High-speed powder tablet press

A tablet press, high-speed technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve problems such as equipment resonance, achieve the effect of improving work efficiency, facilitating production, and avoiding bridging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

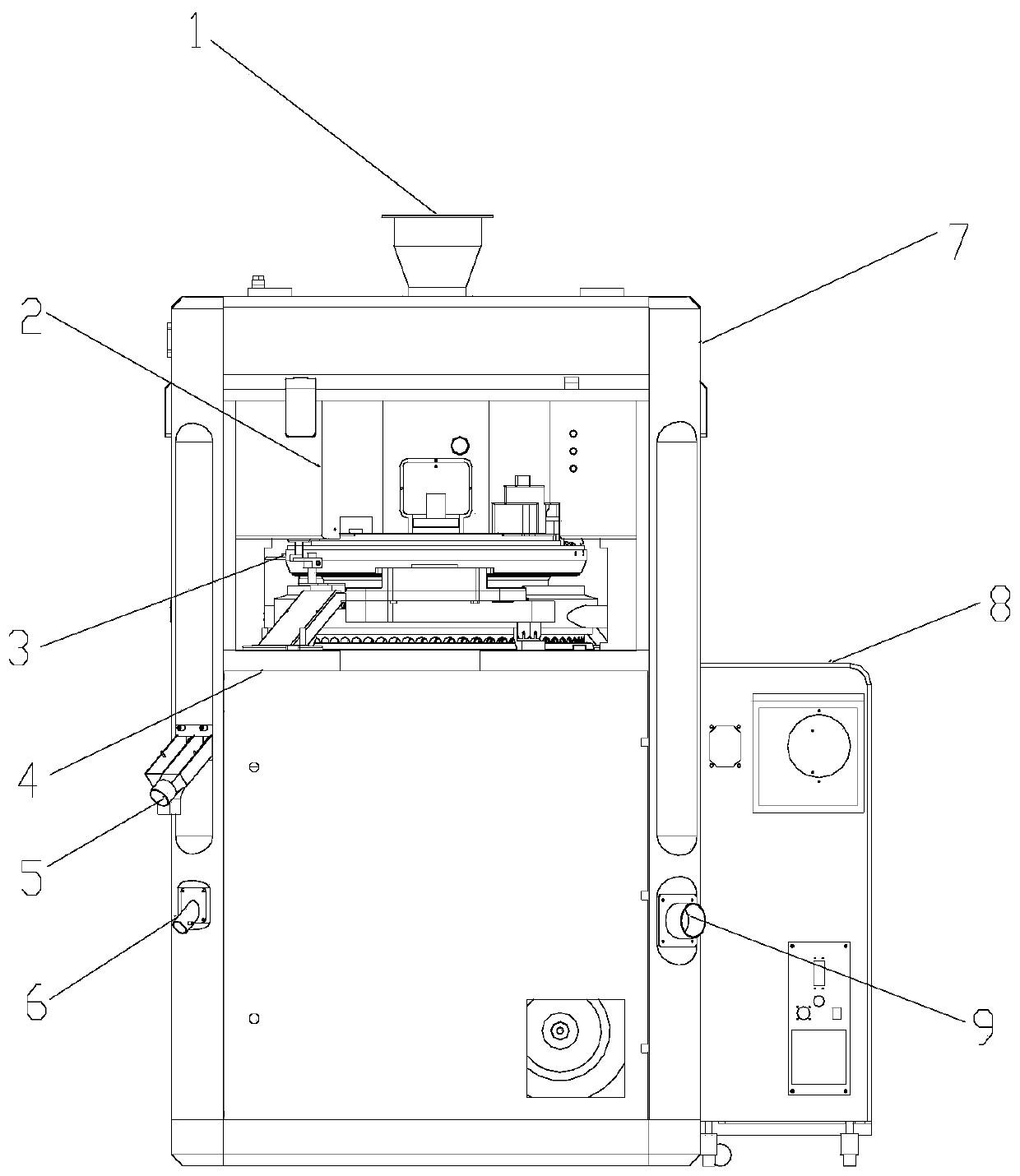

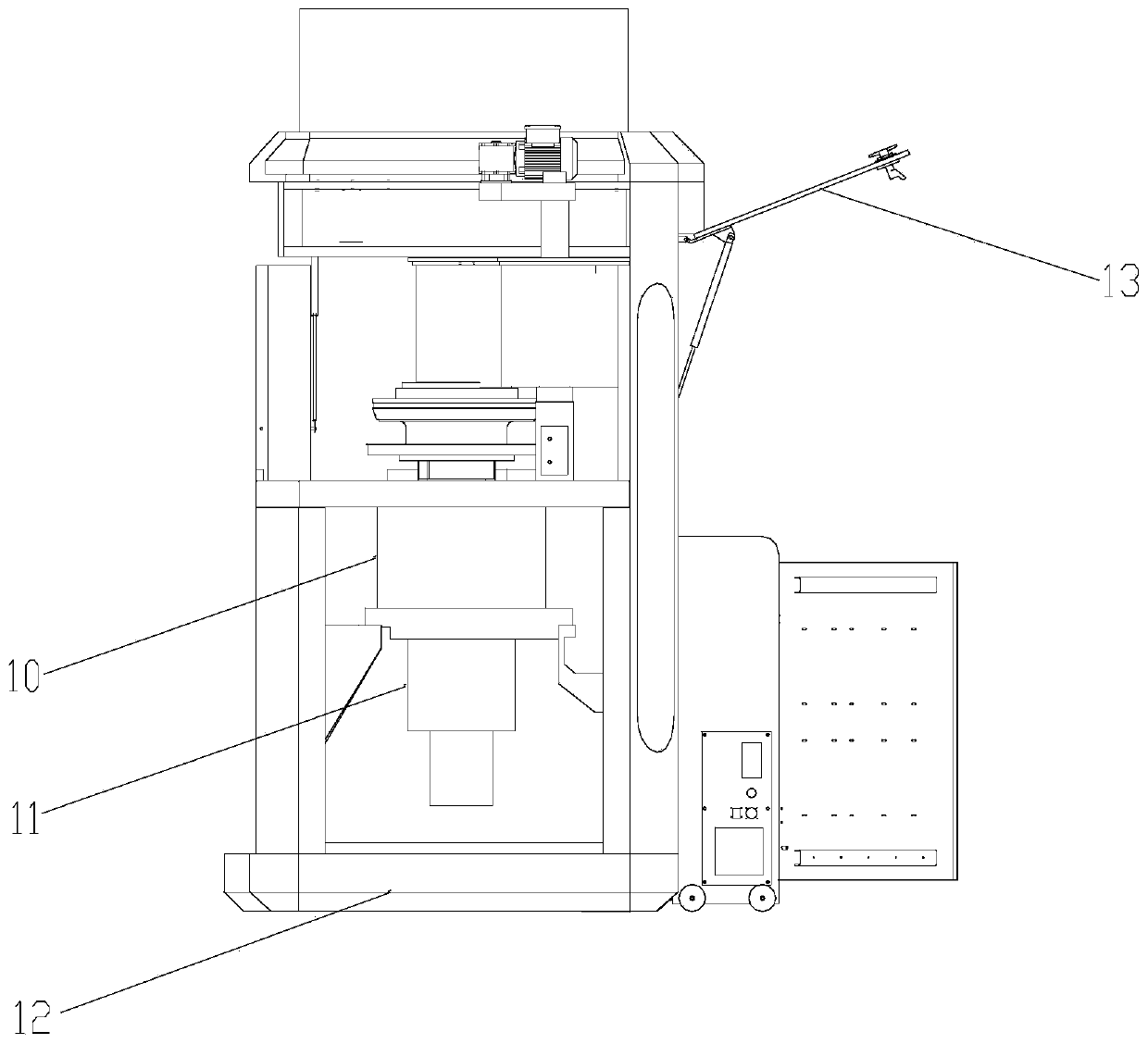

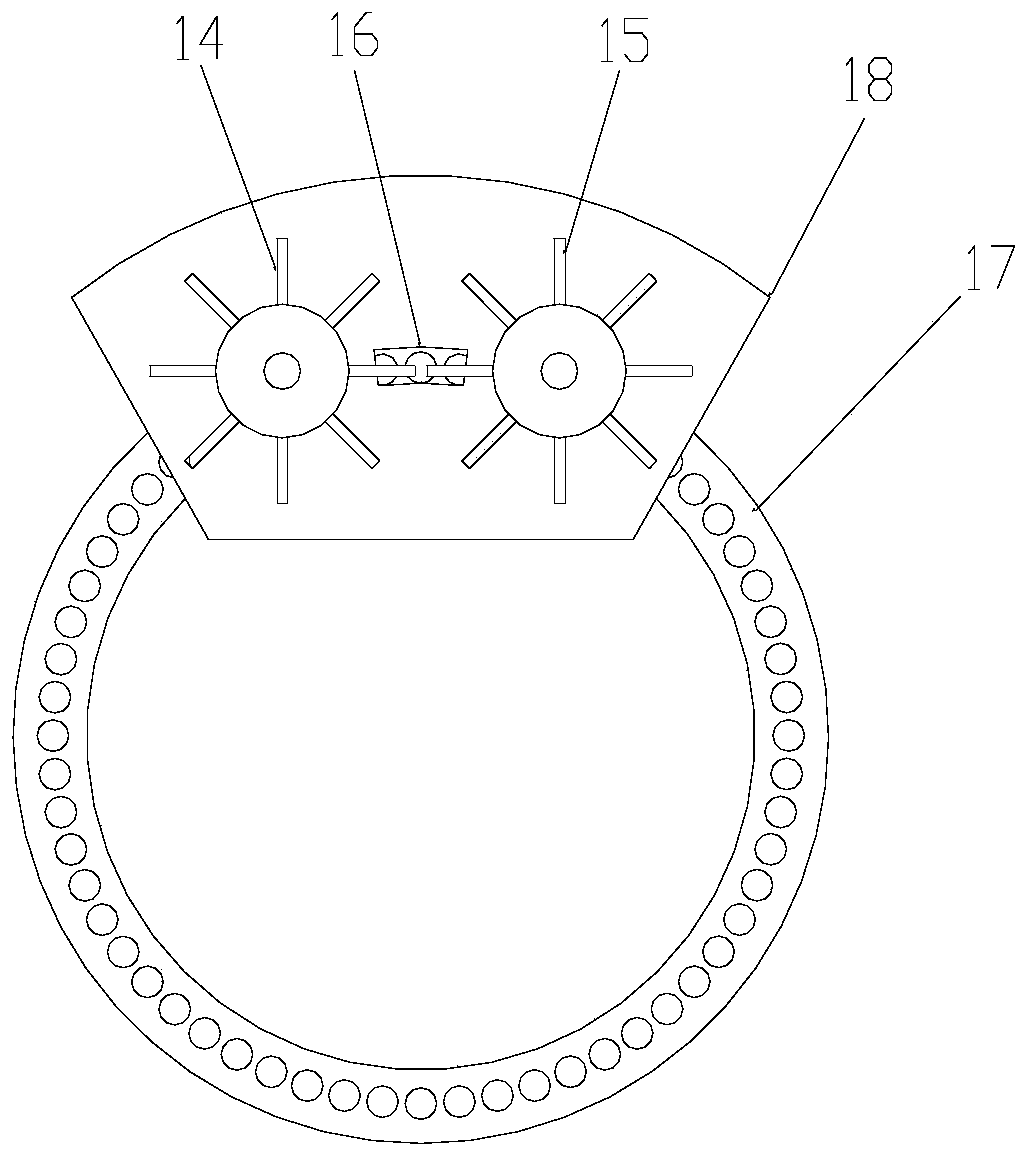

[0040] like Figure 1-Figure 11As shown, the powder high-speed tablet press provided by the embodiment of the present invention includes a frame and a rotating mechanism installed at the bottom of the frame, a liftable top tower 2 is installed on the top of the frame, and guide columns are installed on the top of the frame 28, the top tower 2 is installed on the guide column 28, and there are two guide columns 28, and the bottom of the guide column 28 is installed on the frame, and the top tower 2 is supported in 3 points by two guide columns 28 and the turret. A motor base 27 is installed on the guide post 28, and a lifting motor 29 is installed on the motor base 27. The output shaft of the lifting motor 29 is connected with a reducer, and the output shaft of the reducer is connected to the lifting guide column through a coupling. 30 connection, through the hoisting motor 29 and the speed reducer, the top tower 2 is lifted and lowered, which provides convenience for the repla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com