Differential housing and production method

A differential device and casing technology, applied in the direction of differential transmission, transmission, control device, etc., can solve the problem of occupying space and achieve the effect of saving structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

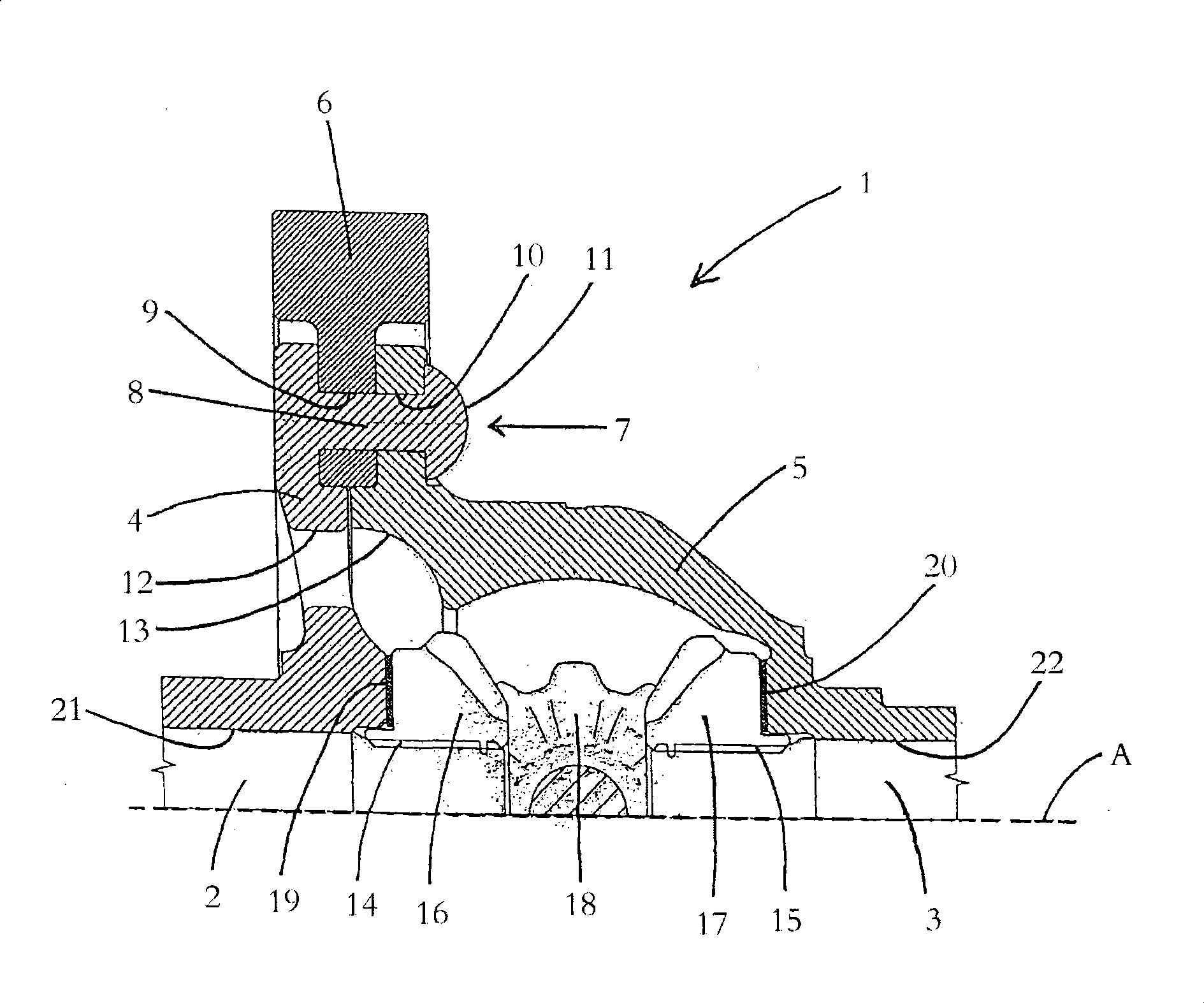

[0023] figure 1 Shows a half-sectional view of an embodiment of the housing 1 of the differential according to the invention, wherein the section plane extends through the axis A of the two coaxial driven shafts 2, 3 and thus through the center of the differential gear . The differential housing 1 comprises a housing cover 4 and a housing shell 5 , between which a drive gear 6 is clamped in a rotationally fixed manner by means of a riveted connection 7 . The riveted connection 7 is produced by means of a plurality of rivets distributed over the circumference of the housing and each integrally formed on the housing cover 4, figure 1 The sectional view of FIG. 1 shows only eight of the rivets 8 . The free end of the rivet 8 integrally formed on the housing cover 4 first passes through the bore hole 9 in the drive gear 6 and the bore hole 8 in the housing cover 5 before the free end of the rivet is deformed to establish the riveted connection 7, and at the same time the The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com