Tool for determining pre-tightening force of soft package battery, method for determining pre-tightening force of soft package battery and method for assembling soft package module

A soft-pack battery and preload technology, which is applied in battery assembly machines, secondary battery manufacturing, and electrical measurement, can solve the problems of not paying attention to the battery assembly process and introducing battery predictive force testing methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

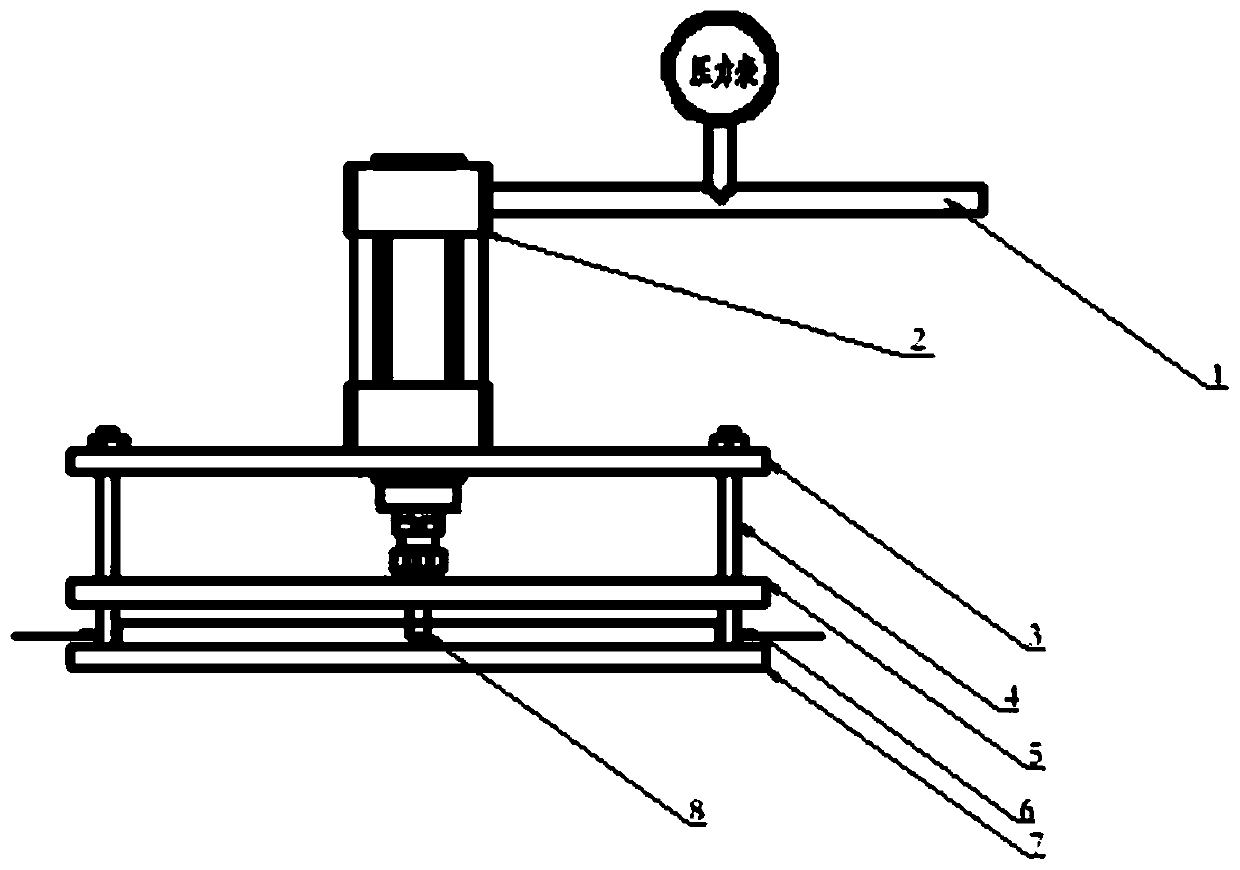

[0053] This embodiment provides a tool for determining the preload of a pouch battery. The tool includes an upper splint 5, a lower splint 7, a cylinder fixing plate 3, a cylinder 2, a pressure gauge 1, a support bolt 4, and a displacement sensor 8; The pouch battery is sandwiched between the upper splint 5 and the lower splint 7, and the lower splint 7 is connected to the support bolt 4; there are four holes on the upper splint 5 corresponding to the lower splint 7 and the support bolt 4; the cylinder fixing plate 3 passes through the support bolt 4 fixed; the cylinder 2 is fixed on the cylinder fixing plate 3 through the support bolt 4, the cylinder 2 includes a piston rod, the piston rod is in contact with the upper splint 5 and clamps the battery through the upper splint 5 when the cylinder 2 is ventilated; the pressure gauge 1 is connected with the cylinder, It is used to monitor the pressure between the pouch battery and the upper splint during the test and feed it back t...

Embodiment 2

[0055] This embodiment provides a method for determining the preload of a pouch battery using the tooling of Embodiment 1, the method comprising the following steps:

[0056] (1) Place the pouch battery between the upper splint 5 and the lower splint 7;

[0057] (2) Apply an initial pressure F to the upper splint 5 through the cylinder 2 0 The pouch battery is clamped, and the charge-discharge cycle test is performed on the pouch battery in the clamped state. During the charge-discharge cycle test, the pressure between the pouch battery and the upper splint 5 is monitored by the monitoring device, and the charge-discharge cycle is recorded. The actual pressure between the pouch battery and the upper splint 5 in the test is F 1 ; If the pressure F between the pouch battery and the upper splint 5 1 with F 0 different, the pressure information will be fed back to the pressure control device, and the pressure control device will adjust the cylinder 2 to restore the pressure bet...

Embodiment 3

[0062] This embodiment provides a method for assembling a pouch battery module, the method comprising the following steps:

[0063] (1) Stack the left side plate and the right side plate on the side of the cell pack respectively, and apply a pre-tightening force in the width direction of the module for clamping. The pre-tightening force is the pre-tightening force determined by the method described in Example 2 force;

[0064] (2) Under the condition of maintaining clamping, detachably connect the upper cover plate and the lower cover plate to the left side plate and the right side plate respectively, or connect the front side plate and the rear side plate to the left side plate respectively It is detachably connected with the right side plate, so that the upper and lower cover plates or the front and rear side plates exert continuous pressure on the left and right side plates;

[0065] (3) Release the clamping and continue to connect so that the left side plate, right side p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com