.

Owner:TOYOTA IND CORP

A macro-micro-driven linear piezoelectric motor and its driving method

InactiveCN103281005BImplement macro and micro driversSimple processPiezoelectric/electrostriction/magnetostriction machinesElastomerPhase difference

The invention discloses a macro and micro-driving type linear piezoelectric motor and a driving method thereof, and relates to the field of the ultrasonic motor and micro driving. The motor comprises a rack, a driving vibrator, an active cell and a pre-tightening mechanism, wherein the driving vibrator comprises a metallic elastomer, a micrometric displacement amplification elastomer and a piezoelectric element; the two symmetrical convex teeth on the inner side of the micrometric displacement amplification elastomer are in frictional contact with the active cell; and the piezoelectric element is polarized along the thickness direction. The motor macro driving method is characterized in that two longitudinal standing waves of which the phase difference is 90 degrees, the frequencies are closed, and the type are the same are stimulated by the vibrator under the action of the alternating current of which the phase difference is 90 degrees; after the standing waves are combined, an elliptic movement locus is formed on the convex tooth part; and under the pre-tightening force action, the active cell generates the macro linear movement. According to the micro-driving method, direct-current high voltage is applied to the piezoelectric element, the vibrator generates static deformation, and the two symmetrical convex teeth on the inner side of the micrometric displacement amplification elastomer clamp the active cell and the micro linear movement is generated. According to the invention, the macro driving and the micro driving are simultaneously realized on one motor, and the invention has the characteristics of simple structure and reliability in working.

Owner:SOUTH CHINA AGRI UNIV

Foam fixed hot melt device

The invention discloses a hot melting device for fixing foam. The hot melting device comprises a workbench, wherein a vaulted boss is arranged on the workbench; a lifting device is arranged above the boss; and the lower surface of the lifting device is connected with a hold-down device, a heating device and a cooling device. A loudspeaker is arranged and located on the boss on the surface of the workbench, the lifting device is regulated so that the hold-down device pushes tightly against the loudspeaker and prevents the loudspeaker from moving, a plastic rod fixed with a loudspeaker casing and the foam penetrating through the plastic rod are arranged on the surface of the loudspeaker, a gasket penetrating through the plastic rod is arranged above the foam, and the plastic rod is heated by the heating device, melt and attached on the surface of the gasket to prevent the foam from moving, and cooled by the cooling device.

Owner:INPLAST PLASTIC & ELECTRONICS SUZHOU CO LTD

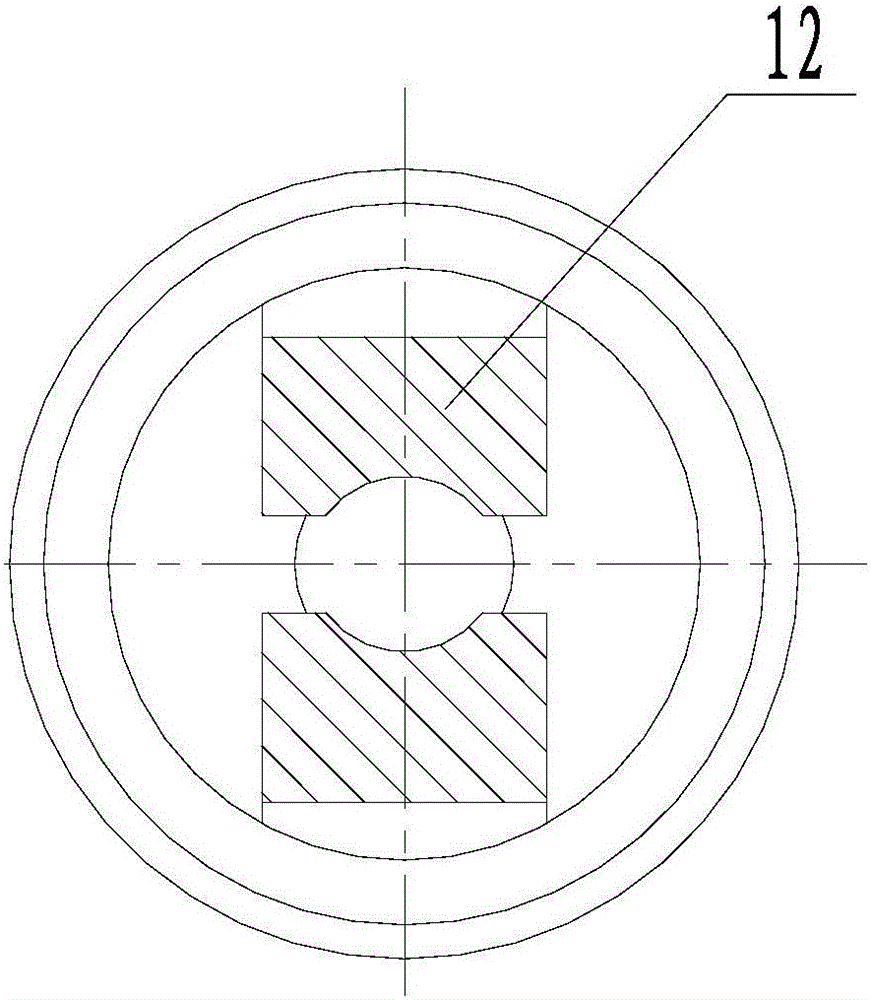

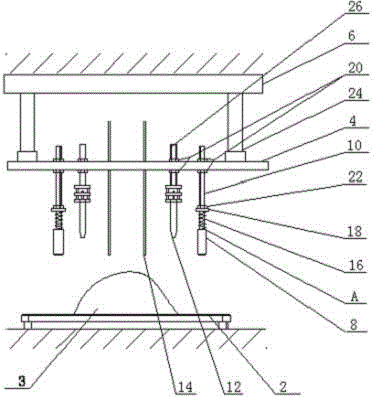

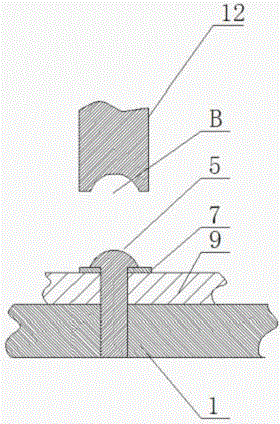

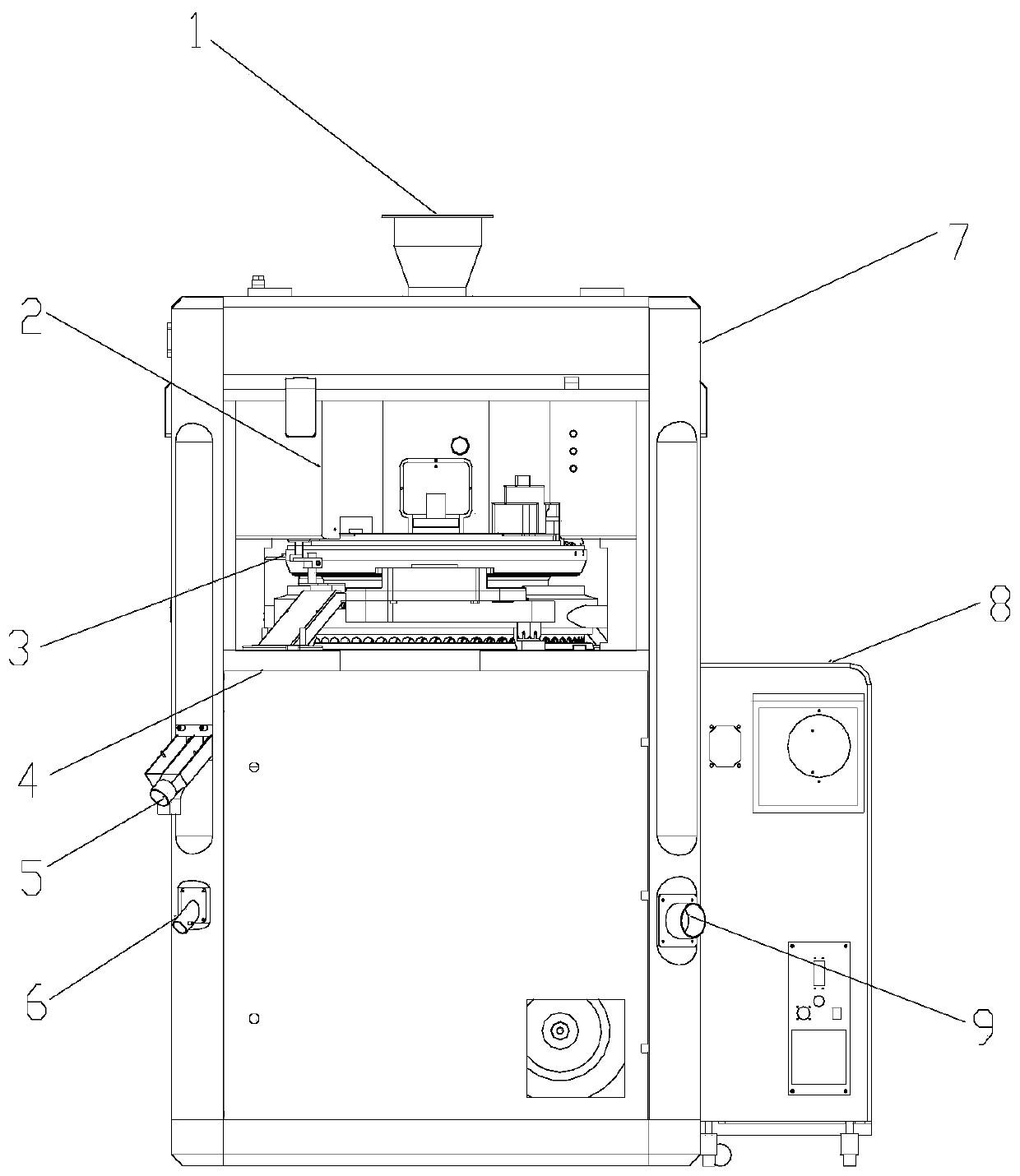

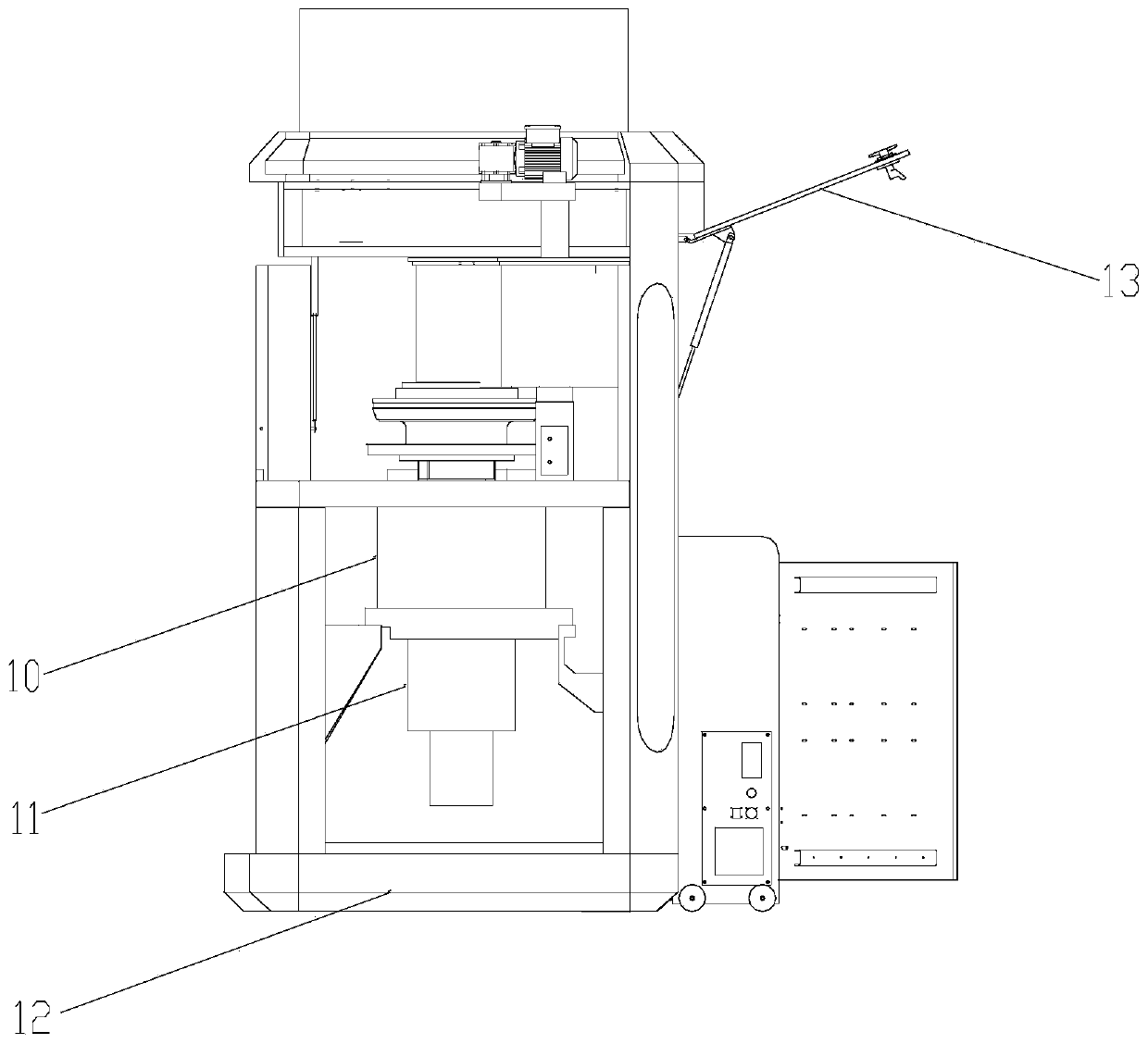

High-speed powder tablet press

The invention discloses a high-speed powder tablet press. The high-speed powder tablet press comprises a rack and a rotating mechanism installed at the bottom of the rack. A top tower capable of ascending and descending is installed at the top of the rack. A rotating tower driven by the rotating mechanism to rotate is arranged below the top tower. An upper rail is installed on the lower portion ofthe top tower. A lower rail is installed on a workbench on the lower portion of a lower tower. A punch of an upper punch and a punch of a lower punch are kept in arc-shaped guide grooves in the upperrail and the lower rail correspondingly. A punch rod of the upper punch and a punch rod of the lower punch penetrate through an upper guide hole of the upper tower and a lower guide hole of the lowertower correspondingly and oppositely stretch into a middle die hole of a middle die. The upper punch and the lower punch rotate along with the rotating tower and do vertical reciprocating motion in the upper guide hole and the lower guide hole according to a rotating path formed by the upper rail and the lower rail. The upper punch and the lower punch do combined motion, and punching of medicinepowder in the middle die is completed under the pressure action of a pre-pressing wheel and a main pressing wheel. The high-speed powder tablet press is high in operation efficiency, the resonance phenomenon cannot be generated, and it can be ensured that the medicine powder is sufficiently extruded and formed in the high-speed rotating process.

Owner:HUBEI UNIV OF TECH

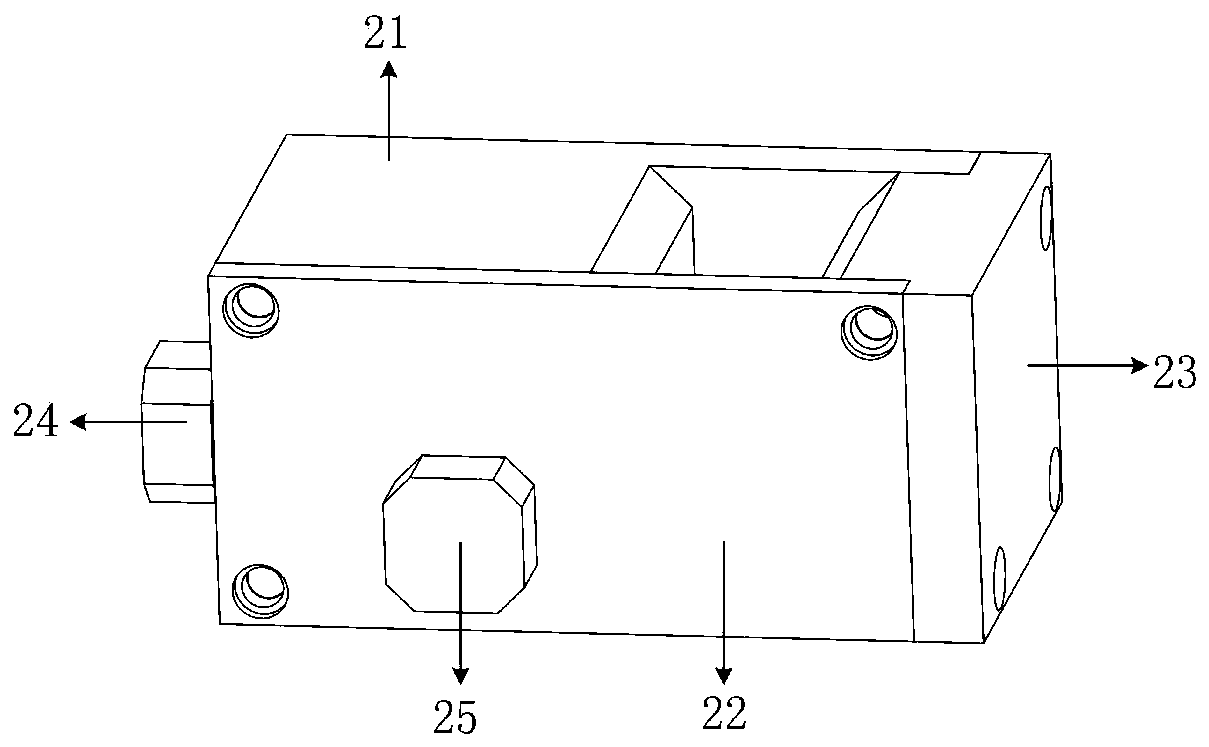

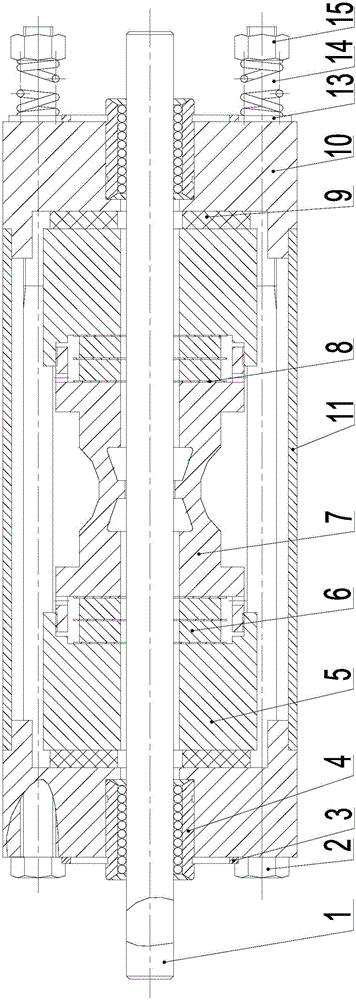

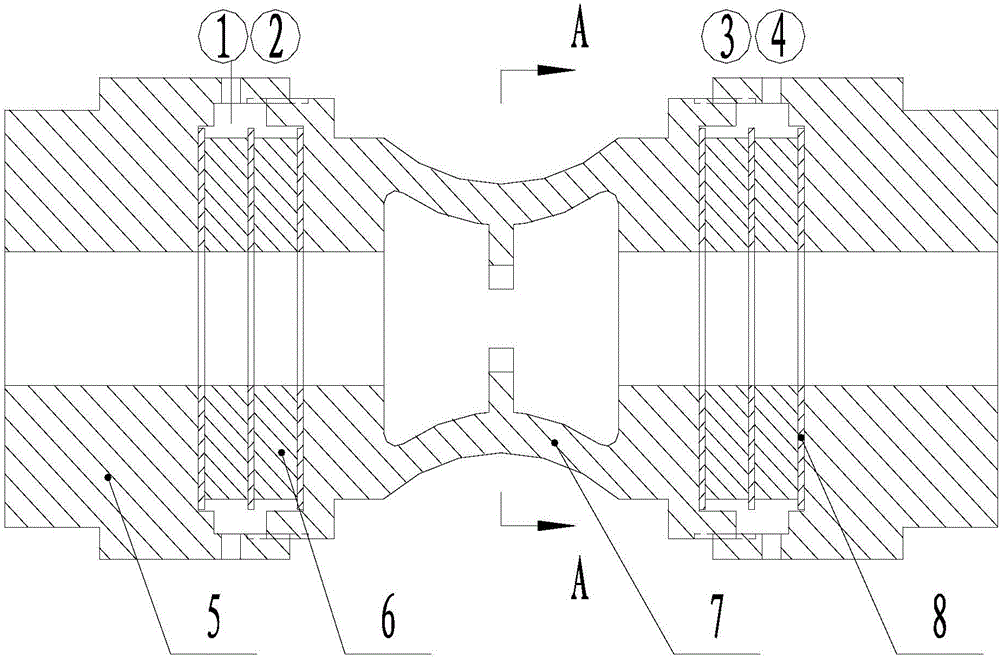

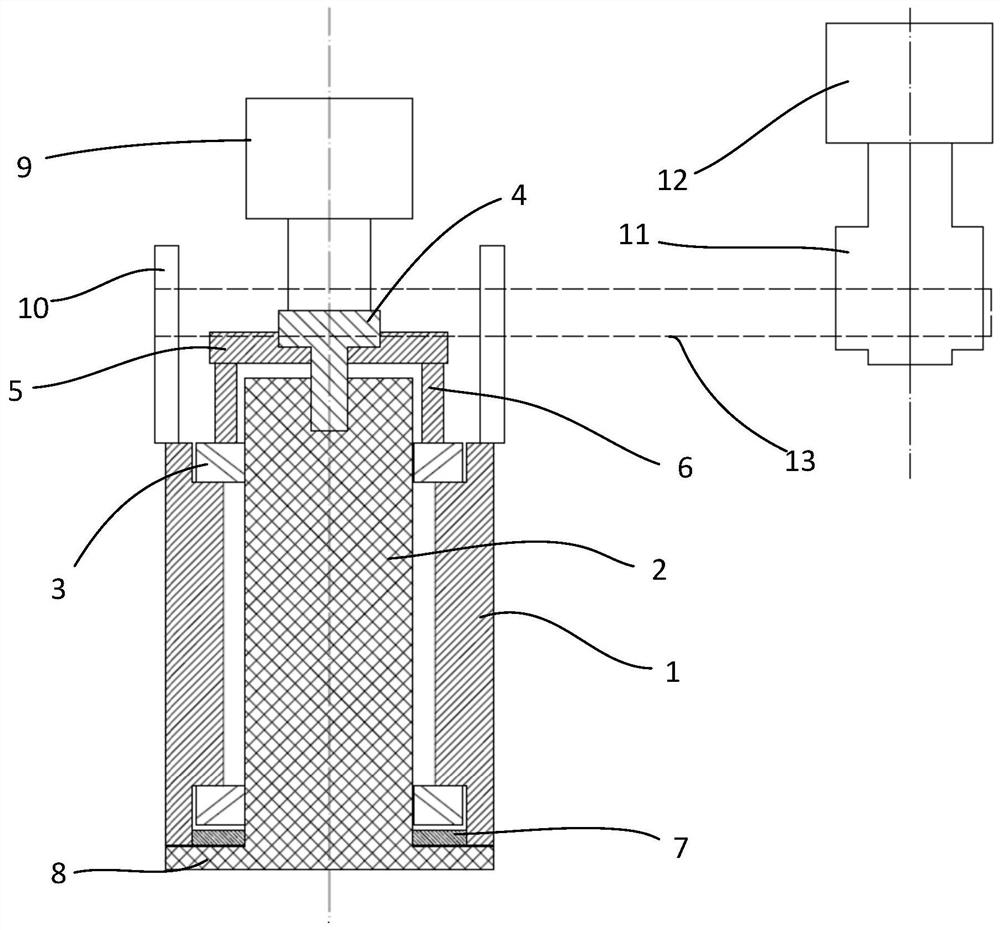

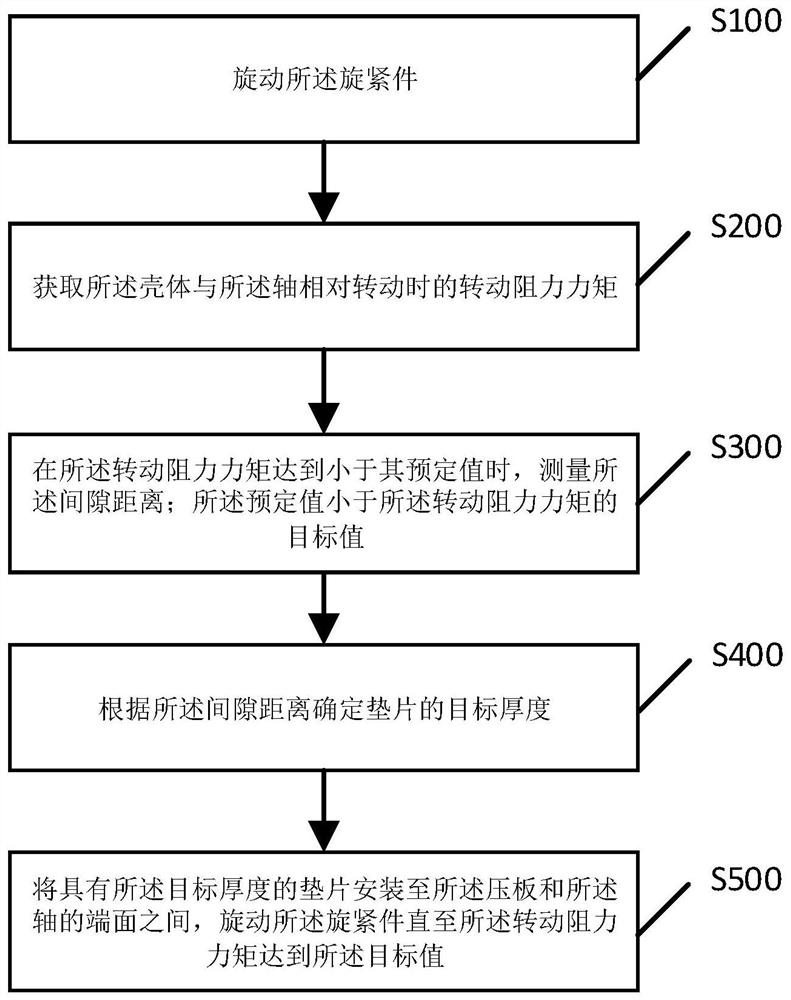

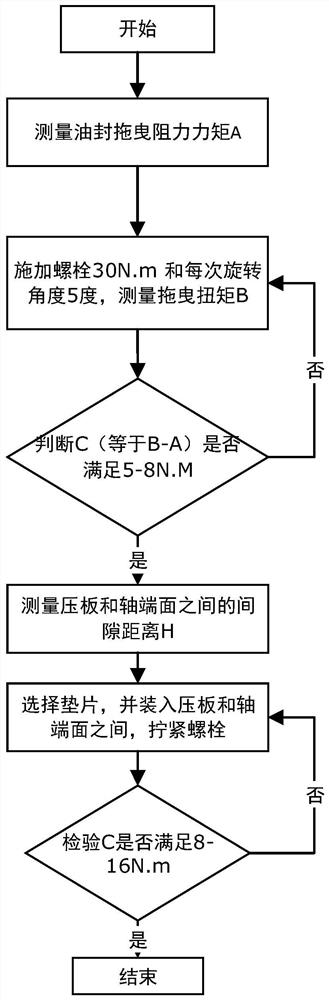

Loading method, loading equipment and installation method of rolling bearing pretightening force

ActiveCN111173843BAssembly precisionAppropriate preloadBearing assemblyShaftsRolling-element bearingResistance force

The application discloses a loading method, loading equipment and installation method of a rolling bearing pretightening force. Wherein, the rolling bearing is arranged between the shaft and the housing; one end of the shaft has a tightening member and a pressure plate; the gap distance between the pressure plate and the end surface of the shaft is changed by turning the tightening member ; Wherein, the loading method of the rolling bearing pretightening force includes the following steps: rotating the tightening member; obtaining the rotational resistance torque when the housing rotates relative to the shaft; when the rotational resistance torque reaches less than its When the predetermined value is reached, measure the gap distance; the predetermined value is less than the target value of the rotational resistance moment; determine the target thickness of the gasket according to the gap distance; install the gasket with the target thickness on the pressure plate and between the end surface of the shaft, the tightening member is rotated until the rotational resistance torque reaches the target value. The application can apply proper pre-tightening force to the bearing during the axle assembly process.

Owner:JOHN DEERE TIANJIN

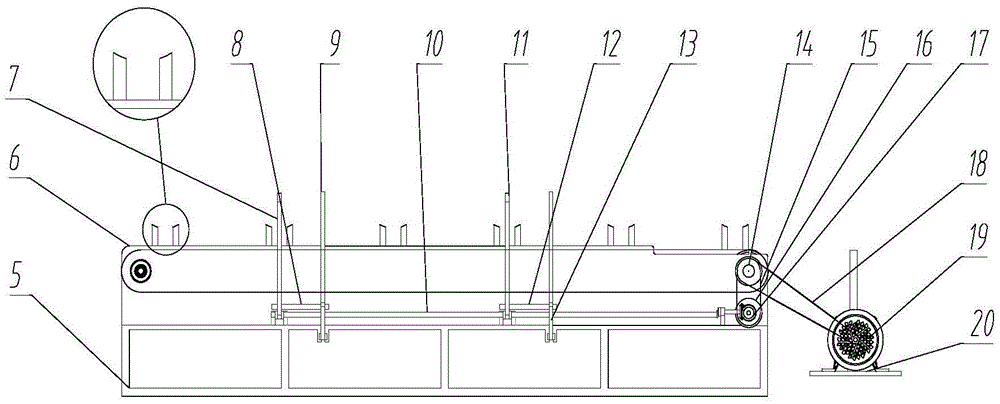

A es fiber spunlace non-woven flexo printing machine

InactiveCN108547092BGuaranteed tensionAdjust the preloadLiquid/gas/vapor removal by gas jetsPolymer scienceHeater Rod

The invention discloses an ES fiber spunlace non-woven fabric rotary flexo press, and relates to the technical field of non-woven fabric processing. The ES fiber spunlace non-woven fabric rotary flexopress comprises a box body. Feed and discharge ports are formed in the wall bodies of the two sides of the box body respectively. The surfaces of the left side and the right side of the box body arefixedly connected with C-shaped frames respectively, thread columns movably penetrate through the C-shaped frames, and first nuts are screwed into the portions, located in the C-shaped frames, of thethread columns. Through the effect of a gas compression pump, the pressure intensity of gas in a drying box is improved, through the effect of electric heating rods, hot gas located in the drying boxenters a sprayer through hollow annuluses and is finally sprayed out through nozzles, thus, non-woven fabric raw materials in the feed and discharge ports are dried, and as the sprayer is in a rotarystate, the drying uniformity is improved. By adjusting the first nuts and second nuts, the pre-tightening force of spiral springs can be rapidly adjusted, thus, the non-woven fabric raw materials haveproper pre-tightening force after entering the box body, the non-woven fabric raw materials are kept in a tensioned state, and the drying effect is improved.

Owner:JIAN CITY SANJIANG SUPERFINE FIBER NONWOVEN

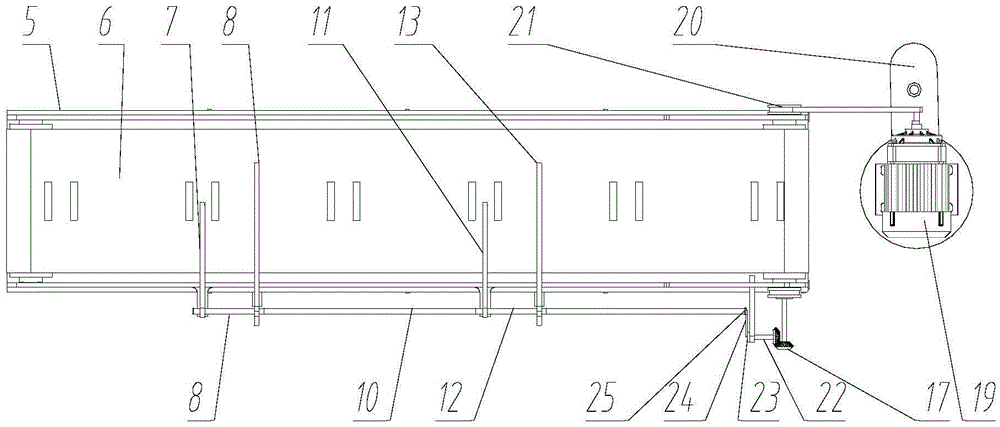

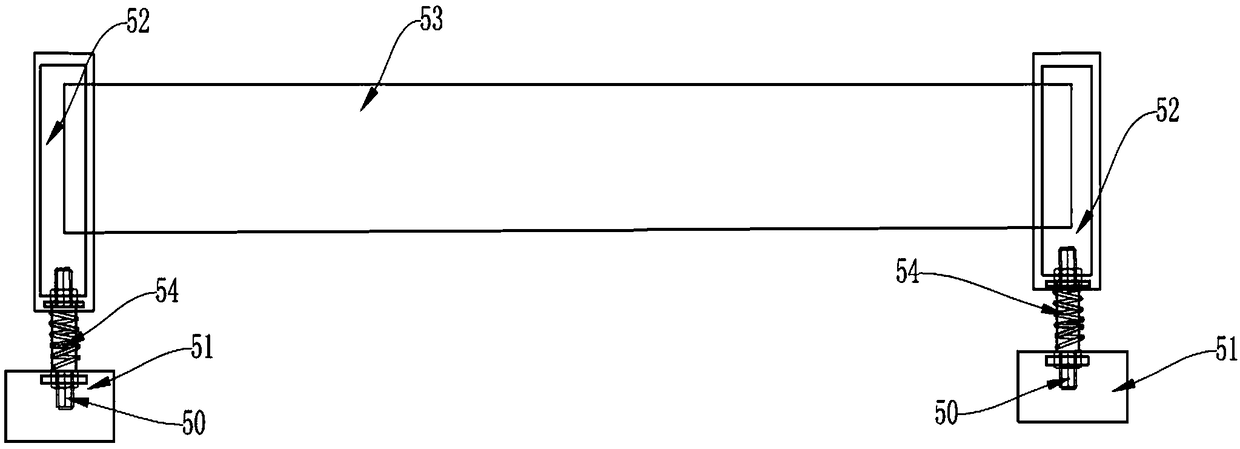

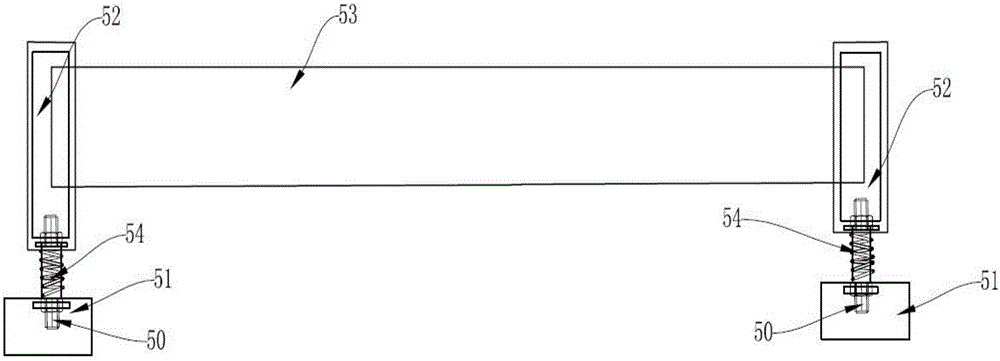

A cardboard forming device with guide rollers

ActiveCN106182905BAvoid breakageReduce entryMechanical working/deformationPaper-making machinesCardboardEngineering

A paperboard forming device with a guide roller comprises a rack, a forming cylinder, a conveying roller table, a grooved roller and a guide roller device. The grooved roller is arranged under the forming cylinder, and makes contact with and presses the forming cylinder to form a first contact face A. The guide roller device is fixed to a pedestal and is parallel to the radial direction of the forming cylinder; the guide roller device makes contact with and presses the forming cylinder to form a second contact face B; and the guide roller device comprises two bases, two bearing seats and the guide roller. The two bases are symmetrically fixed to the pedestal; the two sides of each bearing seat are connected with the corresponding bases through guide rods; the guide rods between the bearing seats and the bases are sleeved with springs; and the two ends of the guide roller are rotatably arranged on the two bearing seats. The paperboard forming device achieves the pre-pressing effect of the forming cylinder on paperboards; paper layers are twined and attached more compactly; the height of the guide roller device can be adjusted to guarantee the effective contact between the guide roller device and the forming cylinder, and proper pre-pressure is kept; and the roller pressing effect is good, the application range is wide, the adjustability is high, the fault rate is low, and continuous production is achieved.

Owner:GUANGDONG WALKKIND SPECIAL FIBERBOARD TECH

ES fiber spunlace non-woven fabric rotary flexo press

InactiveCN108547092AImprove uniformityImprove drying effectLiquid/gas/vapor removal by gas jetsCompression PumpWoven fabric

Owner:JIAN CITY SANJIANG SUPERFINE FIBER NONWOVEN

Paperboard forming device with guide roller

A paperboard forming device with a guide roller comprises a rack, a forming cylinder, a conveying roller table, a grooved roller and a guide roller device. The grooved roller is arranged under the forming cylinder, and makes contact with and presses the forming cylinder to form a first contact face A. The guide roller device is fixed to a pedestal and is parallel to the radial direction of the forming cylinder; the guide roller device makes contact with and presses the forming cylinder to form a second contact face B; and the guide roller device comprises two bases, two bearing seats and the guide roller. The two bases are symmetrically fixed to the pedestal; the two sides of each bearing seat are connected with the corresponding bases through guide rods; the guide rods between the bearing seats and the bases are sleeved with springs; and the two ends of the guide roller are rotatably arranged on the two bearing seats. The paperboard forming device achieves the pre-pressing effect of the forming cylinder on paperboards; paper layers are twined and attached more compactly; the height of the guide roller device can be adjusted to guarantee the effective contact between the guide roller device and the forming cylinder, and proper pre-pressure is kept; and the roller pressing effect is good, the application range is wide, the adjustability is high, the fault rate is low, and continuous production is achieved.

Owner:GUANGDONG WALKKIND SPECIAL FIBERBOARD TECH

Multi-station flexible hairy crab shaping and binding all-in-one machine and its use method

ActiveCN105539912BReasonable allocation of assembly line workImprove productivityConveyorsBinding material applicationEngineeringSelf adaptive

The invention discloses a multi-station flexible hairy crab shaping and binding integrated machine and a use method thereof. The shaping and binding integrated machine adopts a four-station system to work, and the first station is a transportation straightening device and a flexible adaptive fixed hairy crab grabbing device. The joint, the second station is the joint of the horizontal rope-tying device and the flexible adaptive fixed hairy crab grasping device, the third station is the joint of the longitudinal rope-tying device and the flexible adaptive fixed hairy crab grasping device, the first The four stations are the final packing positions. The flow operation of the four-station system reduces the cost of labor and at the same time adjusts the action time of each station to achieve the optimal design of the system and further improve work efficiency; The cross tying rope is changed to two ropes. The hairy crabs' legs are firmly bound with the horizontal tying rope first, and then the longitudinal tying rope is used for another fixed binding to ensure the firmness of the binding.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Tensioning method of belt of air-conditioning compressor of small excavator air

ActiveCN102817981BAppropriate preloadGuarantee and improve reliabilityGearingEngineeringAir conditioning

The invention provides a tensioning method of a belt of an air-conditioning compressor of a small excavator. which is characterized by comprising the following steps of: firstly, regulating a belt according to the horizontal direction of a compressor bracket assembly to enable a compressor clutch belt slot, an engine belt slot and a tension pulley belt slot to be kept on the same horizontal plane; and then, regulating the belt in the vertical direction by a tension pulley assembly to ensure that the belt has corresponding pretightening force. According to the tensioning method of the belt of the air-conditioning compressor of the small excavator, provided by the invention, the defects of the prior art are overcome, the device structure is compact, the belt is convenient to disassemble, assemble and regulate, and the reliability of an air-conditioning refrigeration system is improved.

Owner:龙工(上海)挖掘机制造有限公司

Differential screwed loader main cone pretightening force measuring set and method

InactiveCN101419106BRealize detectionAccurate measurementMeasurement of torque/twisting force while tighteningFriction torqueDifferential screw

The invention relates to a device and a method for measuring the pretightening force of a main cone of a loader based on differential speed tightening, which is characterized in that the measuring device is provided with a work top, a sleeve, an inner spline, a transmission line 1, a transmission line 2, and a pretightening moment measuring mechanism, wherein the work top is taken as a preassembling bench of the main cone and a bearing pedestal and a bearing pretightening moment measuring bench; the sleeve is matched with an opening of a locknut and used for screwing up the locknut; the innerspline is matched with an outer spline on the tail of the main cone and used for driving the main cone to rotate; the transmission line 1 takes a servomotor as a driving piece and the inner spline asa driven piece; and the transmission line 2 takes a servomotor as a driving piece and a sleeve as a driven piece. The method adopts the means of differential speed tightening to well realize detection of the starting friction torque.

Owner:HEFEI UNIV OF TECH

A long metal filter bag docking structure and its auxiliary installation tool and installation method

InactiveCN107009321BSimple structureEasy to operateDispersed particle filtrationMetal-working hand toolsButt jointAxial symmetry

Owner:XIAMEN UNIV TAN KAH KEE COLLEGE

A connecting device for mounting and dismounting a hub cover

ActiveCN110667303BReduce volumeCompact structureWheel protectionStructural engineeringMechanical engineering

Owner:YANSHAN UNIV

Differential housing and production method

Owner:SONA BLW PRAZISIONSSCHMIEDE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com