Pump

A technology of impeller and casing, which is applied in the field of pumps for transporting supercritical CO2 fluid or liquid CO2, which can solve the problems of reduced service life and achieve the effects of reducing loss, preventing interference and prolonging pump life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

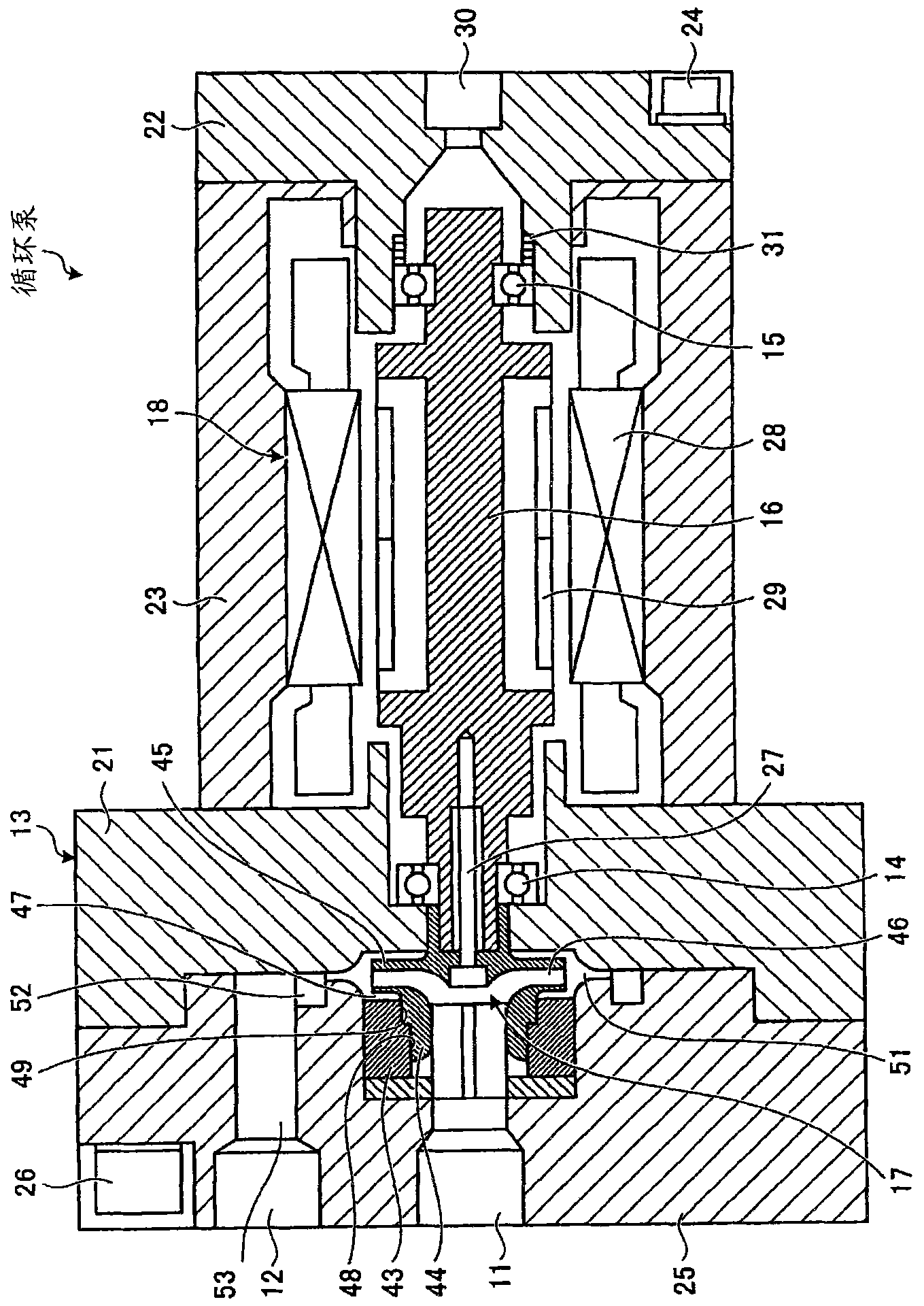

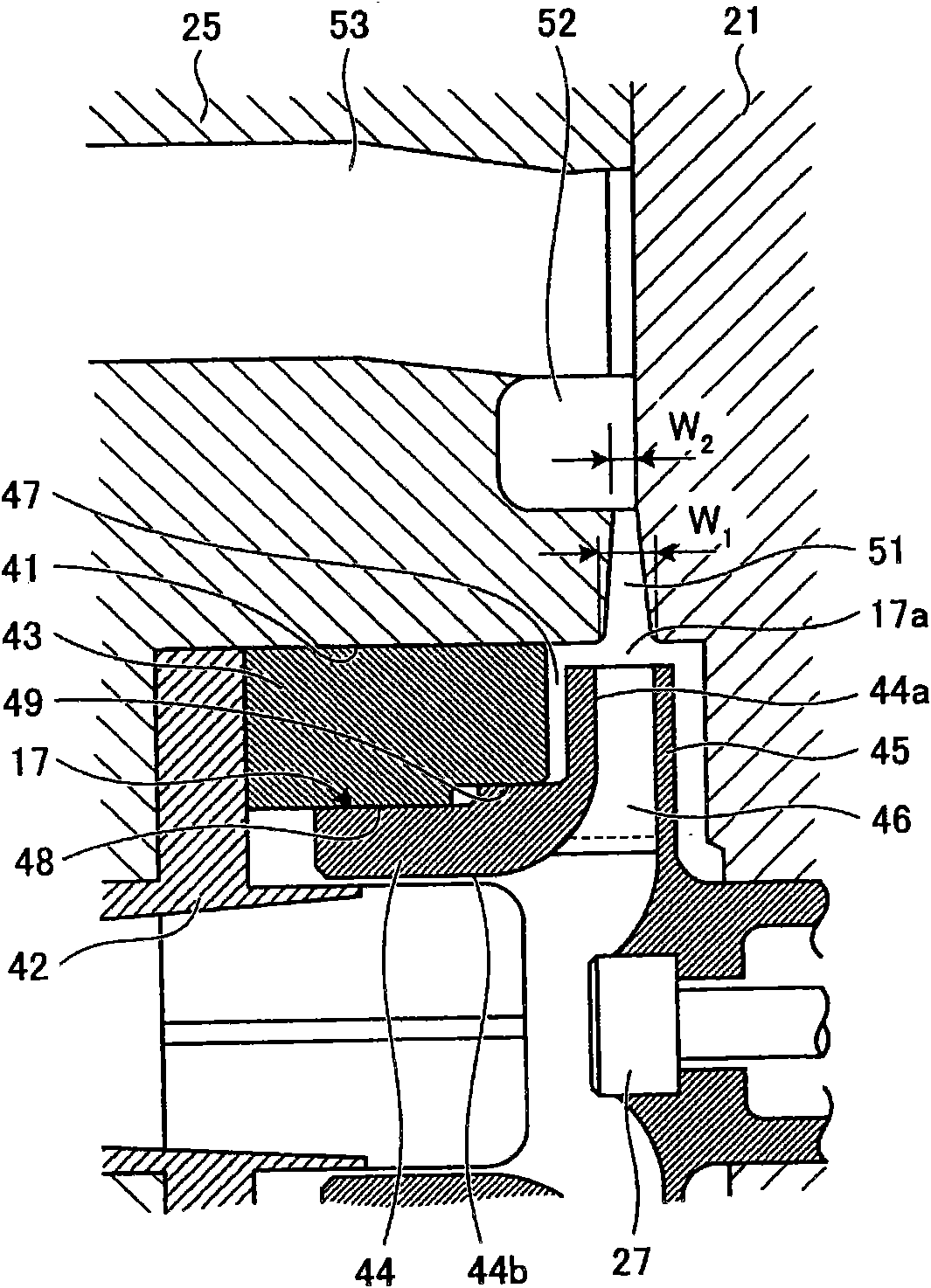

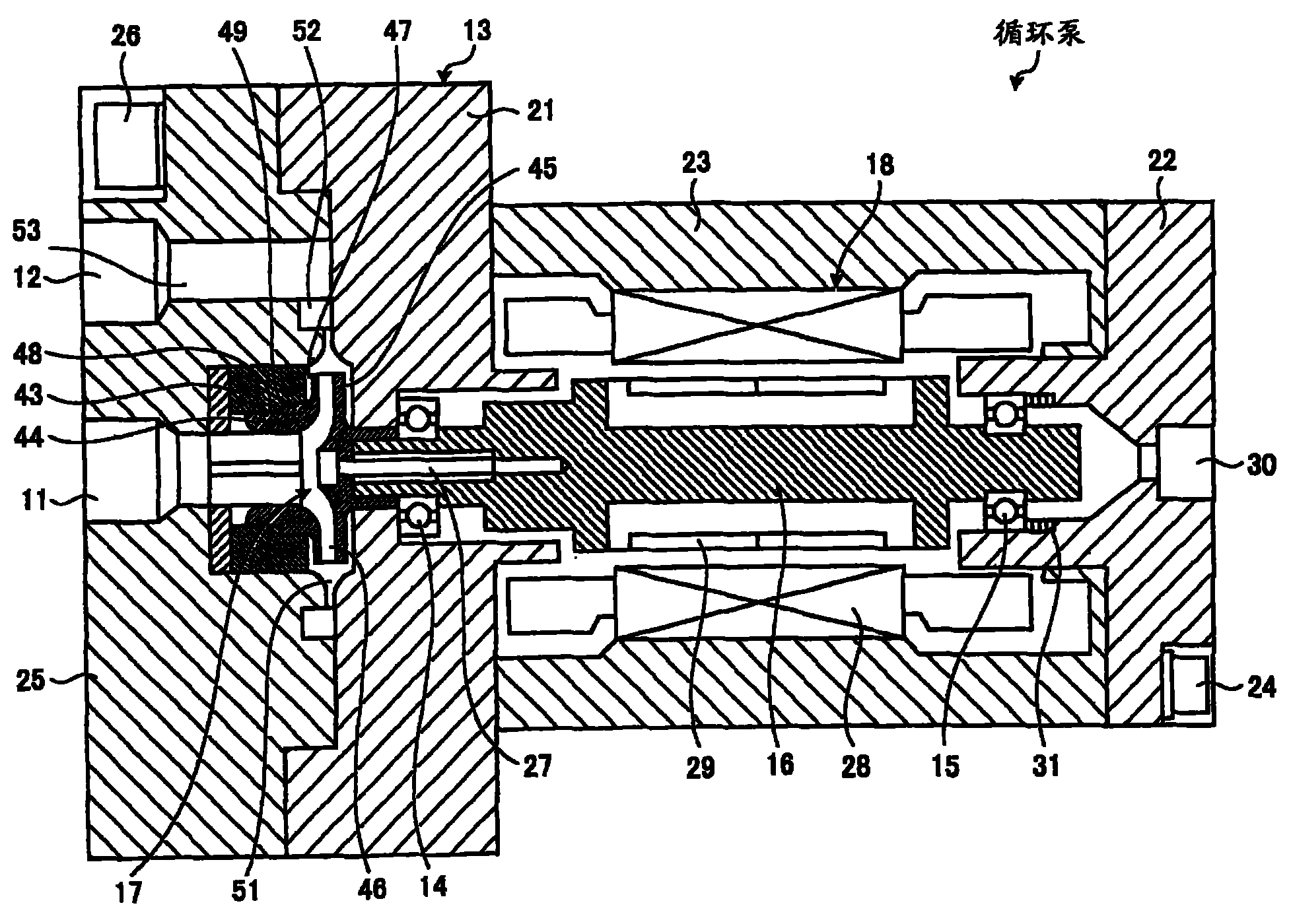

[0038] figure 1 In order to show that the pump related to an embodiment of the present invention is a cross-sectional view of a circulation pump for a semiconductor cleaning device, figure 2 It is an enlarged view showing the main part of the circulation pump for the semiconductor cleaning apparatus of this embodiment.

[0039] As shown in Fig. 1 and Fig. 2, the circulation pump for semiconductor cleaning device of this embodiment is provided with: a casing 13 having a suction port 11 and a discharge port 12; in this casing 13, ball bearings 14, 15 are used to rotate The main shaft 16 is freely supported; the impeller 17 connected to the shaft end of the main shaft 16; and the shield motor 18 capable of driving the rotating impeller 17 through the main shaft 16 are configured so that the fluid sucked by the suction port 11 can be boosted by the rotation of the impeller 17. Discharge from outlet 12.

[0040] The structure of the casing 13 is that the annular discharge and su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com