A long metal filter bag docking structure and its auxiliary installation tool and installation method

A technology for metal filter bags and installation tools, applied in separation methods, manufacturing tools, chemical instruments and methods, etc., can solve the problems of difficult to ensure the coaxiality of the filter bags, problems of sealing, insufficient pre-tightening force, etc., and achieve disassembly. Simple and fast, increased torque, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

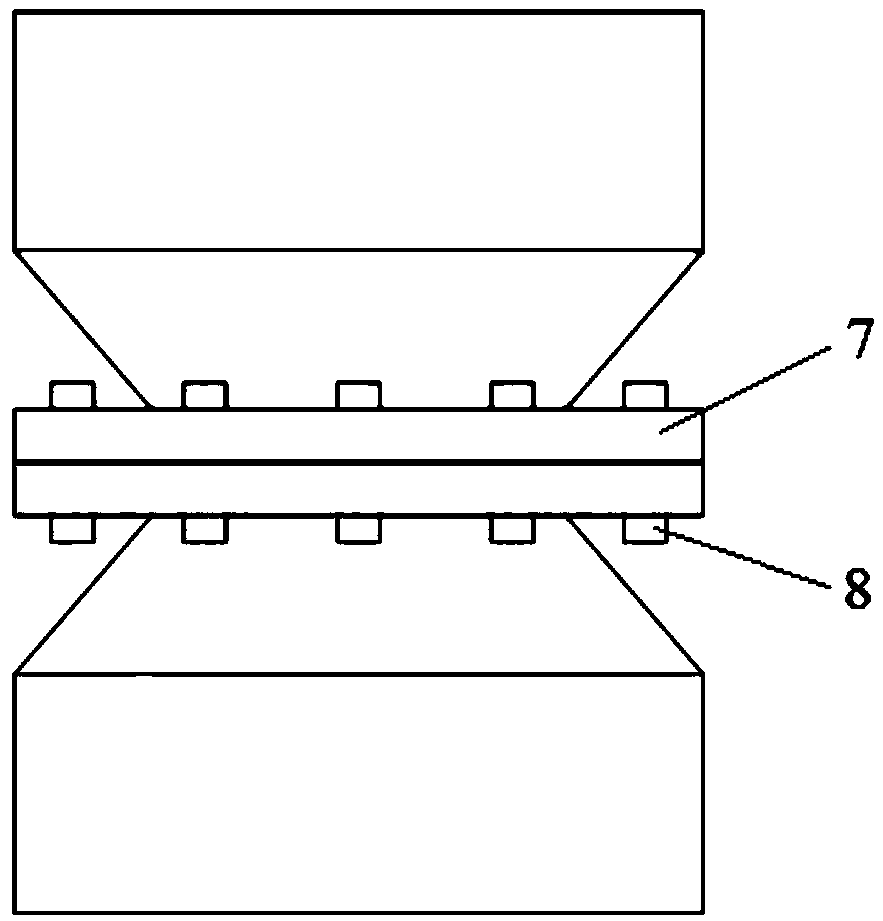

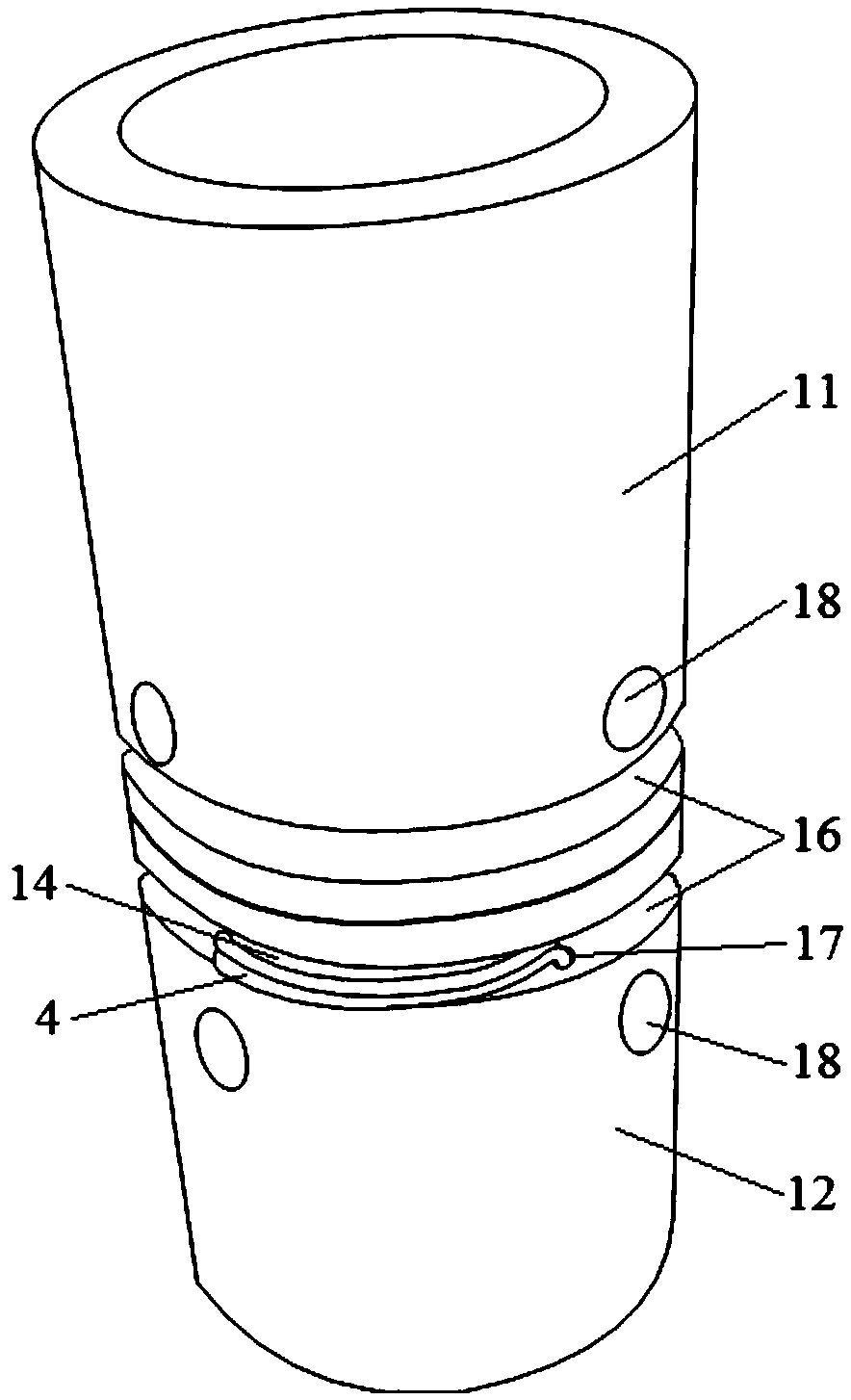

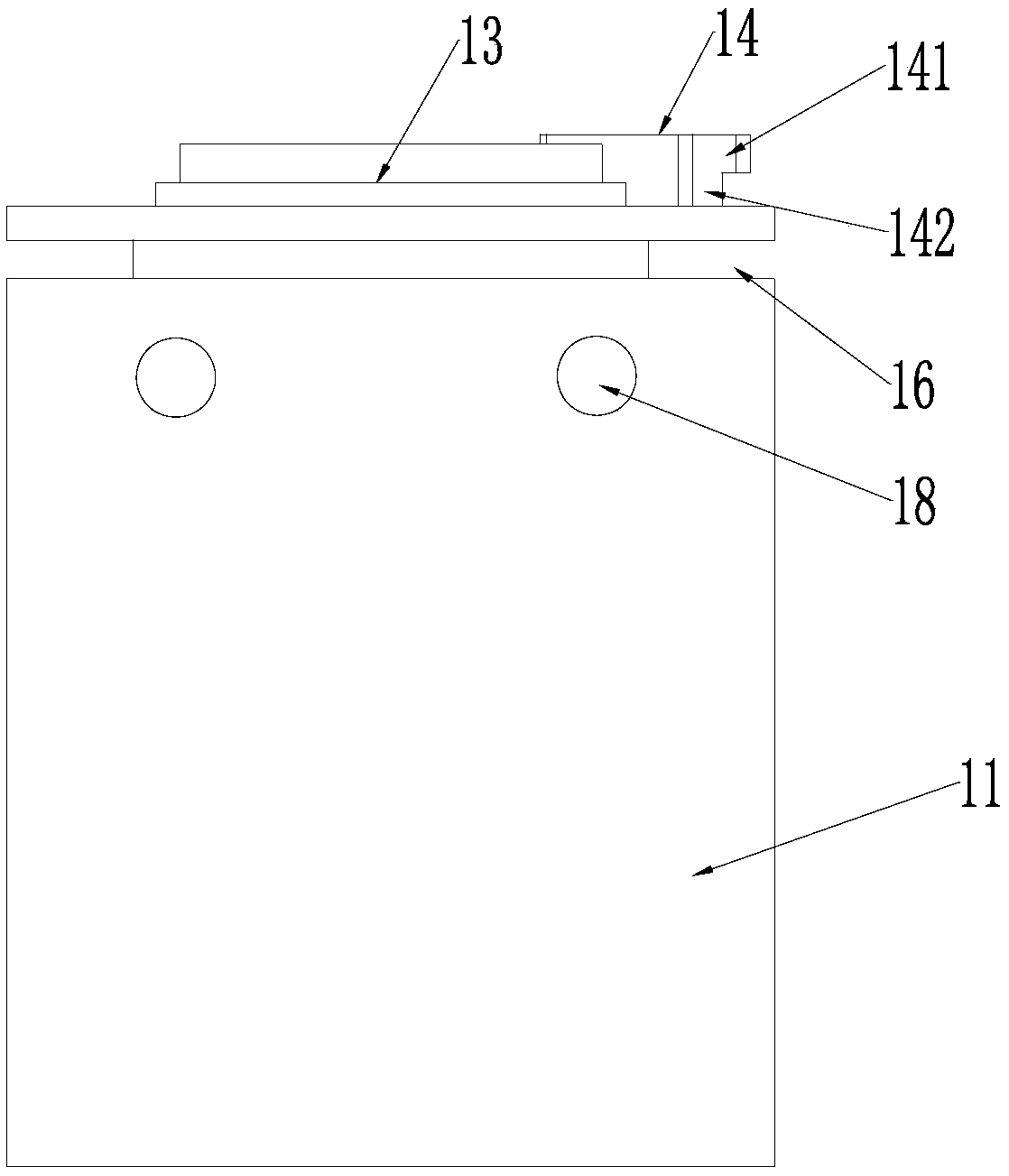

[0051] Such as figure 2 As shown in the figure, a long metal filter bag butt joint structure includes a docking card nozzle 11 and a butt joint sleeve nozzle 12 respectively arranged at the port of the metal filter bag, and one end of each metal filter bag is mutually symmetrical. Groove, the metal filter bag is connected through the cooperation and rotation of the convex groove and the groove structure, and the metal filter bag is equipped with a gasket 3 to ensure the airtightness between the pipes. Combined with auxiliary installation tools, it can help to install and dock. Spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com